Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

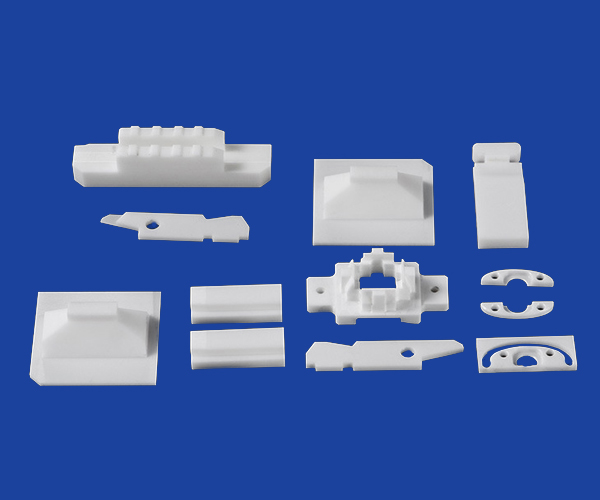

Wechat: +86 18122974730thermal conductivity ceramic plate High temperature resistant and heat insulating alumina and zirconia ceramic plates

Thermal conductivity ceramic plate have a good thermal conductivity ability for industry. thermal conductivity ceramic plate have a high hermal conductivity ceramic plate and low hermal conductivity ceramic plate. all of them depend on the raw of the ceramic plate and also depend on the customer applications.

Alumina ceramics and zirconia ceramics each have their own unique characteristics in terms of high-temperature resistance and heat insulation performance.

Even in high-temperature environments, alumina ceramics are not easy to melt or deform, and can maintain good stability at high temperatures close to the melting point. Specifically, the sintering temperature of high-purity alumina ceramics (Al₂O₃ content above 99.9%) can be as high as 1650-1990℃, and the temperature resistance range can usually reach above 1500 degrees Celsius, which can remain stable in extremely high temperature environments.

As the temperature increases, the strength and hardness of alumina ceramics will gradually decrease. Despite this, at a high temperature of 1800℃, alumina ceramics can still maintain stable performance and are suitable for high-temperature applications such as furnace linings, kiln components and heat exchangers.

Zirconia ceramics can withstand the test of factors such as high-temperature corrosion, oxidation and thermal shock, ensuring the normal operation of equipment and extending its service life.

The thermal conductivity of alumina ceramics is relatively high at room temperature, about 20~30W/(m·K). However, as the temperature rises, its thermal conductivity will continue to decrease. For example, at 1200℃, the thermal conductivity of alumina is only about half of that at 400℃. The thermal conductivity of zirconia ceramics is extremely low, which means that it can effectively prevent the transfer of heat, thus achieving excellent thermal insulation. Its excellent thermal insulation properties make it an ideal choice for manufacturing thermal insulation ceramic structural parts.

The thermal insulation properties of zirconia ceramics are particularly important in high temperature environments. For example, in the aerospace field, aircraft engines and spacecraft components need to operate in extremely high temperature and high pressure environments, and the high temperature resistance and stability of the materials are extremely high. Zirconia ceramics have become an ideal material for these components due to their excellent high temperature resistance and thermal insulation properties, effectively improving the durability and service life of the equipment.

Dimension :

Maximum length as 450mm; Thinnest thickness as 0.2mm; Widest width as 450mm. we can support to custom other type and sizes of the thermal conductivity ceramic plate.

Shape:

Rectangle, square, circle, semicircle, irregular, customizable

Materials of thermal conductivity ceramic plate we can offer:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide (SiC)

· Silicon Nitride (Si3N4)

· MSZ: Magnesia partially stabilized Zirconia (ZrO2)

· YSZ: Yttria partially stabilized Zirconia (ZrO2)

· ZTA: 80% Al2O3+20% ZrO2

· Aluminum Nitride (AlN)

· Mullite...

Customization & Machining Service:

As a thermal conductivity ceramic plate manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about thermal conductivity ceramic plates,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS