Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

|

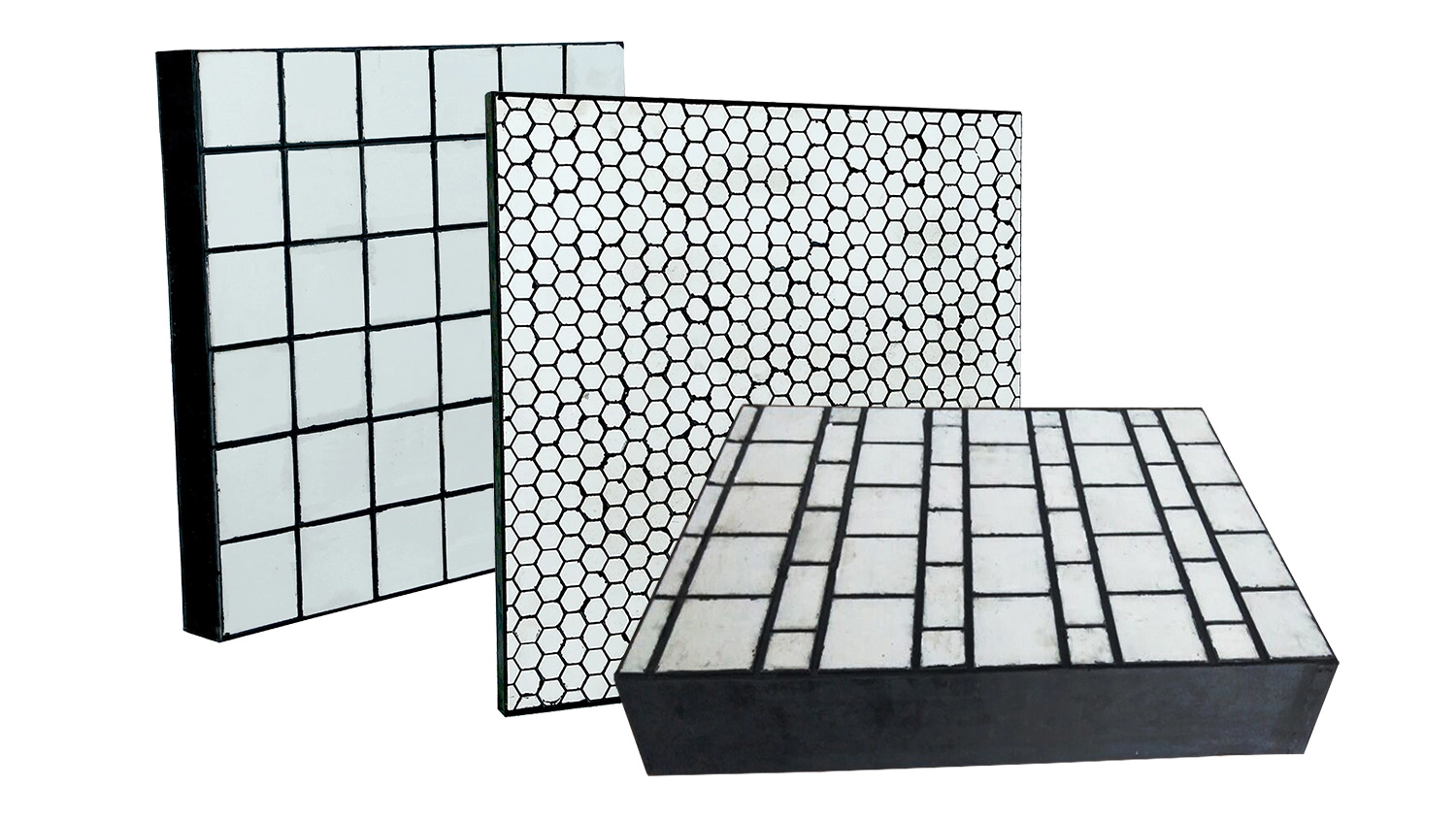

Features and Benefits · Advanced Hard Ceramic Wearplate · Easy To Install · Reduces Noise · Unsurpassed Resistance · Impact Resistant · Smooth Surface · Longest Wear Life Available |

|

Wear Liner is mainly used in the mining and quarrying industries, where severe abrasion occurs and the angles of impact are low.

Ceramic wear-resistant liner are made of extremely hard ceramic materials that provide unparalleled wear resistance,excellent Corrosion and High Temperature resistant.

|

Normal size:

500*500*30 300*400*32 500*500*40

316*476*60 188*300*30 300*300*25

Dimension : ·Inside Diameter as small as 0.3 mm ·Inside Diameter tolerance we could make as fine as 0.002mm ·Outside Diameter tolerance as fine as 0.001mm |

Additional Information:

·Discounts on large quantities of Ceramic tube ·In stock items will typically ship in a few working days. ·Unit price and estimated ship dates will be calculated when the length and quantity are specified. ·We can be custom / OEM For the liner tube / pipes |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic liner,plates,sheet or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS