Ceramic shaft alumina zirconia high precision technical shaft rod

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

Ceramic Shaft Alumina Zirconia High Precision Technical Shaft Rod

Ceramic Parts and components manufacturer,OEM

High Quality, High Precision, Delivery on time, Factory Price

Ceramic shaft is a ceramic material with ceramics as the main body, which is used in thick film integrated circuit.ceramic shaft has good conductivity, mechanical strength and high temperature resistance.It is important to note that the need for ultrasonic washing.ceramic shaft is a widely used ceramic, because of its superior performance, in the mechanical field has been more and more widely used, to meet the needs of daily use and special performance.

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

After sintering, ceramic shaft material still needs finishing.Zirconia ceramic shaft parts require a high surface finish, mirror-like, to increase lubricity.Due to the high hardness of zirconia ceramic shaft material, it needs to be processed with harder abrasive polishing brick material.Such as SIC, B4C or diamond, etc.Grinding is usually carried out with coarse to fine abrasive, and the final surface is polished.

Ceramic parts with wear resistance, super strong, super hard, high temperature resistance (refractory), super corrosion resistance, never rust, oxidation resistance, insulation, its own lubrication and other excellent performance.

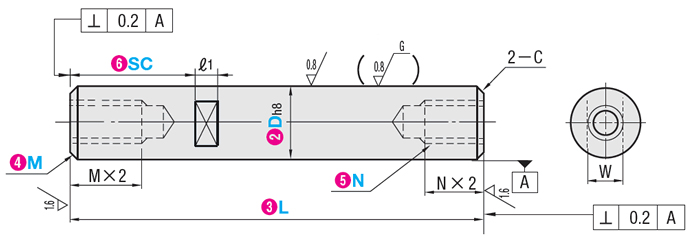

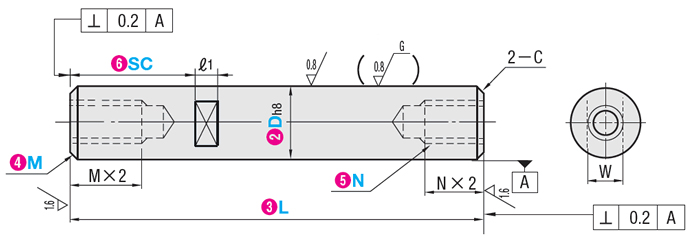

Part of the available maching specifications:

|

Diameter of axle D |

Length L |

Internal thread M |

|

(φ) |

(mm) |

(mm) |

|

6 |

20 ~ 600 |

3 |

|

8 |

20 ~ 800 |

3 ~ 5 |

|

10 |

20 ~ 800 |

3 ~ 6 |

|

12 |

20 ~ 1000 |

4 ~ 8 |

|

25 |

35 ~ 1200 |

4 ~ 16 |

|

25 |

35 ~ 1200 |

4 ~ 16 |

Tips: As a professional manufacturer of ceramic structural parts, we provide customized services to customers.OEM

Ceramic pump material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Ceramic shaft precision process:

|

Precision of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Smoothness |

Highest possible mirror |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized |

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surface |

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

|

|

Ceramic Parameter:

|

Properties |

Units |

AL2O3 |

ZrO2 |

SiC |

Si3N4 |

|

Density |

g/cm3 |

3.65-3.93 |

5.95-6.0 |

3.12 |

3.23 |

|

Water absorption |

0 |

0 |

0 |

0 |

0 |

|

Coefficientof thermal expansion |

10-16/k |

7.9-8.5 |

10.5 |

3 |

3.2 |

|

Modulus of elasticity young`s mod |

GPa |

280-340 |

210 |

440 |

300 |

|

Poission`s ratio |

/ |

0.21-0.22 |

0.3 |

0.17 |

0.26 |

|

HV hardness hv |

MPa |

1650 |

1300-1365 |

2800 |

1500 |

|

Flexural strength |

MPa |

310 |

950 |

390 |

720 |

|

Flexural strength(700℃) |

MPa |

230 |

210 |

380 |

450 |

|

Compressive strength |

MPa |

2200 |

2000 |

1800 |

2300 |

|

Fracture toughness |

MPa*m1/2 |

4.2 |

10 |

3.9 |

6.2 |

|

Heat conductivity |

W/m*k |

26-30 |

2-2.2 |

120 |

25 |

|

Electrical resistivity |

Ω*mm2/m |

>1016 |

>1015 |

>103 |

>1013 |

|

Max use temperature |

℃ |

1750 |

1050 |

1550 |

1050 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

high |

|

Dielectric constant |

/ |

9.6 |

29 |

9.66-10.03 |

/ |

|

Dielectric strength |

KV/mm |

8.7 |

9 |

/ |

/ |

|

Thermal shock resistance |

△T(℃) |

180-220 |

280-350 |

230-260 |

/ |

|

Tensile strength |

MPa |

248 |

250 |

/ |

/ |

|

Customization & Machining Service:

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic shaft or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730