Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Custom Alumina Zirconia ceramic mould injection parts

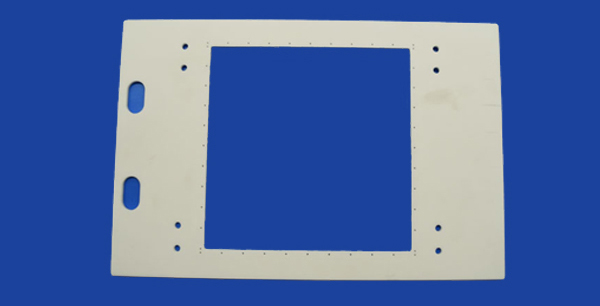

High precision Alumina Zirconia Ceramic Mould Injection Parts OEM

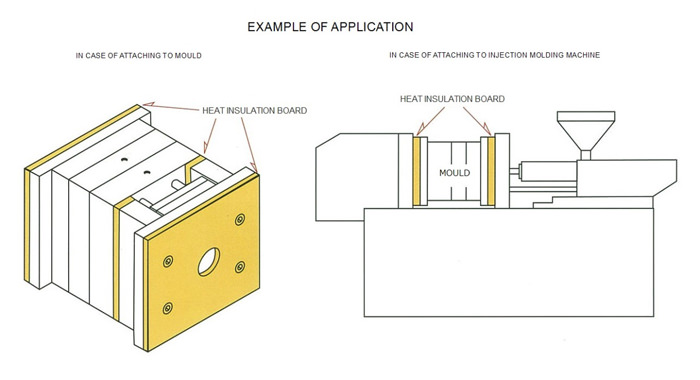

The high temperature insulator plate sheet for injection mold is used for the mold between the top clamping plate and the fixed plate, as well as the mold between the bottom of the injector housing and the movable plate.The unique asbestos-free glass reinforced polymer composite's thermal insulation performance can inhibit heat transfer from mold to platen or from platen to mold (depending on the application), which helps to save energy and extend machine life.High temperature insulator plate has excellent nondeforming characteristics and higher compressive strength than asbestos and mica.

The main materials of the injection ceramic plate:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

US offers a wide variety of high temperature injection ceramic insulator plate sheet manufactured from high-performance technical ceramic materials, including alumina, zirconia, and silicon carbide. Enhance performance and product life by using the material best suited to your application.

The normal dimensions of blank material of heat insulation(thermal insulation) board(include but not limited belows)

Thickness : 0.1~100mm

Length × Width : 900×1200 mm, 1000×1000 mm, 1000×2000 mm, etc.

Dimensions (thickness, length, width) of the heat insulation(thermal insulation) board are different for each material.

Parts of ue oem dimensions(include but not limited belows)

|

18 x 36 x 1/2 thk High temp insulator sheet |

|

24 x 36 x 1/4 thk High temp insulator sheet |

|

24 x 36 x 1/2 thk High temp insulator sheet |

|

36 x 36 x 1/4 thk High temp insulator sheet |

|

36 x 36 x 1/2 thk High temp insulator sheet |

|

48 x 96 x 1/4 thk High temp insulator sheet |

|

48 x 96 x 1/2 thk High temp insulator sheet |

The length, thickness , diameter and shape of the ceramic plates are customized.

Features Of Heat Insulation(Thermal Insulation) Board

1. Since the temperature distribution of a mould(mold) becomes fixed, the quality of products, such as accuracy of dimension and appearance, improves.

2. The operating ratio of an injection molding machine improves by shortening the waiting time of a mould(mold) temperature rise.

3. By reduction of the heat conduction from a mould(mold) to an injection molding machine, distortion of an injection molding machine decreases and the durability of an injection molding machine improves.

4. As the heat dissipation from the die plate (platen) of an injection molding machine is decreased, it becomes energy saving.

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS