Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730Zirconia ceramics and alumina ceramics are two widely used ceramic materials, so what is the difference between zirconia ceramics and alumina ceramics? Now let Mingrui Ceramic solve your doubts.

Zirconia ceramics and alumina ceramics are two widely used ceramic materials, so what is the difference between zirconia ceramics and alumina ceramics? Now let Mingrui Ceramic slove your doubts.

Introduction

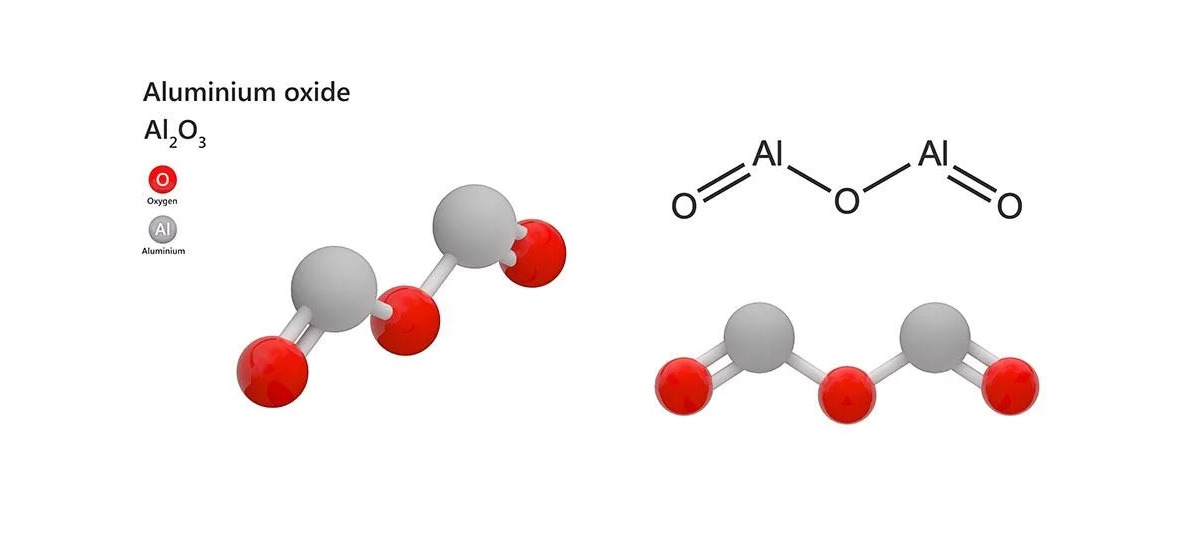

Alumina ceramic is a kind of ceramic material based on alumina (Al2O3), which is used in thick film integrated circuits. Alumina ceramics have good conductivity, mechanical strength and high temperature resistance.

Alumina ceramic is a kind of ceramics with a wide range of uses. because of its superior properties, alumina ceramics have been more and more widely used in modern society to meet the needs of daily use and special properties.

Application

Alumina ceramics are divided into two types: high purity type and ordinary type.

High purity alumina ceramics are ceramic materials with an Al2O3 content of more than 99.9%. Because their sintering temperature is as high as 1650℃ ~ 1990℃ and transmission wavelength is 1 ~ 6 μ m, molten glass is generally made to replace platinum crucibles; its light transmittance and alkali resistance can be used as sodium lamps; it can be used as integrated circuit substrates and high-frequency insulating materials in the electronic industry.

Introduction

Zirconia ceramics (ZrO2 ceramics) have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and electrical conductivity at high temperature.

Pure ZrO2 is white, yellow, or gray when containing impurities, generally containing HfO2, is not easy to separate. The proven zirconium resources in the world are about 19 million tons. Zirconia is usually made from zirconium ore purification.

Application

Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high bending strength and high wear resistance, excellent thermal insulation, and thermal expansion coefficient close to steel.

The main products are: Y-TZP grinding balls, dispersed and grinding media, nozzles, ball valve ball seats, zirconia molds, miniature fan shafts, optical fiber pins, optical fiber sleeves, wire drawing dies and cutting tools, clothing buttons, watch cases, and straps, bracelets, and pendants, ball bearings, light golf clubs, and other room-temperature wear-resistant zero devices, etc.

The zirconia ceramic structure has a higher surface finish, mirror shape, extremely smooth, its friction coefficient is lower than that of alumina ceramics.

In addition, the toughness of the zirconia ceramic structure is excellent, which overcomes the inherent brittleness of the ceramic itself, the wear resistance is higher, the working life of the product is greatly extended.

Zirconia ceramic structural parts is a newly developed structural ceramic second only to alumina ceramics. Zirconia ceramic structure has been paid more and more attention because of its good properties, such as its fracture toughness is higher than that of alumina ceramics.

If you found this article helpful, please let us know by following our Facebook!

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS