Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Rolling ceramic bearings are widely used in ball screw elevator.We know that the ball screw elevator rolling ceramic bearings wear out easily.Make sure that this will help you with this difficulty.

I. Analysis of common problems caused by abrasion of rolling ceramic bearings on ball screw elevator

The rolling ceramic bearing is the result of overheating caused by the operating environment of the ball screw lift.Its main performance is: the rolling ceramic bearing working temperature requirements are too high, rolling ceramic bearing using rotary rest or internal peripheral equipment caused;The rolling ceramic bearing and ceramic bearing with seat are swollen, and the system is jammed.Too high temperature makes rolling ceramic bearing different heat treatment.The reasons are as follows:

1. Angular momentum of helical gear transmission is too small.

2. Unqualified lubrication or improper lubrication management.

3. Insufficient oil on ball screw lift.The air pollution is serious.

4. Improper internal clearance of rolling ceramic bearing.

5. The scheme design specifications, models and standard tolerances exceed the standard, resulting in the inner and outer deformation of the rolling ceramic bearing, and the unbalanced load of the stress field of the roller ceramic bearing is serious, with large load and friction loss power.This results in heating of the rolling ceramic bearings of the screw extruder bucket elevator.

6. Installation and construction techniques and methods may be incorrect, resulting in rolling ceramic bearing skew.

Secondly, the ball screw elevator wear out rolling ceramic bearing solution:

1. Uranium channeling angular momentum should be strictly managed and controlled and not too small when installing ball screw elevator.Run together after the production process to carefully analyze and check, check to prevent the occurrence of an illusion.

2. Use grease.Apply and remove lubricating greases as required to ensure the wholesale quality of refined oil products. Remove air pollution and moldy lubricating greases frequently.

The grease should not be added too much or too little to prevent the grease from losing after the temperature rises.

4, according to the standard selection of ball screw elevator rolling ceramic bearing internal clearance.

5. Rationally design different specifications and models to avoid errors in manufacturing specifications and models;A reasonable rolling ceramic bearing is selected.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

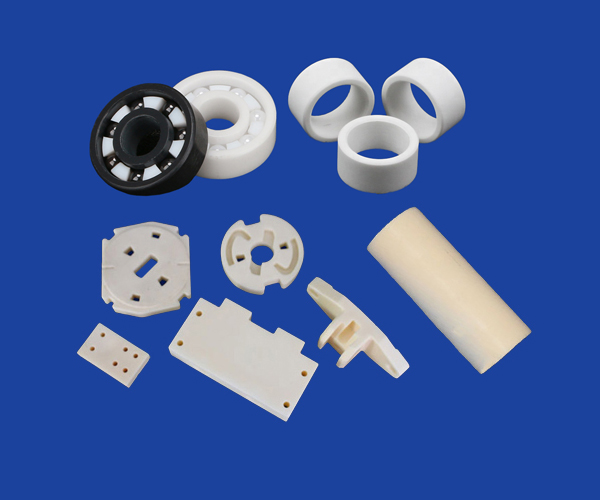

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS