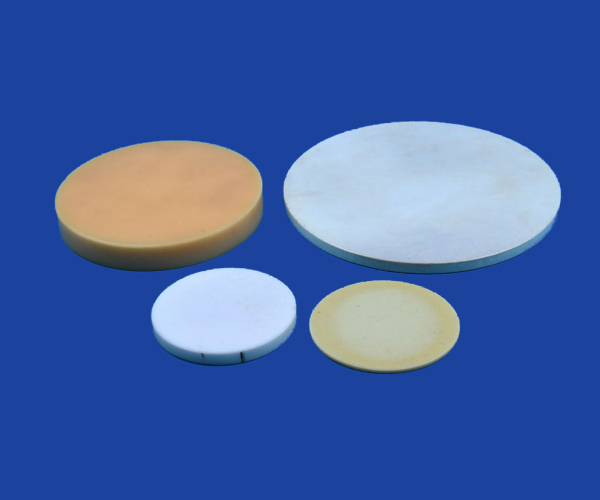

Solar panel components for ceramic circuit board applications

The solar AC power generation system is composed of a solar cell component, a charging controller, an inverter and a battery. The conversion efficiency of the photovoltaic inverter directly affects the amount of power generated by the solar power system during the life cycle.

Usually, the process of converting DC power into AC power is called inverter, and the device that implements the inverter process is called inverter, also called power regulator. The photovoltaic inverter not only has the function of electric energy conversion, but also maximizes the performance of solar cells and system fault protection functions, including automatic operation function, shutdown function, automatic voltage adjustment function, DC detection function and separate operation function. .

Photovoltaic inverter is a key component in solar cell modules, so in order to better play the role of solar cells, there are high requirements for photovoltaic inverters, not only the regulation of photovoltaic inverter production design, but also in photovoltaic The internal parts of the inverter must be purchased in accordance with strict standards.

Whether the PV inverter can be perfectly reflected is closely related to its core “inverter circuit”. In order to improve the efficiency of the inverter circuit, manufacturers have abandoned the traditional circuit board and adopted the most stable and reliable ceramic circuit board.

Ceramic substrates have great advantages:

1. Higher thermal conductivity. The thermal conductivity of the traditional aluminum-based circuit board MCPCB is 1~2w/mk, the thermal conductivity of the alumina ceramic is 15~35 w/mk, and the thermal conductivity of the aluminum nitride ceramic is 170-230 w/mk, aluminum. The copper/aluminum in the copper-based circuit board has a high thermal conductivity, but the aluminum/copper-based circuit board has an insulating layer, which causes the thermal conductivity of the entire board to decrease. The ceramic circuit board uses a ceramic piece as a substrate, and does not require an insulating layer, and the heat on the copper line is directly transmitted to the ceramic piece to better dissipate heat;

2. Good conductivity, the copper layer does not contain an oxide layer. The ceramic circuit board can be made of thick copper, does not contain an oxide layer, and has better electrical conductivity than the copper layer of the sintering process;

3, can be through the double-sided conductive. The ceramic circuit board can be perforated on the substrate to achieve positive and negative electrical conduction.

This is not possible with ordinary ceramic plates.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730