Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Thanks to our processing and manufacturing capabilities,mingrui is able to offer a wide range of standard and customized advanced ceramic insulators. us offers a variety of unique engineering features to improve or extend product performance.

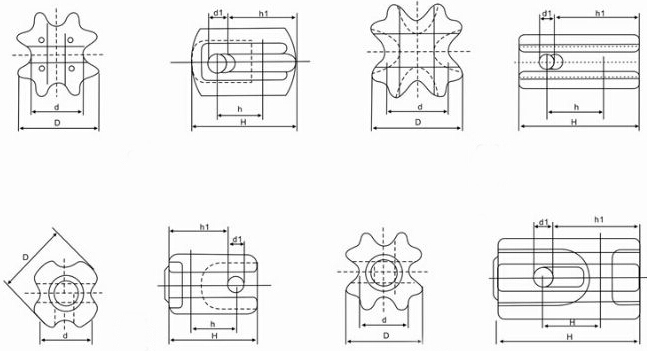

Part of machining case specifications:

Electrostatic Insulator Applications:

Power Generation- Coal-fired and oil-fired plants

Rock Products Processing Plants-Portland cement, lime, etc.

Pulp, Paper, and Wood Products Mills- salt, cake and wood waste boilers

Chemical Processing Plants- Sulfuric acid de-misting, etc.

Steel Mills-Iron ore sinter plants, coal coking plants, open hearth, and basic oxygen furnaces

Nonferrous Metals Processing Plants- Copper smelting

Oil Refineries- Catalytic cracker units

Municipal and industrial Waste

Incineration Plants

High purity alumina ceramics:

99.99% Alumina ceramic; 99.9% Alumina ceramic

Ordinary alumina ceramics:

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic.

Alumina Reliability:

Better wear resistance

Higher volume resistivity

Greater mechanical strength

More chemically inert

...

|

Ceramic Precision Process: Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

|

Alumina Ceramic Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Customization & Machining Service:

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of alumina ceramic sheets or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS