insulation of ceramic parts

Time: 2019-01-19 Writer: mingrui

Basic properties and phenomena of insulation of ceramic parts

Basic insulating materials and structural characteristics of ceramic parts;Apply the main parameters;Application principle and examples;

Insulation materials and dielectric;

Quantitative description of ceramic insulation parameters: volume resistivity and dielectric strength

When the dielectric material is used in the electric field, it often loses its insulating ability and breaks down because the voltage it bears exceeds a certain value.

Including electric breakdown, thermal breakdown, chemical breakdown and other reasons.

Dielectric breakdown: a strong electric field causes a rapid increase in current;Partial melting, burning, evaporation or damage;Dielectric loss of insulation characteristics, into a conductive body, called the dielectric breakdown.

Dielectric strength (collapse strength) : electric field causing dielectric collapse (kv.mm-1);

The dielectric breakdown field strength is called the breakdown field strength

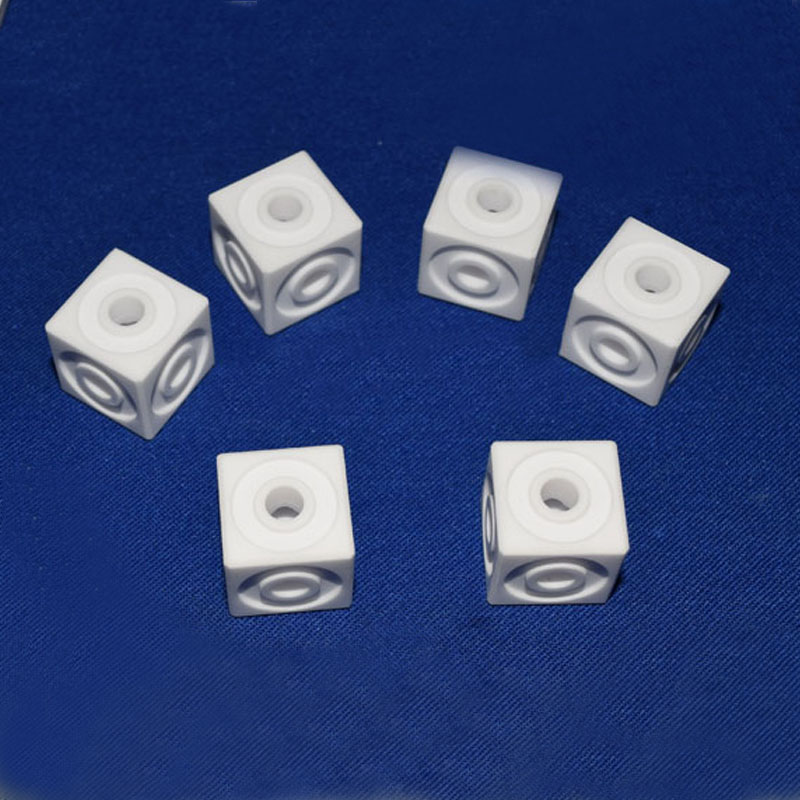

Insulating ceramics, also known as device ceramics, are ceramic materials used in electronic equipment for installation, fixation, support, protection, insulation, isolation and connection of various radio components and devices.

To be an excellent insulating ceramic, it must have the following properties:

1. High volume resistivity or 1012 Ω m.;

2. The small relative dielectric coefficient is 30 for the groups under the condition of 30.

3. Loss factor tg 0.001;

4. High dielectric strength 500kV/cm

Good thermal conductivity: thermal conductivity is 24 ~ 28W/m·K;

Corrosion resistance, no deformation, can be in 55 ℃ ~ + 860 ℃ temperature range use;

Good mechanical properties;

Thermal expansion coefficient as consistent as possible with semiconductor materials.

Insulation mechanism of insulating ceramics

The solid energy band is called full band if it is fully occupied by electrons, the one not occupied by electrons is called conduction band, and the one between full band and conduction band is called forbidden band.If the forbidden band width is large enough (more than a few evs), the electrons with a full band will be difficult to be excited beyond the forbidden band and into the conduction band, that is, the electrons can hardly be transferred, then the solid is a typical insulator

Traditional insulating porcelain

Talc porcelain: it is made of talc (3MgO·4SiO2·H2O) as the main raw material and sintered with clay, bentonite and barium carbonate at high temperature.

The dielectric coefficient is low (6 ~ 7).

The breakdown strength is 200 ~ 300kV/cm;High insulation resistance, 1012 Ω m.;

Low thermal conductivity: 2.1w /m·K

Magnesium peridot porcelain: 2MgO·2Al2O3·5SiO2

Mullite porcelain: 3Al2O3·2SiO2

Ordinary electric porcelain is produced by the conventional technology of silicate ceramics.The sintering temperature of 1250 ~ 1320 ℃.

Main applications: IC substrate electronic devices development trend: electronic equipment miniaturization technology development in integrated circuits, the substrate plays the role of carrying thick film elements, interconnection, external components and packaging, etc., in high-power circuits, the substrate has the role of heat dissipation.

Circuit requirements for the substrate include: flatness, high finish;Good electrical performance;High thermal conductivity;Having the thermal expansion coefficient matching with other materials;Good mechanical properties;High stability;Good machining performance;The price is cheap.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730