Ceramic screws application

Time: 2019-01-19 Writer: mingrui

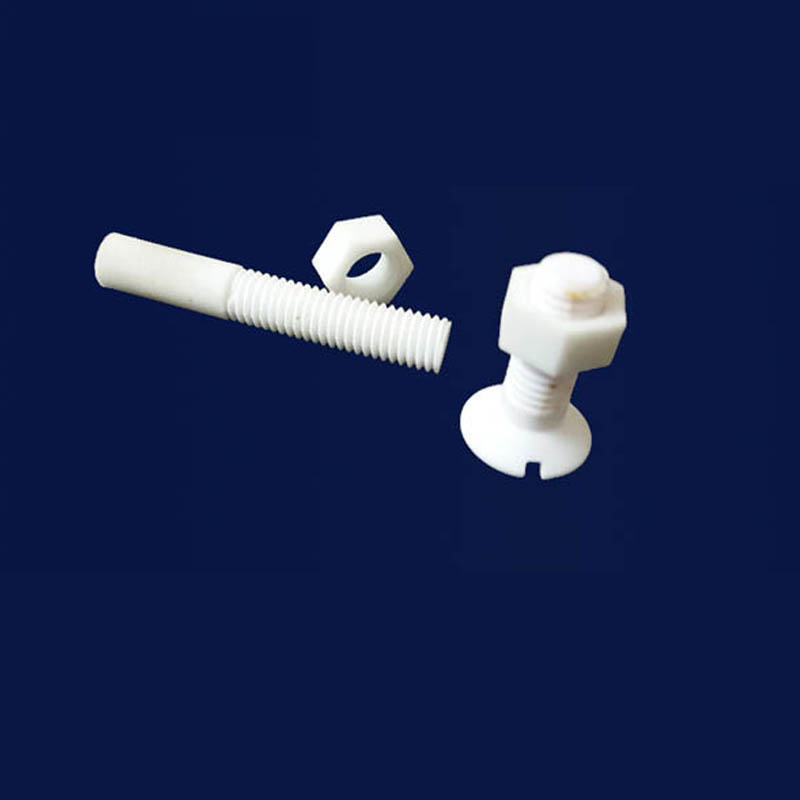

Performance and application of ceramic screws

Ceramic screw is made of zirconia, alumina, silicon nitride and other materials screw products, which has a relatively stable physical stability and chemical stability, physical stability is mainly manifested in high and low temperature resistance, insulation, antimagnetic, wear resistance and other aspects;Chemical stability is mainly in the surface corrosion resistance, oxidation resistance.However, because it is a hard brittle material, its mechanical properties can not be compared with metal materials.Of course, with the improvement of material technology and product structure, this gap is gradually narrowing.

Physical stability of ceramic screws

High low temperature characteristic

Does not deform or extend at high temperature (800 c) and does not reduce the strength of the connection.It can be kept at minus 70 degrees

Good connection strength.

Insulation characteristics:

Zirconia ceramic screws maintain good insulation at room temperature.At room temperature, the resistivity is 10, and when heated in air to a certain temperature range (above 800 degrees), the insulator can become a conductor of electricity.

The magnetic properties of the Zirconia screws and alumina screws are magnetically resistant under normal conditions.

Wear resistance properties

Its super-high hardness (mohs level 9) can still maintain the original shape under continuous friction state, without being worn out, and the shape does not change.

Chemical stability of ceramic screws

Corrosion resistance

Zirconia ceramics do not react with strong acids or bases.Aging occurs at high temperatures (above 200 degrees) when water vapor is present.

Oxidation resistance

Zirconia ceramics have good properties of impermeable oxygen and liquid metals such as iron and steel.

Application range of ceramic screws:

Ceramic screw with high temperature resistance, insulation, non-magnetic, corrosion resistance, environmental protection outstanding features such as beautiful, never rust, not only can be comparable to the traditional plastic screws, metal screws, and in recent years, the performance of the ceramic screw and improved continuously, application field is becoming more and more broad, in the field of some replacement and replaced the traditional sense of the screw!

1) aerospace industry (insulation and anti-interference devices on electronic equipment)

2) electronic industry (insulation, anti-interference, light weight)

3) medical device industry (insulation, non-magnetic, environmental protection, anti-interference number, making medical machinery and equipment safer to use)

4) petrochemical industry (high temperature resistance, chemical resistance, corrosion resistance, extend the service life of equipment)

5) communication industry (insulation, non-magnetic, safety)

6) ship industry (acid, alkali and corrosion resistance, extended service life), etc

Performance and application comparison of ceramic screws with metal screws and plastic screws

Ceramic screws: the advantages of ceramic screws are high temperature resistance, wear resistance, insulation, anti-magnetic, corrosion resistance.Mechanical properties are lower than metal screws.

Metal screws: the advantages of metal screws are strong tensile strength and fracture toughness, love high temperature ability is poor, no insulation.Some metal screws have certain corrosion resistance.

Plastic screws: the advantages of plastic screws are insulation, anti-magnetic, special plastic screws with corrosion resistance.They wear out easily and are not suitable for use

The strength of the connected environment.

Classification of ceramic screws:

By material: zirconia ceramic screws, alumina ceramic screws, silicon nitride ceramic screws

According to the head shape: hexagon head ceramic screw, hexagon head ceramic screw, pan head ceramic screw, flat/countersunk head ceramic screw, etc

According to the slotting shape: cross, a word (slotting), hexagonal, rice word, plum, etc

Ceramic screw manufacturing

Of ceramic screw mainly adopts molding, already can realize large quantity of mold production, the different ways of mold production are of the same specification, the performance of the material of ceramic screw have a significant impact, some mold production of ceramic screw on the mechanical properties are close to the metal screw, and because of its special performance in many industries to replace metal screws.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730