Needle bearing, ceramic bearing clearance

Time: 2021-03-26 Writer: mingrui

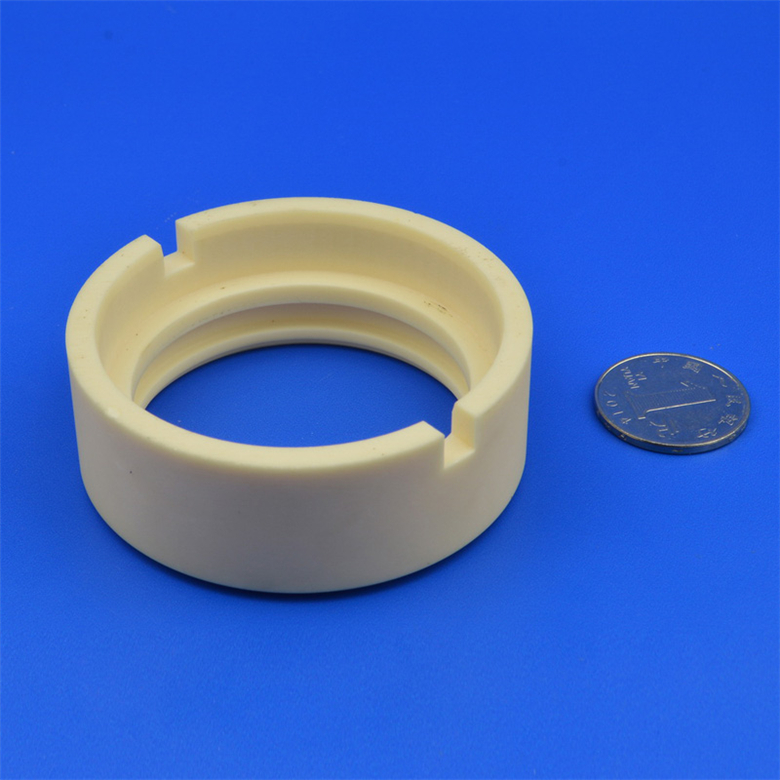

Needle bearing, ceramic bearing clearance how to choose?

The radial internal clearance of needle roller bearing varies due to the matching of the bearing, the temperature difference between the track wheel and the rolling body, the load, etc., which will have a great impact on the life, precision, sound and heat of the bearing.

If the radial clearance of needle roller bearing is too large, the vibration and sound will increase, and the radial clearance is too small, which will cause excessive pressure on the contact part between the track surface and the rolling body, causing abnormal heating and reducing the service life.

Therefore, it is ideal to give the clearance in advance before assembly, so that the clearance is zero or slightly positive when the ceramic bearing reaches a certain temperature (saturation temperature) during constant operation.

However, it is difficult to make all needle roller ceramic bearings reach this ideal state, and CM clearance is most used in general working conditions.

Needle roller ceramic bearing bearing heavy load and impact load, interference when large.C3 clearance is adopted for bearings.

Needle roller ceramic bearing bearing non - directional load, the inner and outer ring need interference.C3 bearing clearance is good.

When the inner ring temperature of needle roller ceramic bearing is higher than that of the outer ring.C3 bearings with upstream clearance.

Needle roller ceramic bearing deflection or bearing seat installation error is large.Clearance above C3

To give full play to the function of needle roller bearing, how to correctly fit the track wheel with the shaft and bearing seat is very important.The purpose of bearing fit is to keep proper interference between the bearing inner ring and shaft, outer ring and bearing seat according to the need, so as not to produce harmful sliding phenomenon.

If the interference amount of needle roller ceramic bearing is insufficient, the mating surface will produce harmful sliding in the circumferential direction, causing abnormal wear of the mating surface. The worn powder will re-enter the bearing, causing abnormal heating and vibration, etc. Therefore, appropriate mating is very necessary.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730