Ceramic bearing structure and bolt series needle roller ceramic bearing

Time: 2019-01-19 Writer: mingrui

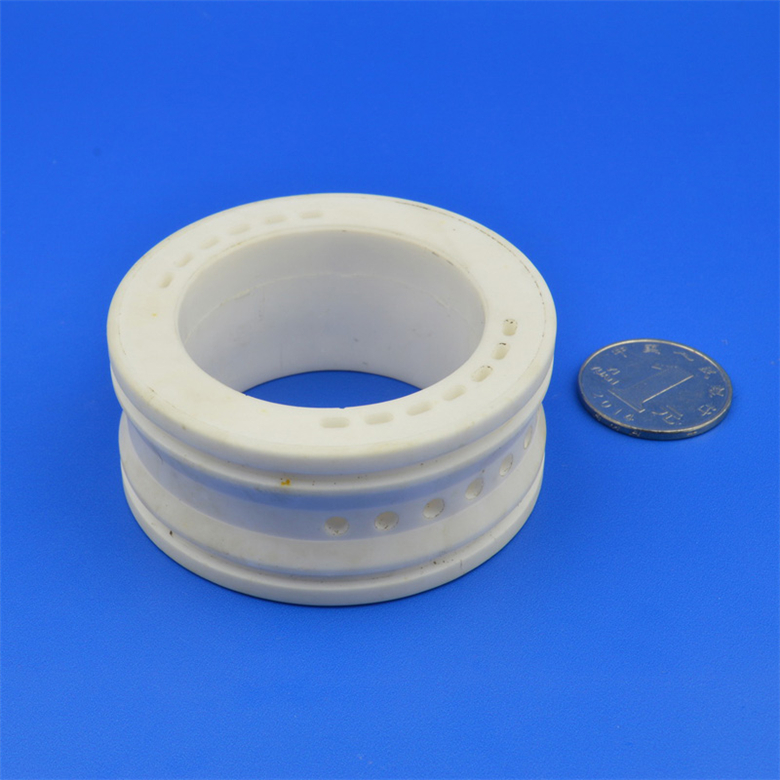

Ceramic bearing structure and bolt series needle roller ceramic bearing

CAM driven ceramic bearing as a CAM mechanism and linear motion driven bearing with high rigidity and high precision, is widely used in auto parts, exposure machine, winding machine, automatic equipment guide mechanism and automatic lock screw machine equipment.Ceramic CAM driven bearing has excellent corrosion resistance, suitable for clean room environment and high humidity environment.

Ceramic bearing, standard driven bearing is the basic type of CAM driven bearing, rod end diameter from the minimum 3mm to the maximum 30mm, the size is rich and complete, with cage, full roller, shielding, sealing, spherical outer ring, cylindrical outer ring and other types.

Ceramic bearing roller guide with cage CAM driven bearing and full roller CAM driven bearing, bearing cage is suitable for small friction coefficient high speed parts, ceramic full roller bearing is suitable for low speed rotation, bearing heavy load parts.

The structure of the seal part of the ceramic bearing is equipped with the shield type CAM driven bearing and the seal type CAM driven bearing.The sealed bearing is provided with sealing gasket in the shielded labyrinth part to prevent the invasion of foreign matters.

In order to contact with each other directly, the outer ring diameter of the CAM driven bearing is provided with spherical surface and cylindrical surface. The bearing of spherical outer ring can alleviate the unequal load caused by installation error.IKO cylindrical outer ring bearing and the other side of the track surface contact area, suitable for the load or low hardness of the track surface.

The load of the CAM driven bearing energy load, although depends on the needle roller bearing rated load, but sometimes by the rod end bending strength, shear strength and the strength of the outer ring.Therefore, the maximum static allowable load is specified.

Bearing, guide load capacity refers to the CAM driven bearing outer ring and installation side steel guide surface (plane) contact, installation side component material does not produce deformation or indentation, can continuously bear the allowable load.

The bearing slide load capacity is the value when the hardness of the component material of the opposite side is 40HRC(tensile strength is 1250N/mm2). If the hardness of the component material of the opposite side is different from that of 40HRC, the value can be obtained by multiplying it by the slide load capacity coefficient in OVO bearing technical standard.

In addition, if the lubrication between the outer ring and the opposite slide rail is not sufficient, sometimes sintering or wear may occur under certain working conditions.Especially when the ceramic bearing CAM mechanism and other high-speed rotation, need to pay attention to lubrication and surface finish.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730