: +86 18122974730

: +86 18122974730 : +86 0769-85090316-8038

: +86 0769-85090316-8038 : admin@cerampart.com

: admin@cerampart.com

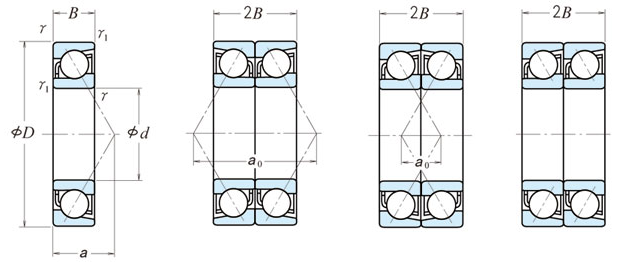

| inner diameter: d | outer diameter: D | wide: B | Basic dynamic load rating | Maximum permissible speed | Basic static load rating |

| (φ) | (φ) | (mm) | (N) | (rpm) | (N) |

| 62 | 9 | 13000 | 15000 | 8150 | - |

| 40 | 68 | 9 | 13800 | 14000 | 10200 |

| 45 | 75 | 10 | 16500 | 12000 | 10800 |

| 50 | 80 | 10 | 16800 | 11000 | 11400 |

| 55 | 90 | 11 | 20300 | 10000 | 14000 |

| 60 | 95 | 11 | 20800 | 9500 | 15000 |

| 80 | 125 | 14 | 35100 | 7000 | 31500 |

| 85 | 130 | 14 | 35800 | 6700 | 33500 |

| 100 | 150 | 16 | 46200 | 5600 | 44000 |

| 110 | 170 | 19 | 60500 | 5000 | 57000 |

| 12 | 32 | 14 | 10600 | 20000 | 6200 |

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

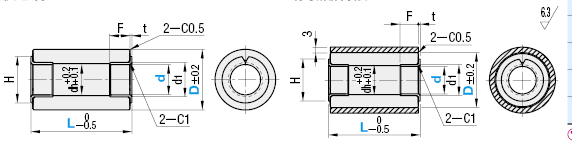

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve