Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Zirconium dioxide (chemical formula: ZrO2) is the main oxide of zirconium, usually as a white odorless, tasteless crystal, insoluble in water, hydrochloric acid and dilute sulfuric acid.It usually contains a small amount of hafnium dioxide.Chemically inactive, high melting point, high resistivity, high refractive index and low coefficient of thermal expansion make it an important high temperature resistant material, ceramic insulation material and ceramic sunscreens, and is also the main raw material for manual drilling, energy band gap is about 5-7eV.Used for making metal zirconium and zirconium compounds, making refractory bricks and crucible, high frequency ceramics, grinding materials, ceramic pigments and zirconates, etc.

The definition of zirconium dioxide is based on material science. It refers to a crystal with thousands or tens of thousands of cells juxtosing each grain, which repeats only a few dozen cycles in the direction of a crystal axis.Of course, this explanation is in some of the tongue, but the characteristics of microcrystalline ceramics is good, with high thermal conductivity and thermal expansion coefficient close to zero, not water absorption, good insulation performance, compact uniform structure, impact resistance, wear resistance and corrosion resistance and other excellent properties.Simply put, it is resistant to fall, wear resistance, does not affect heat dissipation and beauty.

As far as we know, zirconia ceramics (raw materials: non-metallic minerals) are abrasion resistant, high temperature resistant and non-conductive.However, if the piezoelectric zirconia ceramic rod is not used properly under high temperature and high pressure, it will bring certain damage to the ceramic rod.Myon teaches everyone how to properly use a piezoelectric zirconia ceramic rod.

After the piezoelectric zirconia ceramic rod is heated in the air, the dense zirconia film forms on its surface, which becomes the anti-oxidation (anti-oxidation free radical) protective film, and plays the role of prolonging its service life.

Ceramic production of zirconia requires the preparation of powders with high purity, good dispersion, ultrafine particles and narrow particle size distribution.Zirconia method There are many methods for preparing ultrafine powders.The purification of zirconia mainly includes chlorination and thermal decomposition, alkaline metal oxidation decomposition, lime melting, plasma arc, precipitation, colloid, hydrolysis, and spray pyrolysis.Air jet loom auxiliary nozzle repairman needs to carry out daily maintenance on electric oil pump, central oil supply, heat dissipation part of main motor, input shaft of open CAM box, electromagnetic brake, weft finder, scissors, edge grinding, side brace and yarn grab.

The higher the current flow rate applied to the ceramic rod, the higher the surface temperature of the ceramic rod.Blue zirconia ceramics (raw material: non-metallic minerals) service life is short, the service temperature is higher, so after the furnace temperature exceeds 1600℃, the oxidation speed is accelerated, the service life is shortened.When using, we should pay attention not to make the surface temperature of the ceramic rod too high.

During use, the resistance gradually increases due to the oxidation of the rod.In order to keep the furnace temperature normal, the applied voltage should be increased.When the voltage rises to the maximum limit of the transformer (pressure variable), it still cannot meet the requirements. Therefore, before continuing to use, the furnace should be stopped and the connecting rod should be changed.

When the new furnace starts to supply power, the voltage should be increased gradually to prevent rod breaking.Generally speaking, it is best to start at 1/2 of the rated voltage and gradually increase the voltage as everything is normal.New or electric furnaces that are not used for a long time must be baked before use.When baking, use an old rod or other heat source whenever possible.

The fine ceramic rod is strictly prohibited to be overloaded.If it is found that the rod is broken for some reason or heated unevenly, and the local part is incandescent or dark red, it indicates that the rod aging is inconsistent and the resistance of each section is too different, so the furnace should be stopped for repair and replacement.Keep away from moisture when storing.The production of zirconia ceramics requires the preparation of powders with high purity, good dispersion, ultrafine particles and narrow particle size distribution.Zirconia method There are many methods for preparing ultrafine powders.The purification of zirconia mainly includes chlorination and thermal decomposition, alkaline metal oxidation decomposition, lime melting, plasma arc, precipitation, colloid, hydrolysis, and spray pyrolysis.If it is found that the aluminum sprayed part of the rod end has deteriorated and deliquated, it can be sprayed again after surface treatment.If no aluminum spray condition is available, several layers of aluminum foil can be wrapped around the aluminum spray section for reuse.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

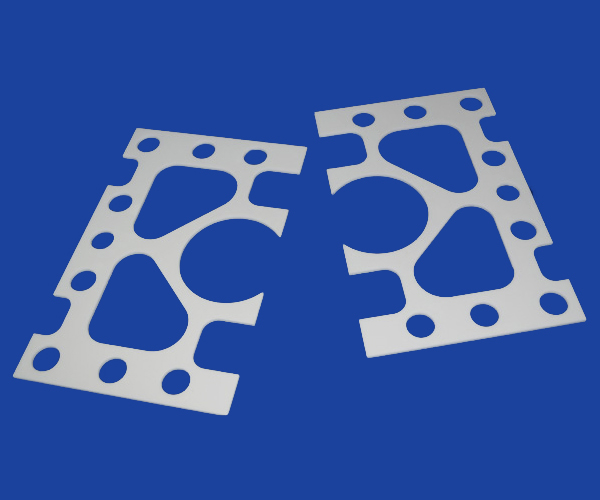

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS