Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

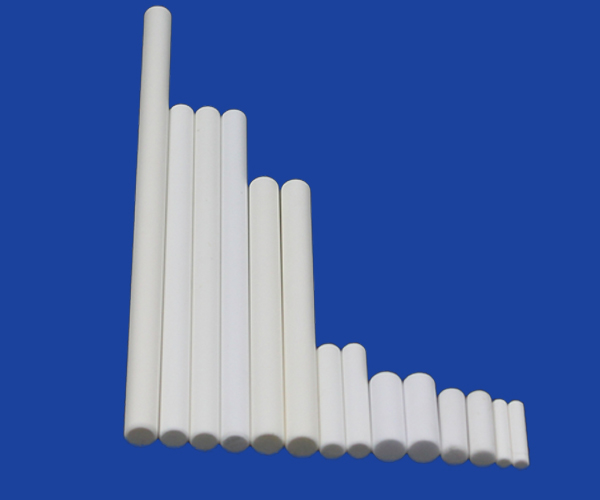

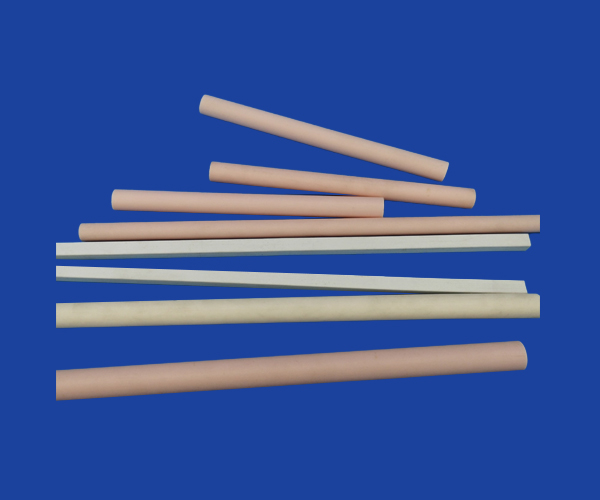

Zirconia ceramic ZrO2 rod has different functions, Zirconia ceramic rods have the advantages of super hardness, high wear-resisting, good corrosion resistance, high temperature tolerance, high strength, high mechanical strength, good chemical stability, polishing surface and so on.

Zirconia rods and tubes are used in shaft, plunger, sealing structure, automobile industry, oil drilling equipment, Insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity.

| Properties | Unit | CeramaZirc | CeramaZirc Plus | CeramaZirc Nano-HIP |

| Composition | Yttria Stabilized | Yttria Stabilized | Yttria Stabilized | |

| Color | Ivory | Ivory | Grey | |

| Mechanical | ||||

| Density | g/cm3 | 6.05 | 6.05 | 6.07 |

| Youngs Modulus | GPa | 200 | 200 | 200 |

| Fracture toughness | Mpa x m^1/2 | 8 | 8 | 8 |

| Poissons Ratio | 0.30 | 0.30 | 0.30 | |

| Compressive Strength | MPa | 2100 | 2100 | 2100 |

| Flexural Strength | MPa | 850 | 1200 | 1400 |

| Hardness (Vickers 500g) | GPa | 12.5 | 13.5 | 14.5 |

| Thermal | ||||

| Max Use Temp * | °C | 1000 | 1000 | 1000 |

| Coefficient of Expansion | 10^-6/°C | 10 | 10 | 10 |

| Thermal Conductivity, 25°C | W/mK | 2 | 2 | 2 |

| Thermal Shock Resistance ΔT | °C | 250 | 250 | 250 |

| Electrical | ||||

| Dielectric Strength 6.35mm | ac-kV/mm | 9.0 | 9.0 | 9.0 |

| Dielectric Constant 25° C | 1 MHz | 29 | 29 | 29 |

| Volume Resistivity | ||||

| 25°C | Ω cm | >1 x 10^13 | >1 x 10^13 | >1 x 10^13 |

| 300°C | Ω cm | 1 x 10^10 | 1 x 10^10 | 1 x 10^10 |

| 500°C | Ω cm | 1 x 10^6 | 1 x 10^6 | 1 x 10^6 |

| 700°C | Ω cm | 5 x 10 ^3 | 5 x 10 ^3 | 5 x 10 ^3 |

|

|

|

General Zirconia Properties

Tolerance control : OD best to be 0.005mm, overall length to be 0.01mm Roughness Ra0.2 Cosmetic quality: Smooth surface without no comtamination, deformation and crack |

User industries Automotive, aviation, space travel Electrical and thermal insulation Electronics and sensors Energy technology, power generation Environmental technology Fluid technology Friction-reduction, wear- and corrosion -protection High temperature applications Laboratory technology Laser technology Mechanical and chemical process engineering Metal industry Optics Semiconductor processing equipment Surface treatment Vacuum technology Other industries |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS