Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730Part of sizes for us produce zirconia platelike below

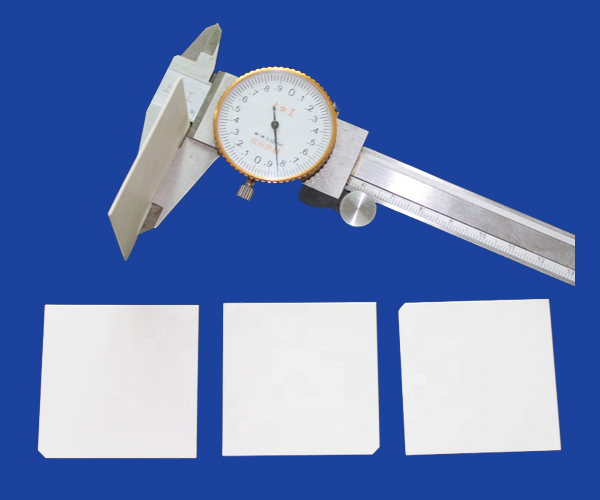

| Item | Unit | zirconia plate | |

| Dimension | inch(max) | 5.5"×7.5" | 5.7"×7.8" |

| Tolerance |

±1% NLT:±0.1㎜ |

±1.5% NLT:±0.1㎜ |

|

| Thickness | ㎜ | 0.25~1.0 | 0.25~1.0 |

| Tolerance |

±10% NLT:±0.04㎜ |

±10% NLT:±0.04㎜ |

|

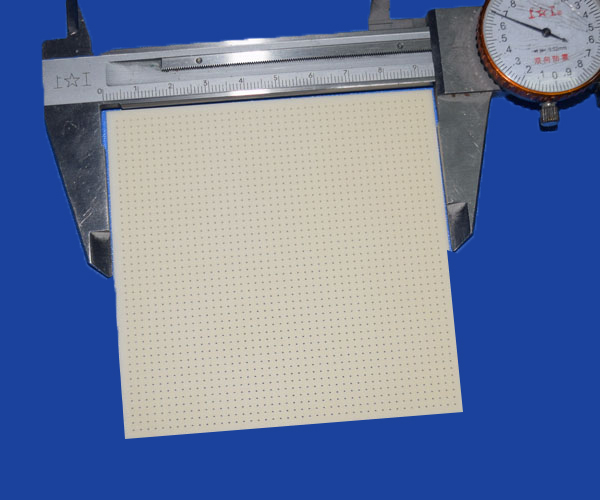

| Through hole | ㎜ | Φ0.2~ | Φ0.2~ |

| Tolerance |

±0.6% NLT:±0.05㎜ |

±0.6% NLT:±0.05㎜ |

|

| Warpage | ㎜ | 0.005/㎜ | 0.005/㎜ |

|

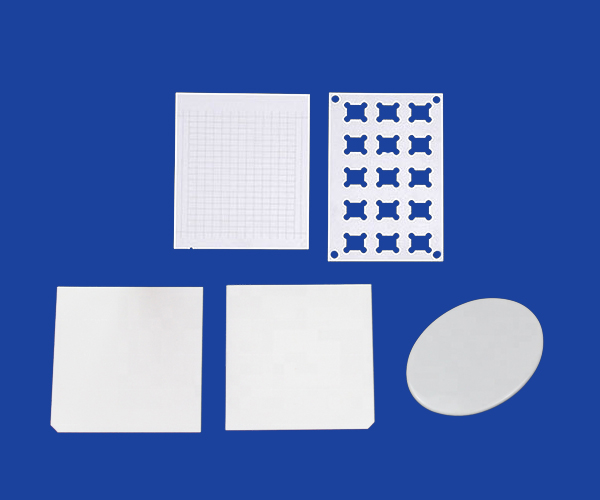

For other sizes of the zirconia plate please contact us.thanks and for custom ,please send a details or files to our official e-mail: admin@cerampart.com thanks The shape types of the zirconia plate round, oval, square, irregular, etc According to the customer requirement or the drawing. The main materials of the zirconia ceramic plate: · TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2) |

|

Features of the zirconia plate

Good smoothness / flatness with less porosity. Excellent in adhesion with thin film and thick film materials.

Less variance in outline, plate thickness, slit pitch, etc.

Minimal warpage, bending, and undulation.

Physical and chemical properties are stable even under a hot environment. Excellent in thermal shock resistance. High thermal conductivity and coefficient of thermal expansion similar to that of silicon.

Superior mechanical strength. Products with higher mechanical strength are also in our lineup.

Excellent resistance against oil and chemical.

Excellent in insulation properties, high dielectric breakdown voltage, high surface resistivity / volume resistivity, and small dielectric constant.

Stable breaking strength, and less variance in shape or dimensions.

The high reflective substrate, especially suitable for optical applications such as LED, is also available.

| Properties | Unit | CeramaZirc | CeramaZirc Plus | CeramaZirc Nano-HIP |

| Composition | Yttria Stabilized | Yttria Stabilized | Yttria Stabilized | |

| Color | Ivory | Ivory | Grey | |

| Mechanical | ||||

| Density | g/cm3 | 6.05 | 6.05 | 6.07 |

| Youngs Modulus | GPa | 200 | 200 | 200 |

| Fracture toughness | Mpa x m^1/2 | 8 | 8 | 8 |

| Poissons Ratio | 0.30 | 0.30 | 0.30 | |

| Compressive Strength | MPa | 2100 | 2100 | 2100 |

| Flexural Strength | MPa | 850 | 1200 | 1400 |

| Hardness (Vickers 500g) | GPa | 12.5 | 13.5 | 14.5 |

| Thermal | ||||

| Max Use Temp * | °C | 1000 | 1000 | 1000 |

| Coefficient of Expansion | 10^-6/°C | 10 | 10 | 10 |

| Thermal Conductivity, 25°C | W/mK | 2 | 2 | 2 |

| Thermal Shock Resistance ΔT | °C | 250 | 250 | 250 |

| Electrical | ||||

| Dielectric Strength 6.35mm | ac-kV/mm | 9.0 | 9.0 | 9.0 |

| Dielectric Constant 25° C | 1 MHz | 29 | 29 | 29 |

| Volume Resistivity | ||||

| 25°C | Ω cm | >1 x 10^13 | >1 x 10^13 | >1 x 10^13 |

| 300°C | Ω cm | 1 x 10^10 | 1 x 10^10 | 1 x 10^10 |

| 500°C | Ω cm | 1 x 10^6 | 1 x 10^6 | 1 x 10^6 |

| 700°C | Ω cm | 5 x 10 ^3 | 5 x 10 ^3 | 5 x 10 ^3 |

Applications of the zirconia plate

Heat dissipation substrate for automotive, sustainable energy and LED package application and other industry

Other type of ceramic sheet/ plate/ substrate/ piece/ blank

· Ttz: Magnesia Partially Stabilized Zirconia (Zro2) Sheet/ Plate/

· Ytzp: Yttria Partially Stabilized Zirconia (Zro2) Sheet/ Plate/

· Zdy: Yttria Fully Stabilized Zirconia (Zro2) Sheet/ Plate/

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS