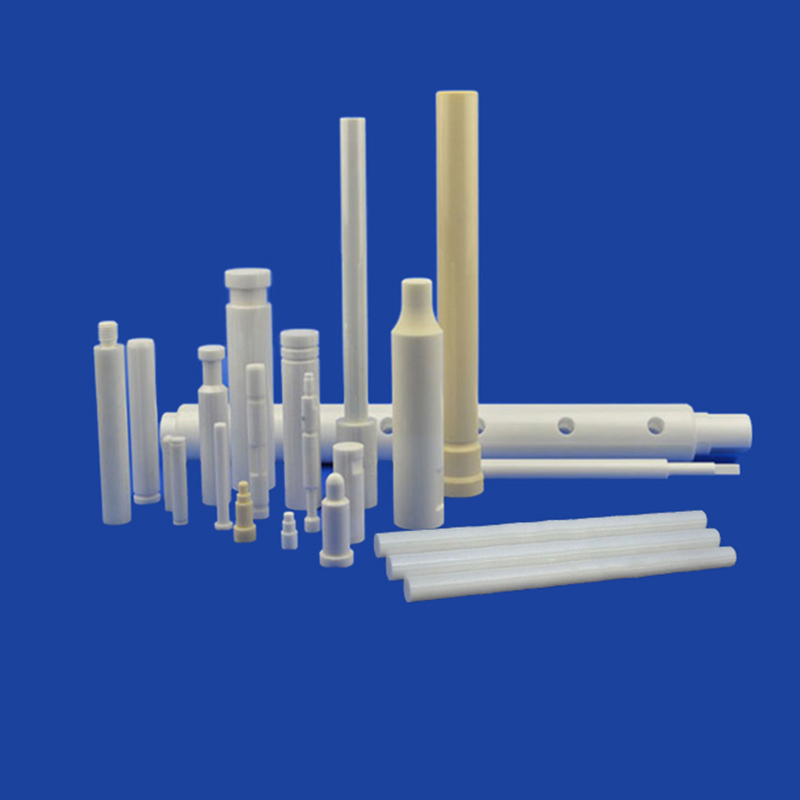

As we all know, the role of positioning pins is to limit the free movement of objects. Compared with traditional material positioning pins, the ceramic positioning pins produced by the advanced ceramic materials used by Mingrui Ceramics Factory have greater advantages, such as zirconia ceramic positioning pins, alumina ceramic positioning pins, and silicon nitride positioning pins.

There are 5 types of positioning pins:

1. Fixed positioning pin

2. Replaceable positioning pins

3. Cone locating pin

4. Edge-cut positioning pin

5. Standard diamond positioning pin

The function of the positioning pin is to limit the free movement of the article. Degrees of freedom: Any object in space must have six degrees of freedom, X Y Z linear motion in three axial directions, and rotational motion around X Y Z. Locating pins are parts that participate in restricting these degrees of freedom. In a mold composed of two or more parts, a pin designed to accurately position two adjacent parts of the mold. In the spindle positioning, first 1) mechanical cam mechanism (2) the photoelectric disk method for rough positioning, and then a hydraulic or pneumatic positioning pin is inserted into the pin hole or pin groove on the spindle to achieve precise positioning. After the tool change is completed, the positioning pin exits , The spindle starts to rotate.

Ceramic positioning pins have strong corrosion resistance, and can also be used in strong acids, strong alkalis, and seawater. At 1100°C, the strength and hardness are almost unchanged. It can also be used in non-magnetic and magnetic fields. Electrical insulation. The density is 3.25--3.28g/cm3, and the weight is light, about 60% lighter than steel balls, which greatly reduces the centrifugal force on the channel when the bearing rotates at high speed and reduces wear. High rigidity, high strength, its hardness is twice higher than that of bearing steel, and its elastic modulus is about 1/3 higher. The coefficient of linear expansion is 3.2×10-6/K, which is almost 1/4 of the bearing steel, and it can withstand rapid changes in temperature.

(1) Performance characteristics:

1. Ceramic positioning pins are similar to common welding positioning pins, except that they are made of super-hard silicon nitride ceramic material. The special physical and chemical properties of ceramic materials determine some special properties of silicon nitride positioning pins. For example, high wear resistance, high hardness, non-conductivity, non-magnetic, non-sticking welding slag and other excellent properties.

2. Below I will briefly introduce the performance of ceramic materials:

High hardness: the hardness of zirconia is second only to diamond

High wear resistance: high hardness and good red hardness determine the excellent wear resistance of zirconia positioning pins

Cost-effective: The service life of zirconia positioning pins is ten times that of ordinary positioning pins

(2) Application areas:

Ceramic materials such as zirconia and silicon nitride are wear-resistant at high temperature and are used as mechanical parts, used as rotors, stators, etc. in engines; hot-pressed pistons, reaction sintering burners, spark plugs, cylinder liners and other precision parts; heat resistance Good vibration resistance, used as thermowells, ceramic positioning pins, molds, crucibles, furnaces, burners, heating element fixtures, furnace linings, aluminum liquid conduits, valves, etc.; good corrosion resistance, used as ball valves and seals in chemical industry Rings, filters, heat exchanger components, etc.; good wear resistance, used as bearing balls, rollers, seat rings, high temperature bolts, plunger pumps, sealing materials, etc. in the machinery industry; used in electronics, military and nuclear industries For circuit substrates, film capacitors, high-temperature insulators, radomes, spacers, etc.

Mingrui Ceramics can customize various non-standard shaped ceramic positioning pins and special-purpose shaped ceramic positioning pins according to the customer's use environment, use requirements and required material properties.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730