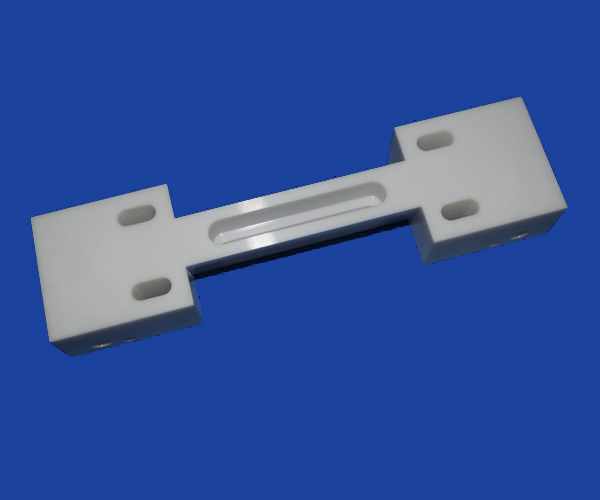

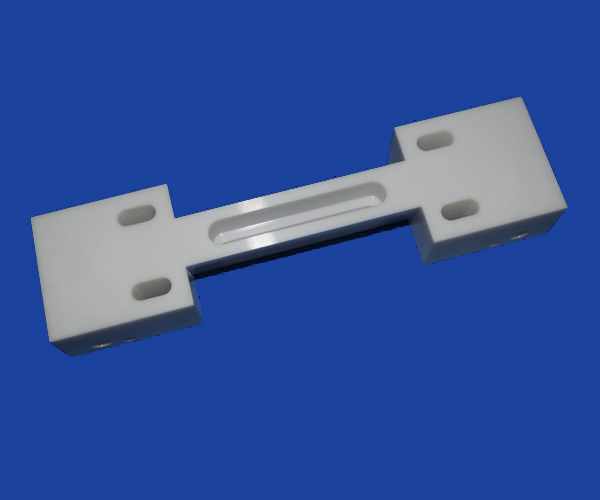

Ceramic machining parts with very high precision

In the mechanical processing industry, precision Ceramic machining parts processing is exponential control mechanical processing, will need to be processed drawings programming, and then the computer is connected to the Ceramic machining parts machining machine tool, through the computer program to command the operation of Ceramic machining parts machining machine tool, so as to complete precision parts processing.Precision Ceramic machining parts processing is mainly suitable for large quantities, small quantities of many kinds of spare parts processing, Ceramic machining parts precision is very high.

First of all, we need to know the shape, position and size of the workpiece before precision Ceramic machining parts machining.Measure whether the size of billet conforms to the requirement of drawing.

Ceramic machining parts machining process after the completion of rough machining self-check, error data can be adjusted in time.The main content of self-inspection is the size of the position of the processing part.

(1)Ceramic machining parts processing technology collision number starting point is correct;

2) The dimensions from the machining parts of Ceramic machining parts to the reference point do not meet the requirements of the drawings;

V (3) mechanical parts are not loose in the process of processing;

4) the location and size of Ceramic machining parts.

Ceramic machining parts shall be finished after rough machining confirmation. Self-inspection of the parts shall be completed, and the workpiece shall be removed and sent to the inspector for special inspection after confirming that the parts are in accordance with the drawings and process requirements.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730