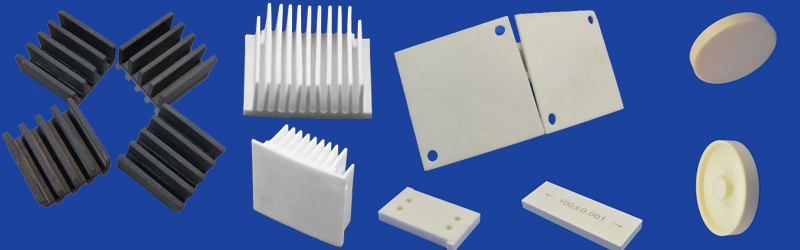

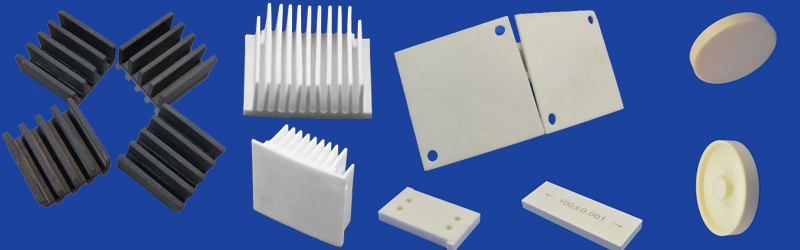

Ceramic Heat Sink For Electronic Components

Ceramic heat sink is a kind of device which can dissipate heat easily for electronic components in electric appliances.

Among many electronic products, the metal fin is a kind of heat dissipation device of IC chip of electronic equipment. The metal fin increases the area of convection with air, and the fan increases the velocity of air circulation, which can accelerate the heat diffusion of electronic components.Today, as electronics move toward high-power miniaturization, there is less room for metallic fins.Now in the electronic industry began to use ceramic heat sink to replace the metal heat sink.

Advantages of ceramic heat sink:

1, ceramic heat capacity is small, itself does not store heat, direct heat dissipation, not like metal heat sink like the formation of "heat ladder", affect heat dissipation;

2, the biggest characteristic, is the ceramic itself micro hole structure, greatly increase the contact with the air of the cooling area, greatly enhance the cooling effect, compared to the same conditions, in the condition of natural convection, heat dissipation effect than super copper, aluminum, airtight environment, active radiation cooling capacity 8.8 times and metal materials, heat dissipation advantages more apparent.

3, ceramic insulation, high temperature resistance, oxidation resistance, acid and alkali resistance, cold and heat shock resistance, low thermal expansion coefficient, to ensure the stability of ceramic heat sink in high and low temperature environment or other harsh environment;

4, ceramic can withstand large current, can play high voltage, can prevent leakage breakdown, no noise, will not produce coupling with MOS power tube parasitic capacitance, and therefore simplify the filtering process;The required creepage distance is shorter than that required by metal body, which further saves plate space and is more conducive to the design of engineers and the passing of electrical certification.

5, ceramics can effectively prevent interference, anti-static effect, and moisture absorption, dust, does not affect the effect;

6, ceramic small size, light weight, do not take up space, save materials, save freight, more conducive to the rational layout of product design;

7, ceramics belong to inorganic materials, more in line with environmental protection;

Ceramic heat sink are mainly composed of silicon carbide ceramics, SIC ceramic itself is not a kind of regenerative ceramic microporous structure, with excellent electrical insulation properties, compared with the same area of the metal heat sink to 30% more and air contact area, and in the case of natural convection and radiation heat dissipation performance is more than 8 times of metal, and won't cause interference phenomenon to the peripheral electronic components.

In the electronic industry, ceramic chips are widely used in the heat dissipation of electronic products with high space requirements, such as: network set-top box, smart speaker, security camera, router, small projector, ultra-thin display, etc. Common ceramic heat dissipation chips have three forms: flat plate, wave and groove.

Specifications

Installation of ceramic heat sink practical application.In fact, different devices and different environments have different requirements for ceramic heat sinks, in addition to the basic performance requirements for ceramic heat sinks.For example, some routers require that the specifications of ceramic heat sinks include ring, square, etc., but a certain number of screw holes and grooves, etc..

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730