Ceramic substrate for the lighting industry

The LED lamp is a semiconductor chip that is converted into light by electric energy. It is fixed on the bracket with silver glue or white glue. Then the chip and the circuit board are connected by silver wire or gold wire, and the periphery is sealed with epoxy resin to protect the inner core wire.

The role of the final installation of the lamp housing. LEDs can develop rapidly in the lighting market and have a lot to do with their own advantages. The LED lamp adopts the most advanced secondary light distribution technology and imported packaging technology, and has many advantages: the bulb is small in size, light in weight, and energy-efficient.

It consumes only a few kilowatts in a thousand hours, while the general 60W incandescent lamp is ten. It takes 1 kWh in seven hours. The ordinary 10W energy-saving lamp consumes 1 kWh in one hour, and the LED lamp has a long life. The lamp is not afraid of vibration and is not easy to be broken. Under normal conditions, the service life can reach 50,000 hours. The life of ordinary incandescent lamps is 50 times longer than that of ordinary energy-saving lamps. In addition, LED lamps have green functions.

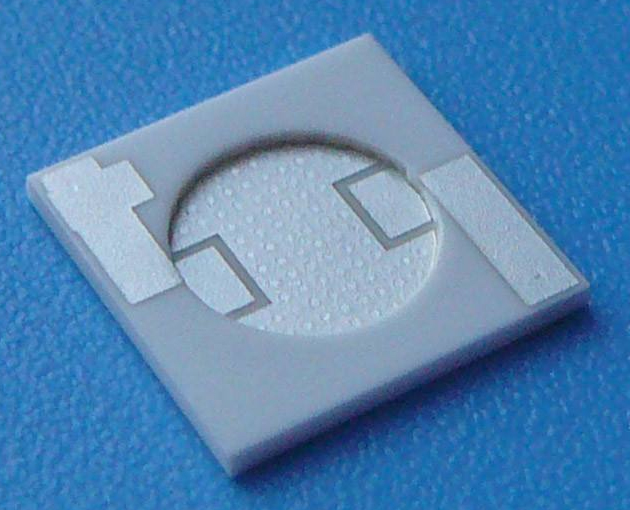

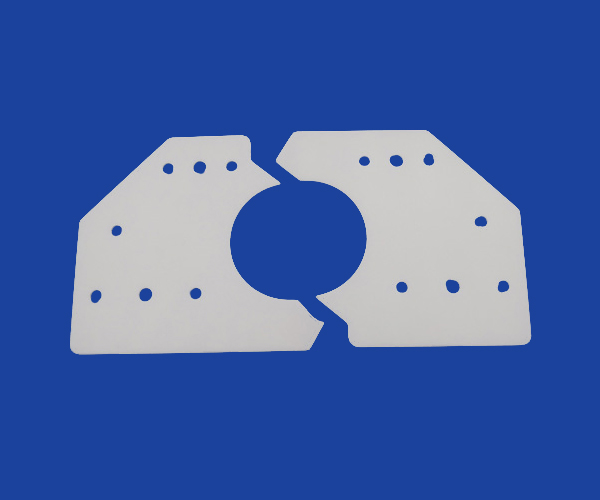

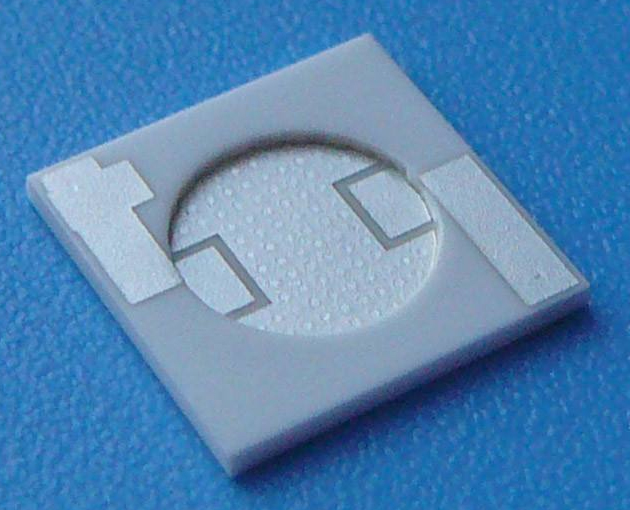

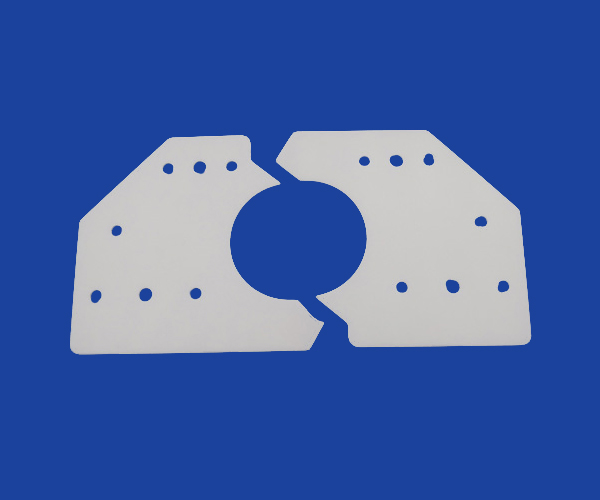

Ceramic circuit boards are widely application, and the most representative ones are the use of LED lights.

Everyone knows that the lights are illuminated by electricity. According to statistics, only 20% of electricity will be converted into light, and the rest will be converted into heat. If there is no way to dissipate heat in time, the temperature inside the lamp will be too high, which will greatly shorten the life of LED. This is also restricting the development of LED lamp industry. Problems to be solved.

The use of ceramic circuit boards effectively solves the heat dissipation problem of LED lamps.

The ceramic substrate has good thermal conductivity: the thermal conductivity of the conventional aluminum-based circuit board MCPCB is 1 to 2 w/mk, and the thermal conductivity of the copper itself is 383.8 w/mk, but the thermal conductivity of the insulating layer is only about 1.0 w/mk. A little better can reach 1.8w/mk, the thermal conductivity of the alumina ceramic substrate is 15 ~ 35 w / mk, the thermal conductivity of the aluminum nitride ceramic substrate is 170 ~ 230 w / mk, the thermal conductivity of the copper substrate 2w / Mk; aluminum/copper-based circuit board itself has high thermal conductivity of aluminum, but there is an insulating layer on the aluminum/copper-based circuit board, resulting in a decrease in thermal conductivity of the entire board.

The ceramic circuit board uses inorganic non-conductive ceramic as the substrate, and then the metal directly contacts the ceramic, and the generated heat is quickly transferred to the substrate. Thus, the heat generated by the LED lamp during the illumination process can be quickly dissipated through the circuit board material behind, reducing Damage to ensure better life.

The development of LED lights is the second revolution since the development of incandescent lighting, and ceramic circuit boards have been tried in various lighting devices. The development of LEDs will accelerate the promotion of ceramic circuit boards. At present, the commercial giants in the major lighting industries have been using ceramic circuit boards in a drastic reform.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730