Wear Resistant Ceramic Parts For Industry Applications

Materials of wear resistance ceramic parts

Aluminium oxide RAPAL more information...

Zirconia M and Zirconia Y more information...

Zirconia toughened alumina more information...

Silicon nitride

Classification and characteristics of wear resistance ceramics

1.Definition and performance characteristics of wear-resistant ceramics

Definition of wear-resistant ceramics:

Wear resistance ceramics are mainly made of ceramics with rare metal oxides as flux 1700 ℃ high temperature roasting of special alumina ceramic, with special rubber and high strength Degree of organic/inorganic adhesive combination of products.

Wear resistance ceramic performance characteristics:

1. The hardness

Its hardness is hra80-90, the hardness is second only to diamond, far more than the wear resistance of steel and stainless steel.

2. Excellent wear resistance

Its wear resistance is equivalent to manganese steel 266 times, high chromium cast iron 171.5 times.Under the same working condition, the service life of the equipment can be extended by at least 10 times.

3. Light weight

Its density is 3.6-3.9g/cm3, only half of the steel, which can greatly reduce the load of equipment.

4. Good adhesion and heat resistance

5. Wide application of wear resistance ceramics

The coal transportation system, material transportation system, powder making system, ash discharge system, dust removal system and other machinery and equipment with large wear and tear of enterprises such as thermal power plant, iron and steel, smelting, machinery, coal, mining, chemical industry, cement, port and wharf can choose different types of products according to different needs.

Main technical indicators of wear resistant ceramics

Main technical indicators of wear resistant ceramics:

Alumina content ≥95%

Density ≥3.5 g/cm3

Rockwell Hardness ≥80 HRA

Compressive strength ≥850 Mpa

Fracture toughness KΙC≥4.8MPA?M1/2

Flexural Strength ≥290MPa

Heat conduction coefficient 20W/m.K

Coefficient of thermal expansion: 7.2X10-6M/M.K

Adhesive type and impact resistance type wear resistant ceramic lining rubber main performance indicators:

Breaking Strength (MPA) ≥12

RIP extension (%) ≥250

Shaw hardness (degrees) 55-65

Disconnect permanent deformation (%) ≤24

Bonding Force (MPA) (shear stress) of rubber and ceramics ≥3.0

Temperature resistant ≤100℃

Rubber aging years ≥ 15

The main performance index of rubber for heat-resistant adhesive wear resistant ceramic lining Plate:

Breaking Strength (MPA) ≥7.5

RIP extension (%) ≥300

Shaw hardness (degrees) 48-58

Disconnect permanent deformation (%) ≤16

Bonding Force (MPA) (shear stress) of rubber and ceramics ≥3.0

Temperature resistant ≤250℃

Rubber aging years ≥ 15

Main performance index of rubber for hardy adhesive wear resistant ceramic lining Plate:

Project name Metrics

Breaking Strength (MPA) ≥12

RIP extension (%) ≥350

Shaw hardness (degrees) 48-58

Disconnect permanent deformation (%) ≤24

Bonding Force (MPA) (shear stress) of rubber and ceramics ≥3.0

Temperature resistant ≥-50℃ Rubber aging years ≥ 15

Classification of wear resistant ceramics

wear resistance ceramic pipe fittings and ceramic valve series

(1)Wear resistant ceramic pipe fitting application scope:

A. Power plant boiler powder system pipeline, including, powder transport pipeline, thick and thin powder separator pipeline, coal fall pipe, combustion system of the primary air pipeline, secondary air pipeline, three times pipeline and burner pipeline, in addition to the ash and slag discharge system of the slag discharge pipeline, back powder pipeline, dry ash transport pipeline;

B. Steel plant raw material conveying pipe, receiving pipe, dust removal pipe, ash discharging pipe, ash falling pipe, mixing pipe, grinding export pipe, coal burning pipe, pulverized coal pipe, separator pipe, burner radius pipe and other wear elbow pipe;

C. Cement plant sorting machine outlet pipe, sorting machine inlet pipe, dust collection pipe, vertical grinding out air pipe, circulating air pipe, coal mill high temperature fan air pipe, feeding pipe and other wear elbow pipe;

D. All kinds of pipe fittings for processing and conveying materials such as petroleum, chemical industry, mining, coal, coal washing plant, smelting, papermaking, aluminum industry, building materials, powder engineering, grain machinery, etc.

Wear resistant Ceramic valve is the use of ceramic wear resistance, corrosion resistance production wear resistant parts instead of metal material valve.

wear resistant Ceramic ball valve, wear resistant ceramic gate valve, wear resistant ceramic regulating valve, wear resistant ceramic globe valve, wear resistant ceramic check valve and other valve products are high-tech wear resistant ceramic sealing parts, which have been widely used in thermal power generation, petroleum, chemical, mining, metallurgy and other fields.

Wear resistant Ceramic valve features:

A. wear resistant Ceramic valve adopts high-tech new ceramic structural materials to make the sealing parts and vulnerable parts of the valve, which improves the wear resistance, corrosion resistance and sealing of the valve products and greatly extends the service life of the valve.

B. The use of wear resistant ceramic valves can greatly reduce the number of valve maintenance and replacement, improve the safety and stability of the supporting equipment operating system, reduce the labor intensity of workers, and save equipment repair costs

C. The use of wear resistant ceramic valves can improve the sealing of industrial piping system, and at the same time can minimize leakage, will play a positive role in promoting environmental protection.

D. wear resistant Ceramics are made from a wide range of raw materials with low cost. Ordinary elements such as aluminum, carbon and silicon can be used to produce ceramic materials with superior performance, which can save a lot of metal materials and rare mineral resources.

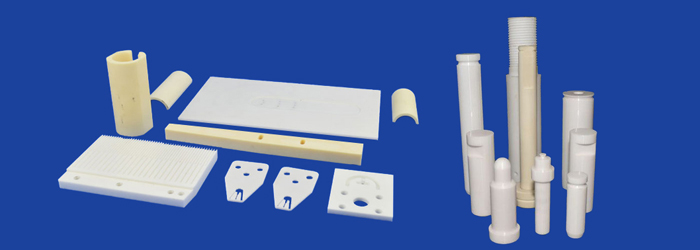

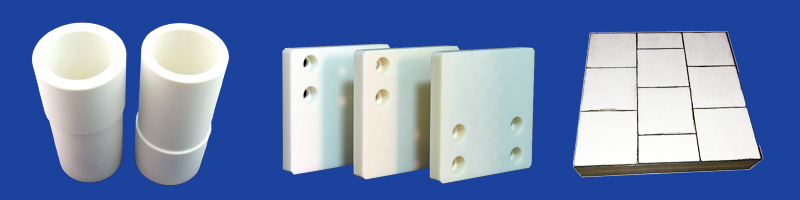

(2) wear resistance ceramic liner series

wear resistance ceramic liner primarily used to transport a variety of all kinds of high hardness and high abradability of particulate matter quality equipment, including electric power, heat, steel, coal, cement, mining, smelting, petroleum, building materials, chemical, fan, paper making, machinery, powder engineering, food, tobacco and other industries of all kinds of coal, transporting system, pulverizing system, ash discharge and dust removal system and other mechanical equipment.

wear resistant ceramic can be used on the inner surface of static parts, such as pipes, elbows, separators, chutes, valves, various shells, etc., according to the way of combination with metal matrix, and also on high-speed rotating equipment, such as various fan rotors, impellers, rollers, etc.Pulverizing system of thermal power plant, coal mill outlet pipe, coarse and fine powder separator, primary air pipe elbow, induced draft fan, inner shell of pulverizer, air pretreatment, Heater, tail flue, medium speed grinding cone bucket and other equipment;Dust removal system of steel works and smelter, wind pipe elbow and inner shell of dust remover, etc.

(3) wear resistant ceramic ball, wear-resistant ceramic bar and wear resistant ceramic microbeads

wear-resistant ceramic ball, wear-resistant ceramic bar products with high hardness, high density, low wear, good regularity, corrosion resistance and other characteristics. wear resistant ceramic is used as grinding medium in ball mill, vibration mill, planet mill and stirring mill in ceramic, cement, coating, enamel, pigment, chemical industry, refractory material, food, inorganic mineral powder and other industries.

Wear resistant ceramic ball, wear resistant ceramic rods can shorten the grinding time, improve the grinding efficiency, the benefit from alumina itself excellent material properties, compared with the traditional grinding media, high hardness and than major, in the same grinding materials by grinding load increasing, ballstone density, specifications, ball grinding collision probability increases with material.Due to its high wear resistance, the stability of the chemical composition of the grinding materials is largely guaranteed.

wear resistant Ceramic microbeads are a kind of non-metallic multi-functional material, the main components are SiO2 and Al2O3, the diameter between 5-10 microns, appearance is white, loose, high sphericity, good mobility, high whiteness, high melting point.

The application of wear resistant ceramic microbeads in plastics has the following characteristics:

A. good fluidity and stable product size: wear resistant ceramic microbeads have excellent flow performance, which can improve production efficiency, reduce energy consumption, improve product size stability and prevent warping.

B. Improve appearance and eliminate fiberglass exposure: the fiberglass modification for various engineering plastics can eliminate the phenomenon of fiberglass exposure, improve the flow performance, reduce the amount of fiberglass and reduce the cost.

C. Good thermal stability, flame retardant: wear resistant ceramic microbeads high melting point, high temperature does not decompose, can improve the flame retardant products and thermal deformation temperature.

D. Good insulation and low water absorption: wear resistant ceramic microbeads with high specific resistance and low water absorption (0.2%) are used in the production of cable insulation materials.

E. Strong corrosion resistance: wear resistant ceramic microbeads are mainly composed of aluminum silicate, which can keep stable in various organic solutions, acid and alkali solvents.

Wear resistant Ceramic microbeads (recommended for classification in the category of corrosion resistant industrial ceramics) are mainly used for the following types of adhesive products:

A. The modification of A nylon, PP, PBT, PC, POM and other engineering plastics can improve the fluidity, eliminate the glass fiber exposure, overcome warping, improve the flame retardant performance, reduce the amount of glass fiber and reduce the production cost.

B. Fill hard PVC, PP, PE, production profile, pipe and plate, can make the products have good size stability, improve the rigidity and heat resistance temperature, improve products cost performance, improve production efficiency, reduce costs.

C. Wear resistant ceramic microbeads is filled in PVC, PE and other cables, insulation sheath material, can improve the product's high temperature resistance, insulation, acid and alkali resistance and product processing performance, improve the output, reduce the cost.

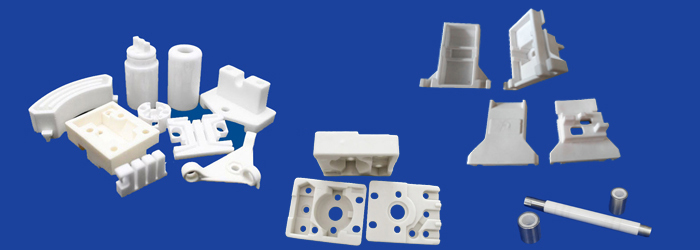

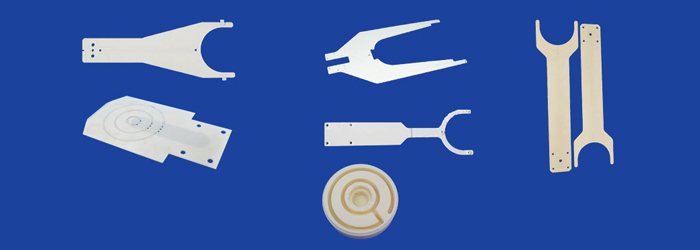

(4) Wear resistance ceramic tools and other wear resistant ceramic shaped parts

A. Wear resistance Ceramic cutting tools have alumina (Al2O3) base and silicon nitride (Si3N4) base two categories, with high efficiency, long service life and good processing quality and other characteristics.In the past because of low bending strength, brittle, for a long time mainly as a finishing tool, the proportion of all kinds of tool materials is very small.But in recent years, due to the control of the raw material purity and particle size refinement, add various kinds of carbide, nitride, boride and oxides to improve its performance, but also through micro cracks, whisker, phase transformation, and several kinds of toughening mechanism of synergy to improve the fracture toughness, impact resistance and fracture toughness and the have greatly improved, expanding application range.

Cutting tools are tools used for cutting in mechanical manufacturing, also known as cutting tools.Generalized cutting tools include both cutting tools and abrasive tools.Using ceramic cutter can directly replace grinding (or throwing) with turning and milling to process the hardened parts, and a single process can be used to replace multiple processes, greatly shortening the process flow.In production, it can be used for general turning, boring and milling, and more successfully for precision hole machining.In addition to the use of ordinary machine tools, but also effectively used in CNC machine tools and other efficient equipment.Compared with ultra-hard tools such as diamond and CBN (cubic boron nitride), the price of ceramics is relatively low.

B. papermaking with the ceramic slag separator, the same high wear resistance, corrosion resistant special ceramics production and become, its high wear resistance and corrosion resistance and good effect of slag, in paper and pulp production enterprises play an important irreplaceable role. The high-speed paper machine with ceramic dehydration panel, molding board, wiper plate is suitable for the machine high speed paper machine speed above 100 m/min.

C. The wear resistance and high mechanical strength of ceramic plunger are widely used in petroleum exploration and textile enterprises.

D. ceramic wear-resistant fan blades mainly use alumina, zirconia, silicon nitride and silicon carbide wear-resistant ceramics.Compared with metal materials, the wear resistance ceramics has a small friction coefficient, wear resistance, high quality, good heat resistance, volume is small, small thermal expansion coefficient and superior corrosion resistance, etc, but wear resistance ceramics at the same time there are unable to bear large tensile stress and bending stress, especially unable to bear large mechanical and thermal stress or mutation of the effect of stress gradient.

About us:

Dongguan Mingrui Ceramics Technology Co., Ltd

is a professional manufacturer of ceramic structural parts. We have more than 10 senior engineers,technical backbone, more than 60 workshop technicians.

We produce strengthened structure zirconia ceramic bar, ceramic tube, ceramic shaft, ceramic plate, ceramic sleeve, ceramic valve, ceramic plunger and ceramic arm.

The products are applicable to instruments,medical instruments, clocks and electronic products, mills, energy and power, autocar and military and some other high-end areas. |

|

Our ceramic products are mainly used in the industrial field of precision ceramic structural parts, ceramic materials using high-strength zirconia (yttrium stable/magnesium stable/cerium Stable), alumina (97/99/99.5/99.7/99.9/99.99) material.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730