High Heat Temperature Ceramics Parts And Components For Industry Applications

High temperature ceramic is a kind of can in extreme high temperature environment, maintain normal ceramic parts performance unchanged, with a strong resistance to high temperature, up to 2000 ℃ (3632 ° F), high melting point, high temperature strength and high temperature creep properties of the smaller, and better thermal shock resistance, corrosion resistance, oxidation resistance and structure stability, etc.

As a result, industrial parts began to adopt high temperature ceramic materials.High temperature ceramic parts make up for the determination of metal, rubber and plastic materials and increase the service life of industrial parts.

In the material, there is a kind to call high temperature ceramic material basically make use of the mechanical property such as its intensity, hardness toughness to make all sorts of material.The appearance of high temperature ceramic structure material makes up the weakness of metal material.This kind of material can endure high temperature, not afraid of oxidation, naisuanjian corrosion, high hardness, wear resistance, the advantages of small density, as high temperature ceramic material, very suitable for, can be in commonly 2000 ℃ (3632 ° F) using high temperature environment for industry parts.

High temperature oxide ceramics (such as Al2O3, ZrO, MgO, CaO, ThO2, Cr2O3, SiO2, BeO, 3 Al2O3·2SiO2, etc.), carbide ceramics, boride ceramics, nitride ceramics and silicide ceramics, etc.

Alumina Ceramic --Al2O3

Alumina Ceramics melting point is very high, can be used as advanced refractory materials, such as crucible, high temperature furnace tubeHigh temperature ceramic parts. 3.9 g/cm3 density, bending strength is 370 ~ 450 mpa, thermal expansion coefficient of 6.7 x 10-6 / ℃ (20 ~ 100 ℃), dielectric strength of 25 ~ 30 mv/m, volume resistivity Ω · 1012 ~ 1013 cm (100 ℃ + / - 5 ℃), the relative dielectric constant of 10.0.It is often used to make crucible, porcelain boat, fireproof tube, etc.

Nitride Ceramics -- Si3N4

It is a super hard material, small density, itself with lubricity, and wear resistance, in addition to hydrofluoric acid, it does not react with other inorganic acids, corrosion resistance;They also resist oxidation at high temperatures.Its decomposition temperature is 1800 ℃ in air, in the 110 mpa nitrogen is 1850 ℃.Silicon nitride ceramics are often used to make bearings, turbine blades, mechanical seal rings, permanent mold and other mechanical components.

Boron Nitride Ceramic -- CBN

Boron nitride is white, insoluble and resistant to high temperatures.it is a new type of high temperature resistant superhard material, used for the production High temperature ceramic parts of drills, abrasives and cutting tools.High heat resistance 3000 ℃ sublimation, the strength of 1800 ℃ for 2 times at room temperature, air cooled to room temperature to 1500 ℃ for 10 times without rupture, 2800 ℃ not soften in the inert gas.

Boron Carbide Ceramics -- CB4

Boron carbide material has light weight, high hardness, high wear resistance, high impact resistance, neutron absorption and other properties, and has broad application prospects in high-tech part industry, nuclear power technology, national defense and military industry and other fields like high temperature ceramic parts.The density of 2.520 g/cm3.Melting point is 2350 ℃

Application Of High Temperature Ceramic Parts

High temperature ceramic parts adopt advanced high temperature ceramic as material, which is processed through many precise processes.With a strong resistance to high temperature, can reach up to 2000 ℃ (3632 ° F) keep parts of environment of high temperature performance, increase the use of parts cycle.

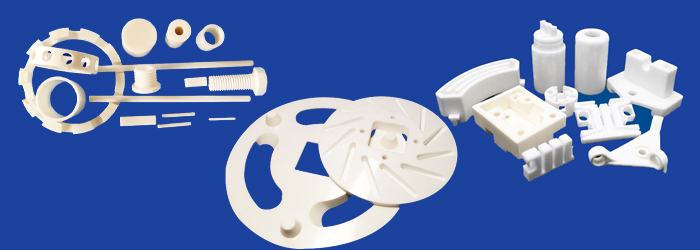

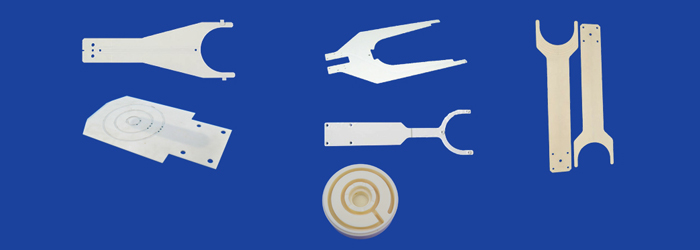

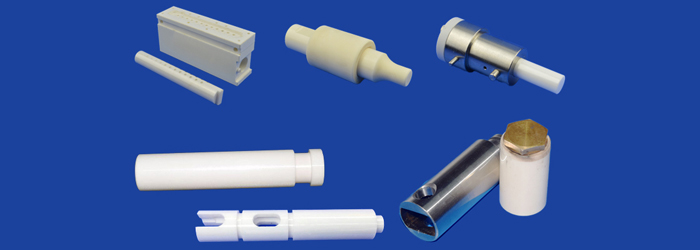

1. Classification of high-temperature ceramic parts

Ceramic bearings, bushing, hood, heat shield, valves, pistons, seals, pin rods and pipes, fasteners, screws and nuts, crucible, couple protection tubes, injection parts, flanges, nozzles, fast cutting, gears, rollers, fire materials, pumps...And so on each kind of industry, the insulation radiates the part, the equipment spare parts.

2. High temperature ceramic parts application industry

Used for aerospace equipment, power generation equipment, electronic technology equipment, mechanical equipment, chemical equipment, metallurgy, automotive, laboratory, petroleum, medical, circuit board, engine, pump, solar photovoltaic, lighting, refrigerator, induction cooker, air conditioning, textile, injection molding, cutting tools, etc.

High Temperature Ceramic Parts Processing

Machining process:

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

|

Technical reference of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized |

High Temperature Ceramic Parts Features

1.Refractory

2.Long service life

3.High Polished Surface

4. Superior Mechanical Strength

5. Anti-high Corrosion and Wear Resistance

6.Good Insulation Performance

7.High Temperature and Pressure Resistance

8.High Purity Zirconia and Alumina Ceramic Materials

9. High hardness, long service life, not easy to break and wear resistance

10.non-conductive, anti-static, ceramic material itself with the insulation of electricity and magnetism properties

11.corrosion resistance, high temperature resistance, can be applied to a specific environment, such as acid alkali resistance

High Temperature Ceramic Parts parameter

Ceramic materials(include but not limited belows)

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

Al 2O 3 |

ZrO2/Y2O3 |

ZrO2/MgO |

MgO |

SiC |

Si3N4 Reaction sintered |

Si3N4 Hot pressed |

ALN |

|

Physical properties |

|

|

|

|

|

|

|

|

|

Density (g/cm3) |

3,9 |

5,9 |

5,75 |

3,58 |

3,2 |

3,27 |

3,29 |

3,26 |

|

Molecular weight (g/mole) |

102 |

- |

- |

40,4 |

40,1 |

140 |

140 |

41 |

|

Maximum service temperature air (°C) |

1700- 1800 |

1500 |

1000 |

2200 |

1500 |

1200- 1500 |

1100- 1600 |

1000- 1800 |

|

Mechanical properties |

|

|

|

|

|

|

|

|

|

Hardness (Mohs) |

9 |

- |

- |

5,5 |

9 |

- |

- |

7 |

|

Modulus of elasticity (GPa) |

300-400 |

200 |

200 |

250-300 |

420 |

170-220 |

280-310 |

318 |

|

Poisson's ratio |

0,25 |

- |

- |

0,18 |

0,14 |

0,25-0,26 |

0,27 |

0,25 |

|

Fracture toughness (MPa.m1/2) |

2-3 |

7-13 |

6-10 |

- |

2,5-3,5 |

3,5-5 |

6,1 |

4,5 |

|

Electrical properties |

|

|

|

|

|

|

|

|

|

Dielectric constant |

9-10 |

- |

- |

9-10 |

- |

10 |

10 |

9,2 |

|

Electrical resistivity at 20°C (Ohm.cm) |

>10 14 |

10 13-10 14 |

>10 10 |

- |

10 2-10 6 |

>10 7 |

10 12- 10 15 |

>10 14 |

|

Dielectric strength (kV/mm) |

10-20 |

9 |

2-10 |

- |

- |

- |

- |

15 |

|

Thermal properties |

|

|

|

|

|

|

|

|

|

Specific heat (J/K/kg) |

900 |

400-500 |

420 |

870-880 |

750 |

690 |

680-800 |

800 |

|

Thermal conductivity (W/m/K) at 20°C |

26-35 |

2,2-3,2 |

1,5-2,5 |

40-50 |

63-155 |

9-30 |

15-43 |

180 |

|

Coefficient of thermal expansion ( 10-6) from 20 to 1000°C |

8-9 |

10-11 |

5-16 |

10-13 |

4-5 |

3 |

3,3 |

4,4-5,3 |

|

Melting point (°C) |

2050 |

2590 |

- |

2800 |

2500 |

1900 |

1900 |

2200 |

About us:

Dongguan Mingrui Ceramics Technology Co., Ltd

is a professional manufacturer of ceramic structural parts. We have more than 10 senior engineers,technical backbone, more than 60 workshop technicians.

We produce strengthened structure zirconia ceramic bar, ceramic tube, ceramic shaft, ceramic plate, ceramic sleeve, ceramic valve, ceramic plunger and ceramic arm.

The products are applicable to instruments,medical instruments, clocks and electronic products, mills, energy and power, autocar and military and some other high-end areas. |

|

Our ceramic products are mainly used in the industrial field of precision ceramic structural parts, ceramic materials using high-strength zirconia (yttrium stable/magnesium stable/cerium Stable), alumina (97/99/99.5/99.7/99.9/99.99) material.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730