Application of wear-resisting ceramic pipe in industry

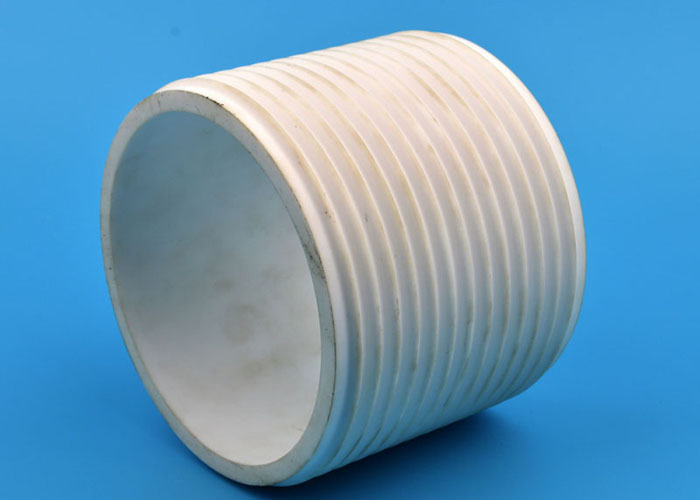

Wear-resistant ceramic pipe is manufactured by high technology production process -- self-combustion high temperature clutch synthesis method.The pipe from inside to outside, respectively by three layer, transition layer and steel corundum ceramics, ceramic layer is above 2200 ℃ high temperature to form dense alumina porcelain (AL2O3), with steel tube forming strong through the transition layer.

The composite pipe gives full play to the characteristics of high strength, good toughness, impact resistance, good welding performance, high hardness, high wear resistance, corrosion resistance and heat resistance of corundum porcelain, and overcomes the low hardness, poor wear resistance and ceramic toughness of steel pipe.

1. Application in metallurgy and power industry

Metallurgy, power industry transport coal powder, ash, mud, lime gypsum slurry and other needs to consume a large number of metal pipes every year.Adopting ceramic composite pipe instead of other pipe, it has the characteristics of high wear resistance, long life, convenient installation and remarkable economic benefit.By shandong liaocheng chang embellish thermal power plant, liaocheng power plant, Beijing northern new building materials group, henan hebi power plant, gansu of out power plant, taiyuan coal preparation plant, hunan shimen power plant, hebei jinniu energy co., LTD shotcrete-bolt coal preparation plant, xingtai coal preparation plant and other industrial operation, its operation life is more than a dozen times and even more steel pipe.

2. Application in mining and coal industry

(1) mine: mine filling, concentrates and tailings transport on the pipeline wear seriously, the previous use of mineral powder transport pipeline such as panzhihua, daye mine life is less than a year, the pipe can be changed to the life of about 5 times.

(2) coal: wet conveying is generally adopted for coal preparation and long-distance pipeline transportation. It is required that the conveying pipe is both wear-resistant and corrosion-resistant. The pipe can be used as the long-life conveying pipe with considerable economic benefits.

3. Types of ceramic wear-resisting elbow

Centrifugal casting of composite ceramic elbow

Centrifugal casting composite pipe is a composite pipe manufactured by "self-ignition high-temperature synthesis - high-speed centrifugal technology", forming uniform, compact and smooth ceramic layer and transition layer under high temperature and high speed.In addition, the working temperature of 850 ~ 900 degrees ceramic will not fall, the weight is lighter, composite ceramics with hardness anti-wear, to solve the past with thickness anti-wear.At present, straight pipe, elbow, elbow, tee and other serious wear in the industry use effect is very good.

Full name ceramic lined composite steel pipe.

The composite pipe gives full play to the characteristics of high strength, good toughness, impact resistance, good welding performance, high hardness, high wear resistance, corrosion resistance and heat resistance of corundum porcelain, and overcomes the low hardness, poor wear resistance and ceramic toughness of steel pipe.Therefore, the composite pipe has good wear resistance, heat resistance, corrosion resistance and resistance to mechanical and thermal impact, good weldability and other comprehensive properties.It is an ideal pipeline for conveying granular materials, grinding and corrosive medium.

Patch wear-resistant tube

Stick piece wear-resisting tube is to use adhesive paste alumina ceramic piece on the inner wall of the pipe.The production process is simple and the production cycle is long.The service environment shall not exceed 150 degrees.

Spot welded bayonet type wear-resisting tube

Spot welding bayonet type wear-resisting pipe is to stick alumina ceramic sheet with hole in the middle on the inner wall of the pipe with high-temperature strong adhesive, and weld the ceramic firmly on the inner wall of the pipe through small holes with spot welding technology.To protect the solder joint, top with ceramic cap.This kind of product manufacture craft is relatively complex, the manufacture cycle is longer, the cost is higher.

(1) the pipe does not pollute and does not adhere to the molten aluminum solution.Aluminum smelting equipment, aluminum conveying pipe and lifting pipe, which are sensitive to iron pollution and require heavy labor to sort and maintain after use, are ideal materials at present.

(2) the pipe is due to good wear resistance and heat corrosion.Suitable for conveying corrosive materials containing solid particles and corrosive medium such as high-temperature corrosive gas and sulfur-bearing geothermal water.

4. Features of shs-self-ignition ceramic composite pipe

1. Good wear resistance

As the inner lining of the ceramic composite pipe is corundum ceramics (a-al2o3), the mohs hardness can reach up to 9.0, equivalent to HRC90 and above.Therefore, it has high abrasion resistance to grinding medium transported by metallurgy, electric power, mining, coal and other industries.It has been proved by industrial operation that its wear-resisting life is ten or even dozens of times that of hardened steel.

2. Low running resistance

As the inner surface of SHS ceramic composite pipe is smooth and never corrodes, there is no convex spiral line on the inner surface of seamless steel pipe.The inner surface roughness and clearwater resistance characteristics of the inner surface tested by relevant testing units are better than that of any metal pipe, and the clearance resistance coefficient is 0.0193, slightly lower than that of seamless pipe.Therefore, the pipe has the characteristics of low running resistance, which can reduce the running cost.

3. Corrosion resistance and scale prevention

As the steel ceramic layer is (a-AL2O3), a neutral nature.Therefore, it has the characteristics of acid and alkali resistance, seawater corrosion resistance and scale prevention.

4, the temperature resistance and heat resistance is good

As the corundum ceramics (a-AL2O3), for a single stable crystalline structure.So the pipe can be in - 50-700 ℃ temperature range of normal operation for a long time.Material linear expansion coefficient is 6-8 10-6/0c, which is about 1/2 of steel pipe.The material has good thermal stability.

5. Low project cost

Ceramic composite pipe is light in weight and suitable in price.It is 50% lighter than the cast stone pipe of the same inner diameter.Compared with the wear-resisting alloy tube weight of 20-30%, and wear-resisting, corrosion resistance is good, because the service life is long, thus supporting and lifting expenses, handling expenses, installation costs and operating costs are reduced.According to the comparison of engineering budget and engineering practice between the design institute and the construction unit, the engineering cost of the pipe is equivalent to that of cast stone, and is about 20% lower than that of wear-resisting alloy pipe.

6. Convenient installation and construction

Because of its light weight and good welding performance.Therefore, welding, flanges and rapid connection can be adopted to facilitate construction and installation, and reduce installation costs.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

Skype: admin@cerampart.com

We chat: +86 18122974730

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730