: +86 18122974730

: +86 18122974730 : +86 0769-85090316-8038

: +86 0769-85090316-8038 : admin@cerampart.com

: admin@cerampart.com- Features -

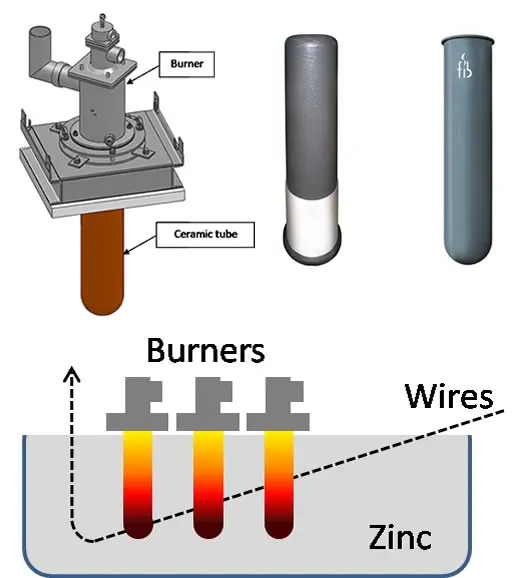

Ceramic Heater Tube is used as basic material (Principal features of KN-101)

(1) High strength : High bending strength of 780MPa without deterioration up to 800deg. C.

(2) High density : High dense material with porous ratio of less than 0.3%

(3) High toughness : The highest fracture toughness(KIC) of 7.2MPa x m1/2 among ceramic materials

(4) High performance : Almost no erosion in molten aluminum and low wettability

Variety of type

(A) Vertical type : Two kinds of Metal Flange Type and One Body Ceramic Type

are prepared

(B) Horizontal type : Tapered end by one piece forming is provided on demand

(C) Pencil type : Small diameter of 28 and 30mm are provided

*All types can be applied to tubes equipped with heater

Wide range of dimension

(Maximum dimension) Inner diameter 350mm , Length 1300mm

(Current available dimension) Others are available upon request

*Thickness : Standard wall thickness is 10mm

As a the manufacturer of ceramic tubes, us offer a wide the type or sizes of the ceramic tube for industry machinable and parts applications.our ceramic tubes are made of Zirconia, Alumina, Silicon and other advanced ceramics. In stocks and the special specifications can be customized.

Ceramic tubes available stocks:

| Tube series | Round Double Bore | Round Four Bore | Oval Double Bore | ||||

| OD | ID | OD | ID | OD | ID | OD | ID |

| .050" | .020" | .063" | .016" | .063" | .016" | .077"/.051" | .014" |

| .063" | .031" | .094" | .025" | .094" | .020" | .120"/.070" | .031" |

| .094" | .040" | .109" | .031" | .109" | .020" | .163"/.112" | .040" |

| .094" | .063" | .125" | .031" | .188" | .031" | ||

| .100" | .050" | .125" | .040" | .219" | .050" | ||

| .125" | .063" | .156" | .052" | ||||

| .156" | .094" | .188" | .040" | ||||

| .188" | .094" | .200" | .052" | ||||

As a manufacturer of ceramic tubes and related ceramic parts, we support machining or customization of ceramic tubes of special sizes and shapes.

The property of the ceramic tubes:

·Excellent physical & chemical stability ·High temperature resistance(up to 1750℃)

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity..

Ceramic material composition:

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Thermal characteristics:

Ceramic materials have high melting point (mostly in above 2000 ℃), and has excellent chemical stability at high temperature;The thermal conductivity of ceramics is lower than that of metal materials, and ceramics are also good insulation materials.At the same time, the linear expansion coefficient of ceramic is lower than that of metal. When the temperature changes, ceramic has good dimensional stability.

Electrical characteristics:

Most ceramics have good electrical insulation, so they are widely used to make insulation devices of various voltages (1kV~110kV).Ferroelectric ceramics (barium BaTiO3) have a high dielectric constant and can be used to make capacitors. A few ceramics also have the characteristics of semiconductor and can be used as rectifiers.

Customization & Machining Service:

As a manufacturer of ceramic tubes and related ceramic parts, we support machining or customization of ceramic tubes of special sizes and shapes.High Precision, Fast Delivery Time, High Composition.For more tubes, please contact us now!!

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve