Ceramic threaded tubeCeramic threaded tube hardness strength and wear abrasion resistance alumina zirconia tubes

- Brand:OEM

- Material:Alumina Zirconia Si3N4 SiC

- Precision:0.001mm

- Features:high precision

- Color:Can be customized

- Customized:Mingrui ceramics can be customized according to customer requirements

Ceramic Threaded Tube Hardness Strength And Wear Abrasion Resistance Alumina Zirconia Tubes

As a Professional Advanced Technology Ceramic Manufacturers,

Us Support To Customize Different Specifications Of Ceramic Components

Ceramic threaded tube has high strength, good toughness, impact resistance, good welding performance and corundum porcelain high hardness, high wear resistance, corrosion resistance, heat resistance, overcome the low hardness of steel pipe, poor wear resistance and ceramic toughness.

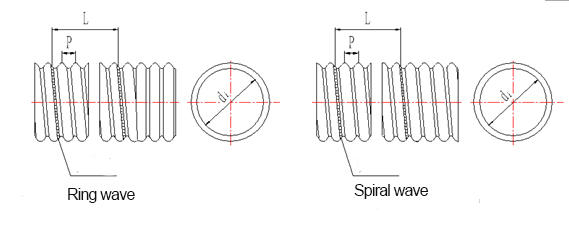

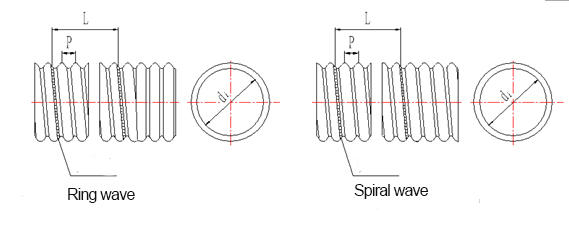

Ceramic threaded tube can be, unilateral threaded pipe, pipe body full thread, pipe internal thread.

The Ceramic threaded tube is divided into outer thread pipe and inner thread pipe, and the inner thread pipe is also called dry steam pipe, inner rib pipe or inner fin pipe.It is mainly used in dry evaporator in central air conditioner.

The ceramic inner threaded tube is also called dry steam pipe, inner rib pipe or inner fin pipe.In the central air conditioning machine it is mainly used in dry internal threaded tube evaporator, heat exchange, outside the pipe who is cooled by the tube evaporative expansion of the refrigerant;It is also used in home and commercial air-conditioning heat exchangers or for high heat tubes.The internal surface area per unit length of internal threaded pipe is 1.5-2 times that of plain copper pipe, and its heat transfer coefficient is 1.5-2.4 times that of plain copper pipe of the same specification.

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Available color: white,black,blue,yellowish,et

|

Properties |

Units |

AL2O3 |

ZrO2 |

SiC |

Si3N4 |

|

Density |

g/cm3 |

3.65-3.93 |

5.95-6.0 |

3.12 |

3.23 |

|

Water absorption |

0 |

0 |

0 |

0 |

0 |

|

Coefficientof thermal expansion |

10-16/k |

7.9-8.5 |

10.5 |

3 |

3.2 |

|

Modulus of elasticity young`s mod |

GPa |

280-340 |

210 |

440 |

300 |

|

Poission`s ratio |

/ |

0.21-0.22 |

0.3 |

0.17 |

0.26 |

|

HV hardness hv |

MPa |

1650 |

1300-1365 |

2800 |

1500 |

|

Flexural strength |

MPa |

310 |

950 |

390 |

720 |

|

Flexural strength(700℃) |

MPa |

230 |

210 |

380 |

450 |

|

Compressive strength |

MPa |

2200 |

2000 |

1800 |

2300 |

|

Fracture toughness |

MPa*m1/2 |

4.2 |

10 |

3.9 |

6.2 |

|

Heat conductivity |

W/m*k |

26-30 |

2-2.2 |

120 |

25 |

|

Electrical resistivity |

Ω*mm2/m |

>1016 |

>1015 |

>103 |

>1013 |

|

Max use temperature |

℃ |

1750 |

1050 |

1550 |

1050 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

high |

|

Dielectric constant |

/ |

9.6 |

29 |

9.66-10.03 |

/ |

|

Dielectric strength |

KV/mm |

8.7 |

9 |

/ |

/ |

|

Thermal shock resistance |

△T(℃) |

180-220 |

280-350 |

230-260 |

/ |

|

Tensile strength |

MPa |

248 |

250 |

/ |

/ |

|

Precision of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Smoothness |

Highest possible mirror |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized |

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surface |

General types of ceramic tubes:

single-hole ceramic tubes, porous ceramic tubes, irregularly porous ceramic tubes,ceramic tube insulator,ceramic tube heater...

: +86 18122974730

: +86 18122974730 : +86 0769-85090316-8038

: +86 0769-85090316-8038 : admin@cerampart.com

: admin@cerampart.com