With the continuous development of science and technology, the application fields of alumina ceramics are becoming more and more extensive, so what are the applications of alumina ceramics in machinery? Let Mingrui Ceramics, a professional manufacturer of alumina ceramic structural parts, briefly introduce it.

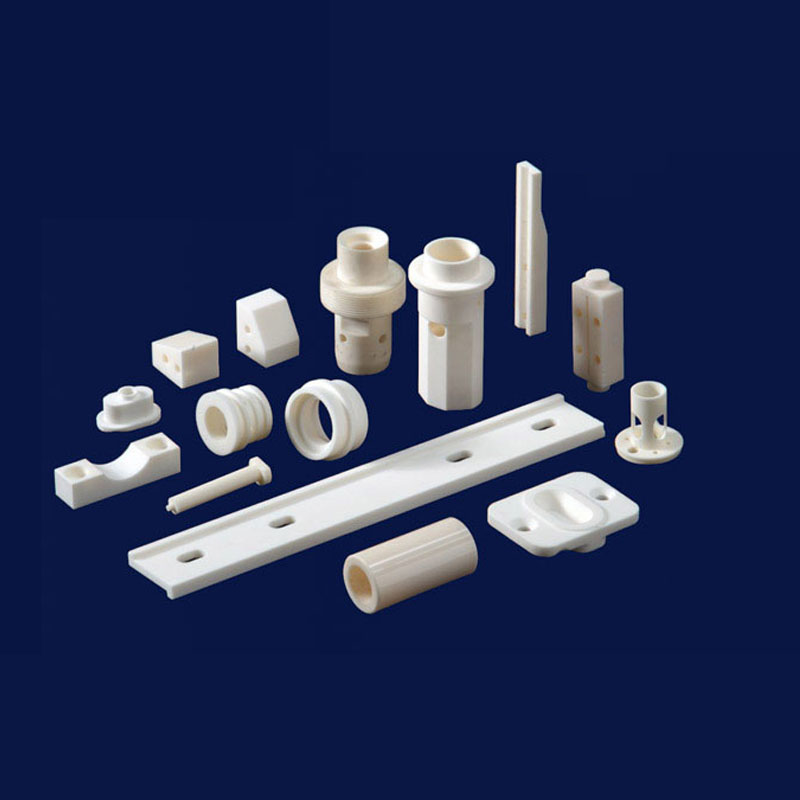

alumina ceramic structural parts

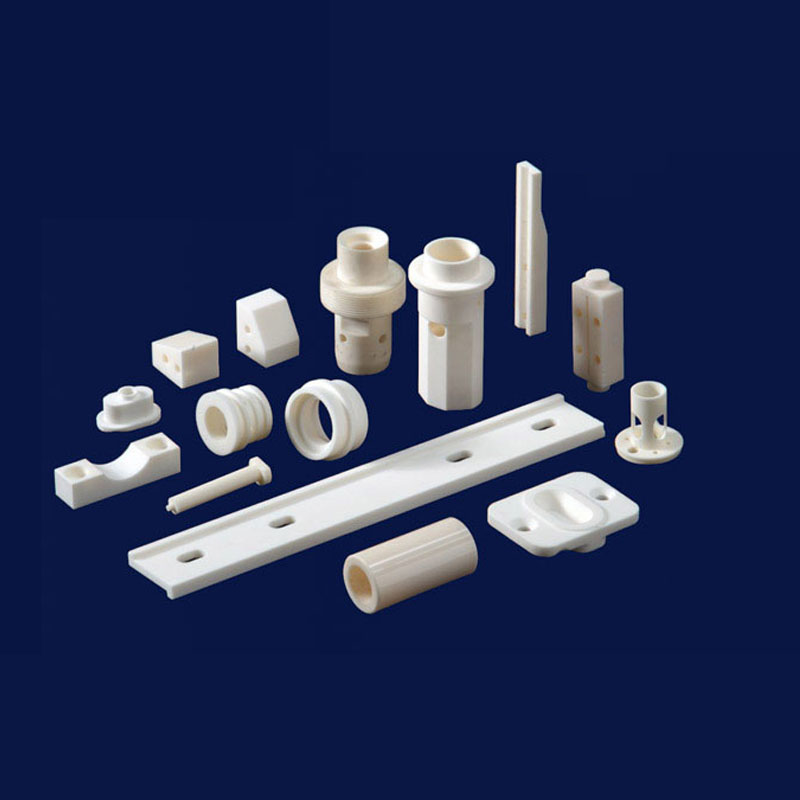

alumina ceramic structural parts

1. Alumina ceramic tools

The better cutting speed of alumina ceramic tools is higher than that of ordinary cemented carbide tools, which can greatly improve the cutting efficiency of different materials. With the extensive research of scientists, other components are added to form two phases or exist in the form of solid solution in the matrix. Among the alumina-based composite ceramics and whisker-reinforced ceramics.

These technologies make up for the shortcomings of pure alumina ceramics (purity of alumina ceramics), thereby improving its cutting performance and durability.

2. Pure alumina ceramic cutter

Pure alumina ceramic tools refer to high-purity alumina ceramics containing only a small amount of oxides. In pure alumina ceramics, ZrO2 can be added as a sintering aid to improve its fracture toughness.

Pure alumina ceramic tools have good high temperature performance and wear resistance, but have low bending strength and poor impact resistance. At present, they are increasingly replaced by various composite Al2O3 ceramic tools.

3. Composite alumina ceramic tool

Al2O3-carbide ceramic cutting tools are made by adding certain carbides to alumina to improve its strength, wear resistance, impact resistance and high temperature performance.

Due to the addition of metal, the connection strength between alumina and carbide is improved, and the performance is improved. This type of ceramic tool is suitable for processing hardened steel, alloy steel, manganese steel, chilled cast iron, nickel-based and cobalt-based alloys, and non-metals Materials, etc.

4. Toughened alumina ceramic tools

Toughened alumina ceramic tool refers to the addition of toughening or reinforcing materials to the alumina matrix. Currently commonly used toughening methods include: ZrO2 phase transformation toughening, whisker toughening, and second phase particle dispersion toughening.

About Mingrui Ceramics

Mingrui Ceramics is a professional manufacturer and supplier of alumina ceramic structural parts, providing customers with high-quality customized production. Alumina ceramic structural parts are widely used in instrumentation, food and medicine, solar photovoltaic, mechanical hardware, laser semiconductor, petrochemical industry , Automotive, military, aerospace and other high-end fields.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730