Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Due to the unique properties of electrical ceramics, their applications are becoming more and more common.Most importantly, it has also attracted more researchers for research and development, which makes it possible to control air pollution and the energy of molten metals.However, many problems remain.Let us and small make up to learn the key content of electrical ceramics.

The higher the thermal conductivity of electrical ceramics, the larger the heat transfer area, the shorter the heat transfer distance, the higher the heat transfer energy, the easier to take away the heat.However, the vast majority of the thermal insulation on the aluminum substrate has little thermal conductivity, making it impossible to conduct heat from the led to the aluminum substrate and allowing the entire cooling channel to flow smoothly.Since there is an insulating layer between copper and aluminum in the middle of the aluminum substrate, the insulating material with high thermal resistance is this layer.

Alumina ceramics are electrical ceramics.First, the overall brittleness of alumina ceramics needs to be improved.Brittleness is the most fatal defect of alumina ceramics, which limits the application of black alumina ceramics to a large extent.Although many professionals have studied this problem, they can solve it.The substance of the decision has yet to be determined.The main reason to improve the strength of electrical ceramics is that they have more pores and their strength performance is greatly reduced.

If the strength of electrical ceramics can be optimized in a timely and effective manner, these problems can be solved earlier, and the control methods such as pore size, shape size and distribution of alumina ceramics can be improved to make porous alumina ceramics more widely used in the whole.The scale of the industry is expanding rapidly: as the basic material of other industries or fields, the ceramic products of microcrystalline alumina are affected and restricted by the development level of other industries.At present, the application of alumina ceramics is more and more extensive, and the consumption is more and more large, especially in the production of wear-resistant engineering ceramics and architectural ceramics.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

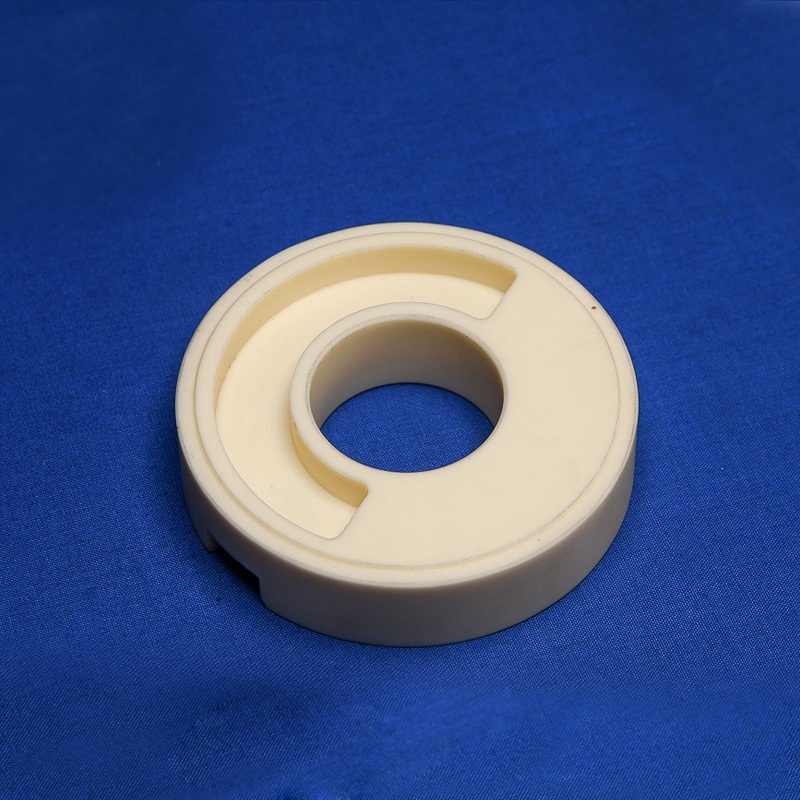

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS