Ceramic ball valve in industrial chemical equipment has what effect

Coal-to-oil chemical plant, like other petrochemical plants, cannot be separated from pipelines, valves and other equipment.The biggest difference between the valves used in coal liquefaction and those used in petrochemical plants is the harsh requirements on corrosion resistance.

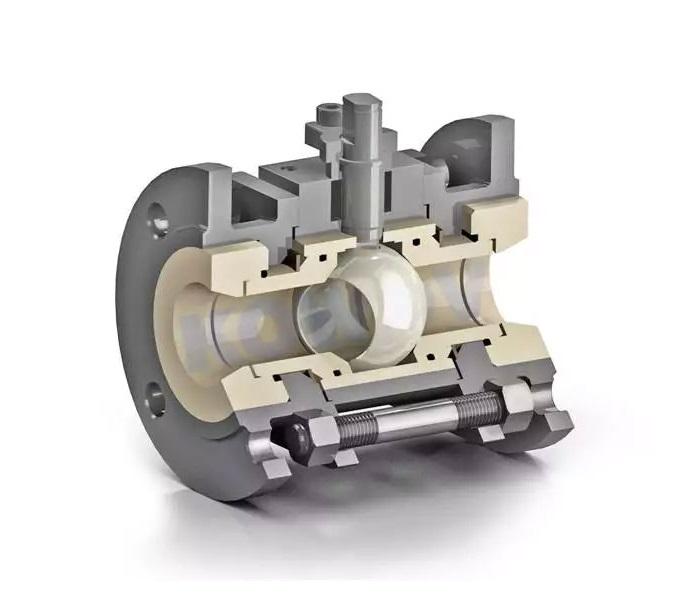

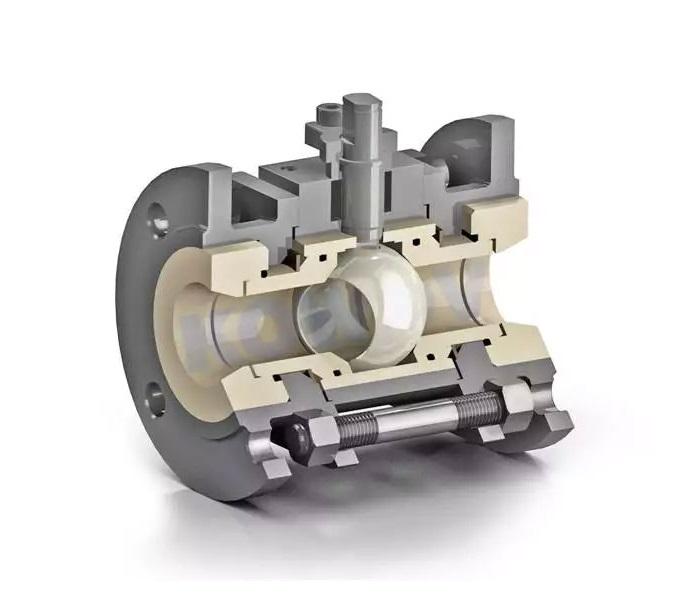

The wear-resisting valve used in coal-to-oil chemical industry needs to be treated differently due to its different operating conditions, different process media, different degrees of danger and different corrosiveness.In view of the above factors, the design and development of some high quality valves, such as high performance metal hard seal butterfly valve, high temperature hard seal ball valve for coal chemical industry and pneumatic ceramic ball valve, to solve the problem of pipeline control in the field of coal-to-oil chemical industry.Ceramic ball valves are currently mainly used in electric power, petroleum, chemical, metallurgical, mining and sewage treatment and other industrial fields, can meet the high wear, strong corrosion of the use of the environment, and has a long service life.

Ceramic ball valve ceramic and the traditional meaning of ceramics are completely two concepts: in terms of raw materials, advanced ceramics generally take purified oxides, nitride, silicides, borides and carbides as the main raw materials;In terms of composition, advanced ceramics are pure compounds, so their composition is determined by artificial ratio, and their performance is determined by raw material purity and technology.In terms of technology, advanced ceramics are widely used in vacuum sintering, protective atmosphere sintering, hot pressing and hot isostatic pressing.

The chemical inertia of 99.5% alumina structural ceramics is very strong, and most organic and inorganic substances do not react, will not pollute the medium, for most acid and alkali, the physical and chemical properties of structural ceramics are very stable, even after many years of service performance will not degradation.And its hardness reaches HRA88, only lower than diamond, silicon nitride, silicon carbide, this characteristic also determines that ceramic valve has very good wear resistance.

Due to the high sealing requirements of ceramic ball valve, up to 800kg, so the ball must be very round, and the surface must be very smooth, the error cannot exceed 5‰, so the processing technology must be precise.Ceramic cylinder is usually processed by isostatic pressure first.And then you modify it to get ceramic balls;Sintering at 1450 ~ 1600℃ for 15h;Finally, the ceramic ball can be obtained by machining.The ball valve of each specification has two kinds of spool, v-type and o-type, which can adjust the flow with high precision;At the same time, the use of reinforced spool valve runner wear to minimize.

With the continuous development and progress of science and technology, ceramic materials in the formulation, molding, processing and assembly technology and other aspects of the technology is more mature and complete, ceramic valves with its excellent performance more and more to get the recognition of the valve industry.The successful experience of making ceramic valves can also be applied to a wide range of engineering fields, such as desulfurization systems in power plants, washing and dressing systems, fluid flow control systems and chemical industry and other corrosive occasions.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730