Market demand analysis of ceramic filling pumps

Time: 2020-03-03 Writer: mingrui

Market demand analysis of ceramic filling pumps

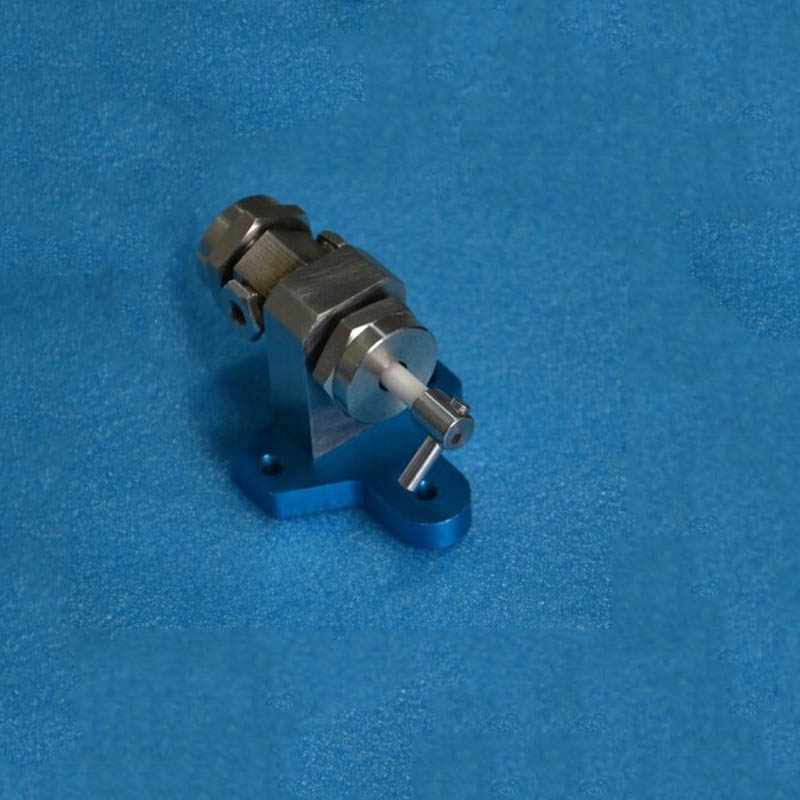

Mingrui ceramic pump has the following characteristics:

(1) It adopts high-performance technical ceramic materials, which have high hardness, wear resistance, high temperature resistance and corrosion resistance. Ensure material performance is reliable.

(2) The microporous structure obtained by the unique working means of the plunger working surface has self-lubricating effect, which changes the mechanism of sliding friction and lubrication of the conventional plunger pump.

(3) The inner cavity surface adopts a fluid structure with no dead angles or grooves. The surface of the inner cavity is matched with the surface of the plunger by an advanced high-precision internal and external cylindrical grinding machine to the mirror surface, and the outer surface is vibrated and polished to facilitate cleaning and disinfection.

(4) The pump body structure is sealed with 316L stainless steel for easy disassembly.

(5) These products have been tested for corrosion resistance and acid and alkali resistance, and their indicators have reached the level of similar foreign products.

(6) The shape and size can be designed and processed according to user needs.

In the past few years, new industrial ceramic materials have been widely used in various industries. Especially in the pharmaceutical industry, ceramic filling pumps are essential for the filling of water injections, freeze-dried powders and oral liquids. component.

Ceramic materials have the following characteristics with respect to metal materials:

(1) Ceramic materials are environmentally friendly materials, and the material properties are in full compliance with the hygiene level requirements of food and pharmaceutical production standards;

(2) The ceramic material has extremely high hardness and good wear resistance, and the ceramic filling pump wears little during use;

(3) The ceramic material has high temperature resistance and high acid and alkali resistance, which ensures no damage to the pump itself during cleaning and high temperature sterilization;

(4) High filling precision, high-precision machining method of ceramic materials, and behavioral size are not easy to change during use, ensuring that the precision can meet the production requirements during the years of use. Along with the rapid development of Chinese pharmaceutical companies and the increasing demand for pharmaceutical quality, advanced filling solutions can meet the growing demand.

More about the ceramic,please contact us,thanks.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730