Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730As an important part of chemical equipment, the crucible is a vessel for melting and refining liquid metal and heating and reacting between solid and liquid. It is the basis for ensuring the smooth progress of chemical reactions.

As an important part of chemical equipment, the crucible is a vessel for melting and refining liquid metal and heating and reacting between solid and liquid. It is the basis for ensuring the smooth progress of chemical reactions.

Historically, crucibles were originally made of clay, and one of the earliest uses of platinum was also to make crucibles. But with the development of preparation technology, crucibles can now be made of any material that can melt or change its contents.

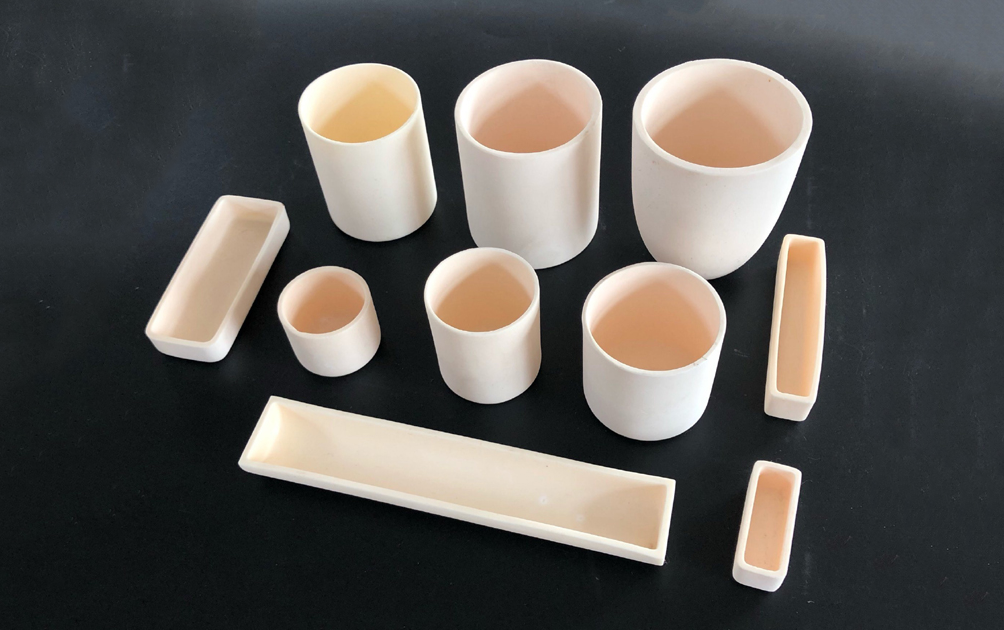

There are many types, models, and specifications of the crucible, which can be selected arbitrarily, which has strong applicability, and can ensure the purity of the smelted material.

The ceramic crucible is an important part of the crucible. The ceramic crucible can be divided into quartz crucible, corundum crucible, boron nitride crucible, zirconia crucible, etc to the raw materials, which are used on different occasions according to their properties.

Since the first two are more common, everyone has a better understanding of them; but the latter two are less used, and most people may be unfamiliar with them, but in some fields, they also play an irreplaceable role. In the following, Mingrui Ceramics will give a brief introduction and summary of these different types of ceramic crucibles to see where they are most suitable.

1. Quartz Ceramic Crucible

Quartz ceramic crucible, the full name of high-purity fused silica ceramic crucible (silica content ≥99.9%), is a ceramic crucible made of high-purity fused silica as raw material, with fine structure, low thermal conductivity, low thermal expansion coefficient With good thermal shock stability, good electrical performance, and good chemical resistance, quartz ceramic crucibles are widely used in the glass deep processing industry, metallurgical industry, electronics industry, chemical industry, aerospace, and other fields. Under normal circumstances, its shapes are mainly square and cylindrical.

With the attention and development of environmentally friendly energy, solar energy as a green energy source is generally valued by countries all over the world. The amount of polysilicon used for solar energy conversion has increased sharply, which has promoted the rapid development of polysilicon production. Therefore, the amount of corresponding large-size thin-walled square fused silica ceramic crucible is also increasing rapidly, and its market prospects are very promising in the world.

2. Corundum (Alumina) Crucible

Corundum crucible, the scientific name alumina crucible, people usually call the crucible with more than 95% alumina content as corundum crucible. Corundum crucible is strong and resistant to melting, high-temperature resistance, acid and alkali resistance, rapid cold and extreme heat resistance, and chemical corrosion resistance. It is suitable for using some weakly alkaline substances such as anhydrous Na2CO3 as a flux to melt samples, but not suitable for Na2O2, NaOH, etc. Strong alkaline substances and acidic substances are used as flux melting samples…

The 99.70% purity alumina crucible has good high-temperature insulation and mechanical strength in an oxidizing and reducing atmosphere of 1650℃-1700℃, and the maximum temperature can reach 1800℃ in a short period of time. Depending on the application conditions, alumina crucibles are available in a variety of sizes and shapes.

3. Boron Nitride Crucible

Commonly used types of boron nitride are cubic boron nitride (C-BN) and hexagonal boron nitride (P-BN). Among them, boron nitride crucibles are usually composed of P-BN. P-BN ceramics have good heat resistance, thermal stability, thermal conductivity, high-temperature dielectric strength, and are ideal heat dissipation materials and high-temperature insulation materials.

Due to the excellent chemical stability of P-BN, it can resist the erosion of most molten metals, and because of the above-mentioned high-temperature insulation characteristics, high thermal conductivity, and low thermal expansion performance, it is most suitable for strict environmental conditions such as semiconductor manufacturing processes. Under the materials used. P-BN crucibles are often used for smelting metals and semiconductors. It can be used at a temperature of up to 1800°C under vacuum and up to 2100°C under atmosphere protection. It is generally protected by nitrogen or argon (atmosphere protection is to prevent oxidation of the crucible ).

4. Zirconia Crucible

The melting point of zirconium oxide is higher than that of zirconium, reaching 2700℃. It is one of the best refractory materials in nature. Slag, etc. react, so the crucible made of zirconia material can successfully smelt platinum, palladium, ruthenium, cesium, and other platinum group noble metals and their alloys.

It is worth noting that although zirconia is more expensive than alumina, it is a special oxide refractory material that cannot be replaced by other oxide materials when used in high-temperature furnaces above 2000°C.

5. Yttrium Oxide Crucible

Yttrium oxide (Y2O3) ceramic is a high-performance ceramic with excellent heat resistance, corrosion resistance, and high-temperature stability. The melting point of yttrium oxide is greater than 2400℃, and it is difficult to react with some active metals (such as Ti, Al, Hf, Nb, etc.) at high temperatures. Crucibles with high-purity Y2O3 as the main composition have the potential to be used to melt Ti and Ti alloys, or any oxygen-sensitive melting process.

However, due to the high melting point of Y2O3, it is difficult to process. Some foreign manufacturers use the hot isostatic pressing (HIP) method to prepare it. At the same time, the manufacturer also remarked that because Y2O3 itself is very brittle, if the heating or cooling speed is too fast (the manufacturer’s mark is higher than 5℃/min), the crucible may crack.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS