Functional features of ceramic bearing

Time: 2019-01-26 Writer: mingrui

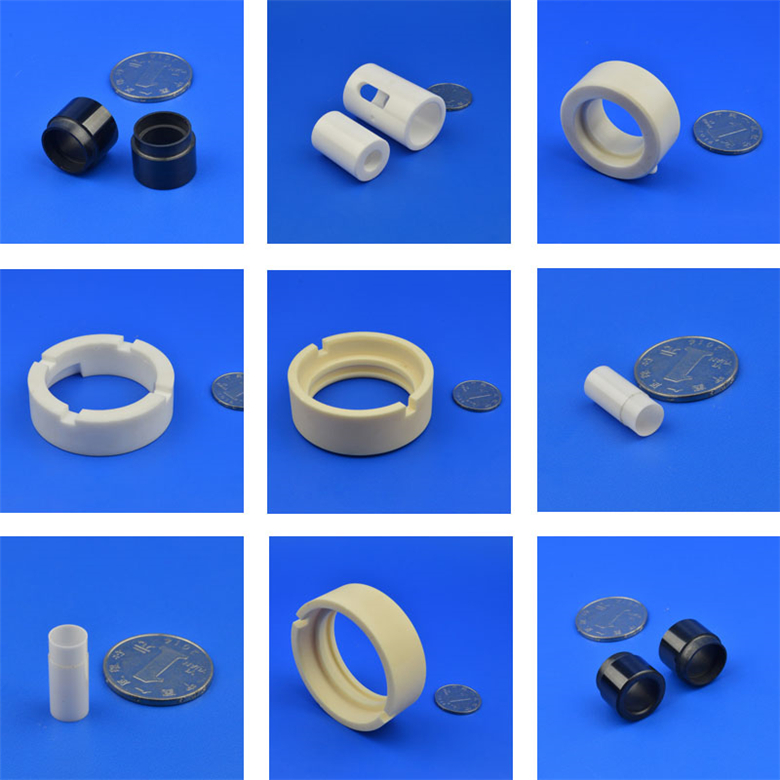

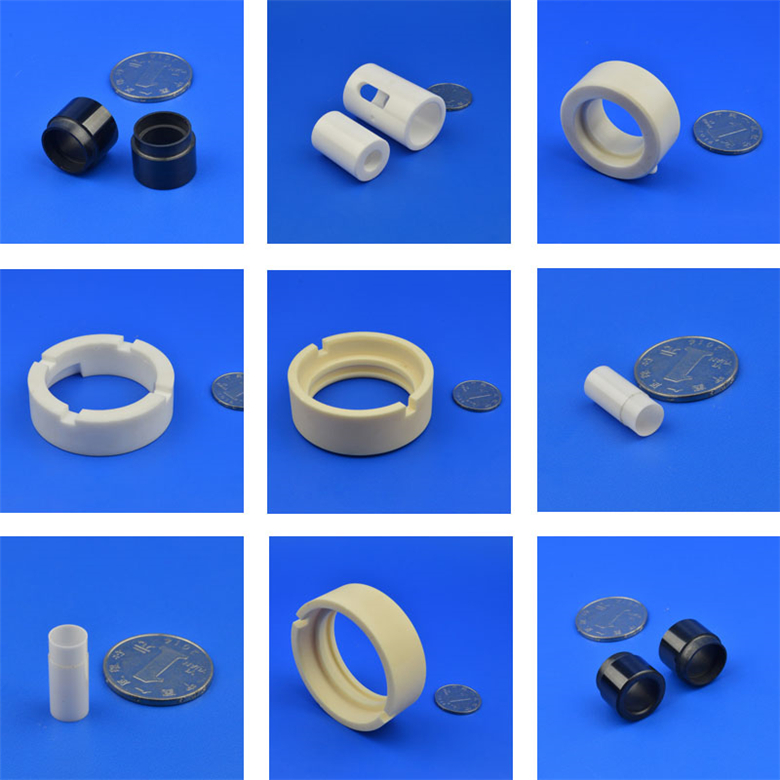

Functional features of ceramic bearing

Ordinary bearing steel AISI52100(GCr15), stainless steel AISI440(9Cr18), silicon nitride (Si3N4) and zirconia (ZrO2)

Advantages of ceramic bearing

First, because ceramics are almost not afraid of corrosion, so ceramic rolling bearings are suitable for the harsh conditions in which corrosive media.

Second, because the density of ceramic rolling ball is lower than that of steel, the weight is much lighter, so the centrifugal effect of the outer ring can be reduced by 40% when rotating, thus greatly extending the service life.

Thirdly, ceramic is less affected by thermal expansion and cold contraction than steel, so when the bearing clearance is fixed, the bearing can be allowed to work in the environment with more drastic temperature difference.

Fourth, because the elastic modulus of ceramics is higher than that of steel, it is not easy to deform under stress, so it is conducive to improving the working speed and achieving higher accuracy.

The main purpose of ceramic bearing

Ceramic bearing has the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetoelectric insulation, oil-free self-lubrication, high speed and so on.It is widely used in aviation, aerospace, navigation, petroleum, chemical industry, automobile, electronic equipment, metallurgy, electric power, textile, pump, medical equipment, scientific research, national defense and military and other fields.

Ceramic bearing rings and rolling bodies are made of all-ceramic materials, including zirconia (ZrO2), silicon nitride (Si3N4) and silicon carbide (Sic).The retainer is made of polytetrafluoroethylene, nylon 66, polyether imide, zirconia, silicon nitride, stainless steel or special aviation aluminum.

Application field of ceramic bearing

Medical instruments, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, food processing machinery.

In aerospace, navigation, nuclear industry, petroleum, chemical industry, textile industry, machinery, metallurgy, electric power, food, locomotive, subway, high speed machine tools and scientific research and national defense military technology need to be in high temperature, high speed, cryogenic, inflammable, explosive, corrosive, vacuum, electrical insulation, non-magnetic, and other special work under the conditions of dry friction, the ceramic bearing indispensable alternative role is gradually known by people.

Along with the advance of processing technology, craft level is increasing day by day, declining the cost of the ceramic bearing, has been from the past only in some small high, refined, pointed areas within the scope of application, gradually extended to the national economy each industry, product market prices are also gradually close to the practical application, reach the level of user acceptance, the application of ceramic bearing large wave is coming!

Use classification of ceramic bearing

(1) high-speed bearing: it has the advantages of cold resistance, low stress elasticity, high resistance to pressure, poor thermal conductivity, light weight, small friction coefficient, etc., and can be applied in high-speed spindle and other high-precision equipment with a speed of 12,000r/min to 75000r/min;

(2), high temperature resistant bearing: the material itself has resistance to high temperature 1200 ℃, and good self-lubrication, temperature between 100 ℃ to 800 ℃ is not caused by temperature difference expansion.Can be used in furnace, plastic, steel and other high temperature equipment;

(3) corrosion resistant bearing: the material itself has the characteristics of corrosion resistance, which can be used in the fields of strong acid, strong alkali, inorganic, organic salt, sea water, etc., such as electroplating equipment, electronic equipment, chemical machinery, shipbuilding, medical equipment, etc.

(4) anti-magnetic bearing: no magnetic, so no dust absorption, can reduce the bearing surface peeling, thus reducing the running noise.Can be used in demagnetization equipment.Precision instruments and other fields.

(5) electrically insulated bearing: due to its high resistivity, the bearing can be free from arc damage and can be used in various power equipment requiring insulation.

(6) vacuum bearing: due to the unique oil-free self-lubrication characteristics of ceramic materials, it can overcome the difficulty that ordinary bearings cannot be lubricated in the ultra-high vacuum environment.Note: for the above five types of bearings, the same set of bearings can be used in high temperature, high speed, acid-base, magnetic field and non-insulation. However, due to different material properties (please refer to the performance table of rare earth ceramic materials), customers are required to select the most suitable ceramic bearing according to the application occasions.

The material classification of ceramic bearing

zirconia

All ceramic bearing with the characteristics of anti-magnetoelectric insulation, wear resistance and corrosion resistance, oil-free self-lubrication, high temperature and cold resistance, can be used in extreme harsh environment and special working conditions.The ferrules and rolls are made of zirconia (ZrO2) ceramic, the retentors are PTFE (polytetrafluoroethylene) as standard, and glass fiber reinforced nylon 66 (rpa66-25), special engineering plastics (PEEK, PI), stainless steel (AISISUS316), brass (Cu) are generally available.

Silicon nitride

Silicon nitride all-ceramic bearing rings and rollers are made of silicon nitride (Si3N4) ceramic materials. Generally, rpa66-25, PEEK, PI and bakelite pipe with phenolic sandwich are also available.SiN4 all-ceramic bearing is suitable for higher speed and load capacity as well as higher ambient temperature than ZrO2 material.At the same time, it can provide precision ceramic bearing for high-speed, high-precision and high-rigidity spindle, with the highest manufacturing accuracy UP to P4 to UP level.

Full ball

One side of full ball type all-ceramic bearing has added ball notch. Because of the design without cage structure, more ceramic balls can be loaded than the bearing of standard structure, so as to improve its load capacity. In addition, the limitation of cage material can be avoided to achieve the effect of corrosion resistance and temperature resistance of ceramic cage type all-ceramic bearing.This series of bearings is not suitable for high speed, the installation should pay attention to the notched surface installed in the end does not bear the axial load.

Hybrid

Ceramic ball especially silicon nitride ball has the characteristics of low density, high hardness, low friction coefficient, wear resistance, self-lubrication and good rigidity, especially suitable for high speed, high precision and long life mixed ceramic ball bearing rolling body (inner and outer ring is metal).Bearing steel (GCr15) or stainless steel (AISI440C) are generally used for inner and outer rings, and ZrO2, Si3N4, or SiC are available for ceramic balls

classification

Deep groove ball bearing

Deep groove ball bearings, the most representative rolling bearings, widely used, can withstand radial load and two-way axial load.Suitable for high speed rotation and low noise, low vibration or steel bearings can not be used in high temperature, cold, corrosion, magnetic field, non-insulation and other fields.

Aligning ball bearing

The raceway of the outer ring of the self-aligning ball bearing is spherical and self-aligning, which can compensate for errors caused by non-concentricity and shaft deflection.It is used for producing different core or shaft deflection parts of shaft and shell, as well as core adjustment parts required by high temperature, low cold, corrosion and non-insulation of magnetic field.Note: the inclination shall not exceed 3 degrees.

Single row angular contact ball bearings

(technical grade: P4, P5, P6, P0) angular contact bearing is suitable for high-speed and high-precision rotation, in high temperature, magnetic field, water and other does not affect its accuracy, and can withstand synthetic load.Standard of the contact Angle is 15 °, 30 °, and 40 °, the larger the contact Angle axial load capacity is larger, the smaller the contact Angle bearing can bear radial load and one-way axial load.Usually taken in pairs.Please pay attention when you buy.

Unidirectional thrust ball bearing

The one-way thrust ball bearing is composed of a washer-shaped ring with a ball rolling raceway and a cage assembled with the ball.It can bear axial load, but not radial load.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730