What are the operating principles of ceramic assembly machining

The machining of ceramic modules has great advantages compared with manual machining. For example, the ceramic modules produced by CNC machining are very accurate and repeatable.

Ceramic assembly machining can produce ceramic assemblies with complex shapes that cannot be processed manually.

How much do you know about the operating principles of ceramic assembly machining?

Let's study together.

1. the ceramic component numerical control equipment use environment.

In order to improve the service life of CNC equipment ceramic components, the general requirements to avoid direct sunlight and other thermal radiation, to avoid too wet, dust too much or corrosive gas place.

Precision ceramic components CNC equipment to stay away from large vibration equipment, such as punch, forging equipment.

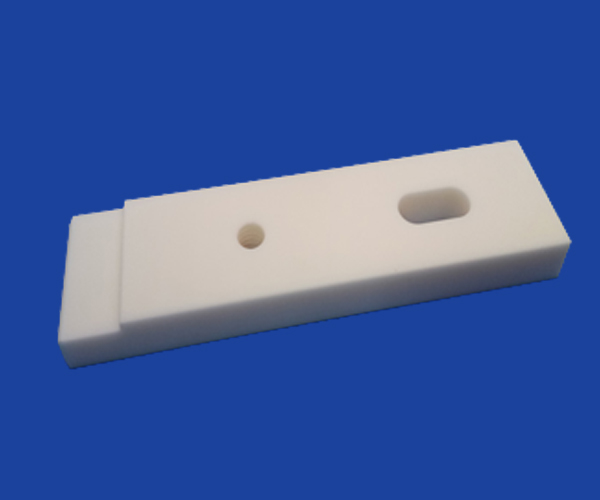

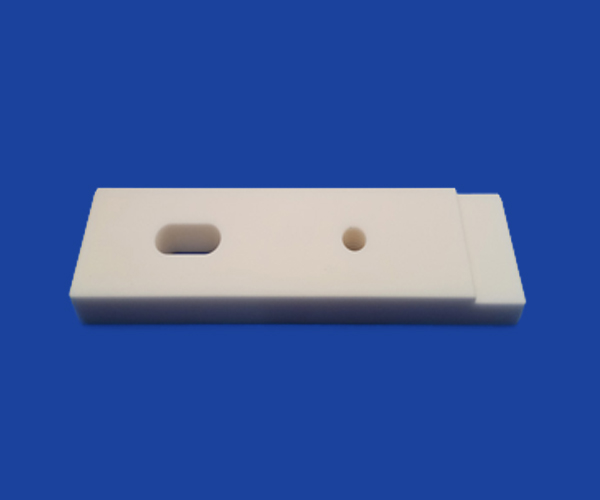

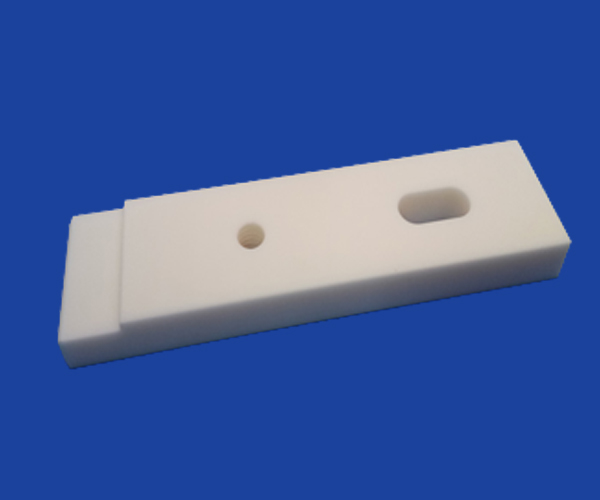

Ceramic components

2. Good power supply guarantee.

In order to avoid the influence of large power fluctuation range (more than ±10%) and possible instantaneous interference signals, CNC machining equipment of mechanical ceramic components generally adopts special line power supply (such as separate one way from the low-voltage distribution room for the use of CNC machine tools) or add voltage stabilizing device, etc., which can reduce the influence of power supply quality and electrical interference.

Formulate effective operation procedures.

In the use and management of CNC ceramic assembly machine tools, a series of practical and effective operating procedures should be developed.

For example, lubrication, maintenance, reasonable use and standardized succession system are the main contents of the use and management of CNC ceramic component equipment.

It is one of the important measures to ensure the safe operation of NC machine tools to formulate and abide by the machining operation rules of ceramic components.

Practice has shown that many failures can be reduced by following operating procedures.

As is known to all, correct operation and maintenance is one of the key factors for the correct use of ceramic module processing equipment. Correct operation can prevent abnormal wear of ceramic module machine tool and avoid sudden failure.

Daily maintenance, equipment to maintain good technical status, delay the process of deterioration, timely detection and elimination of hidden trouble, always ensure safe operation.

The daily use requirements for precision parts processing enterprises to process ceramic components are as follows:

1. After starting up, it is necessary to preheat for about 10 minutes before processing;

Long - term unused machines should extend the time of preheating;

2. Check whether the oil road is smooth;

3. Put the working table and saddle in the center of the machine before shutdown (move the three-axis travel to the middle position of each axis travel);

4. Keep the machine dry and clean.

Ceramic module processing equipment is more expensive, so correct operation and maintenance can prevent abnormal wear of the machine tool, avoid sudden failure of the machine tool.

The careful maintenance of ceramic module processing can maintain the long-term stability of the machining accuracy and prolong the service life of the machine tool.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730