Fabrication and Characteristics Of Silicon Carbide Ceramic Spare Components

Time: 2020-02-28 Writer: mingrui

Fabrication and Characteristics Of Silicon Carbide Ceramic Spare Components

The properties of silicon carbide ceramic spare components are better than those of other ceramic spare parts in some industrial applications.In the market, there are many kinds of ceramic spare components, such as alumina ceramic parts, zirconia ceramic parts, silicon carbide ceramic parts.Now minrui focuses on the performance of Silicon Nitride Ceramic Components.

Silicon carbide ceramics are synthetic, what are the main methods?

1. Acheson method:

this is the most widely used synthesis method in industry, which is prepared by heating the mixture of quartz sand and coke to 2500℃ or so by high temperature reaction.Because quartz sand and coke usually contain impurities such as Al and Fe, there is a small amount of impurities in the solid solution of SiC.Among them, impurities less green, impurities more black.

2. Chemical process:

at a certain temperature, the high purity silicon and carbon black react directly.High - purity SiC powder can be synthesized.

3. Thermal decomposition:

the decomposition of organosilicone polymers such as polycarbosilane or trichloromethylsilicon occurs in the temperature range of 1200-1500℃, from which the sub-micron level of na-sic powder is prepared.

4.Gas inverse phase method: silica tetrachloride, silicon tetrahydride and other silicone-containing gases and methane, propane and other carbon-containing gases react at high temperature to prepare nanoscale na-sic ultrafine powder.

Among them, Acheson method is the most common one in actual industrial production.

The chemical stability of silicon carbide is closely related to its oxidation properties.Silicon carbide itself is easy to oxidize, but it oxidizes to form a thin film of silicon dioxide, gradually hindering the oxidation process.

In the air, silicon carbide begins to oxidize at 800℃, but very slowly.As the temperature rises, the rate of oxidation accelerates rapidly.Silicon carbide oxidizes 1.6 times faster in oxygen than in air, slowing down over time.A typical parabolic pattern can be obtained if a quantitative trace of oxidation is made over time, which reflects the effect of the protective layer of silica on the oxidation rate of silicon carbide.

What are the main application of silicon carbide ceramics?

1. Abrasives:

because of the super rigid energy, can be prepared into various grinding wheels, gauze and other kinds of abrasives, widely used in the mechanical processing industry.

Refractory: refractory black silicon carbide is usually divided into three types.

A. Advanced refractory black silicon carbide.

B, secondary refractory black silicon carbide, containing more than 90% silicon carbide.

C. Low-priced refractory black silicon carbide, whose silicon carbide content is required to be more than 83%, is mainly used for lining of iron trough, iron water bag, zinc smelting industry and sponge manufacturing industry.

2.Deoxidizer:

compared with ferrosilicon deoxidizer, silicon carbide deoxidizer produces better steel quality and is more economical.

3. Wear-resistant and high-temperature parts:

due to the wear resistance and acid-base corrosion resistance of silicon carbide ceramics, mechanical sealing materials can be prepared, and the high thermal conductivity of silicon carbide ceramics can be used for high-temperature heat exchangers in metallurgical industry pit furnaces, etc.

4. Electrical and electrical aspects:

silicon carbide high thermal conductivity, good insulation can be used as a large scale circuit substrate and packaging materials.

Characteristics of silicon carbide porous ceramic materials

Silicon carbide porous ceramic materials are made from corundum sand, silicon carbide, cordierite and other raw materials through forming and special high temperature sintering process.

It has the advantages of high temperature resistance, high pressure, acid, alkali and organic medium corrosion resistance, good biological inertness, controllable pore structure, high open porosity, long service life, good product regeneration performance, etc. It can be applied to precise filtration and separation of various media, high pressure gas exhaust noise reduction, gas distribution and electrolytic diaphragm, etc.

Silicon carbide porous ceramic materials have the following characteristics

(1) High porosity:

an important feature of porous silicon carbide ceramics is that they have more uniform and controllable pores.Stomata are divided into open stomata and closed stomata: the open stomata can filter, absorb, absorb and eliminate the echo, while the closed stomata can help to block the transfer of heat, sound and liquid and solid particles.

(2) High strength:

porous ceramic materials are generally made of metal oxide, silicon dioxide, silicon carbide and other materials after calcination at high temperature. These materials themselves have high strength. During the calcination process, the boundaries of raw material particles melt and bond, forming ceramics with high strength.

(3) Stable physical and chemical properties:

silicon carbide porous ceramic materials can withstand acid and alkali corrosion, but also can withstand high temperature and high pressure, its own clean state is good, will not cause secondary pollution, is a kind of green environmental protection functional materials;

(4) High filtration precision, good regeneration performance:

used for filter material of porous ceramic material has a narrow pore size distribution and higher porosity and specific surface area, good contact with filtered and ceramic material, including suspended solids, colloid content and microbial pollution is intercepted in the filter medium surface or internal, filtering effect is good.After a period of use, the silicon carbide porous ceramic filter material can be backwashed with gas or liquid to restore the original filtration capacity.

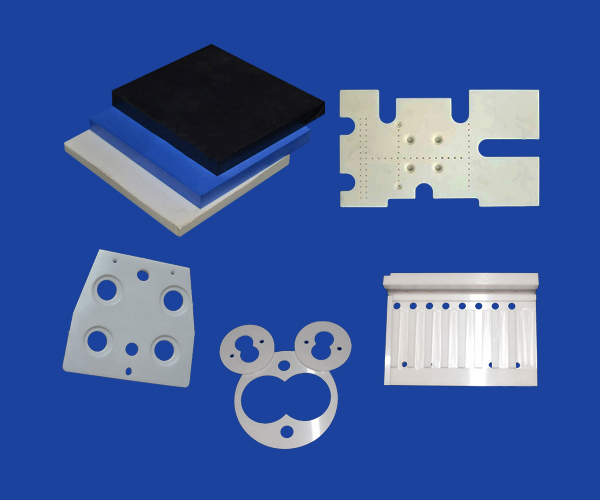

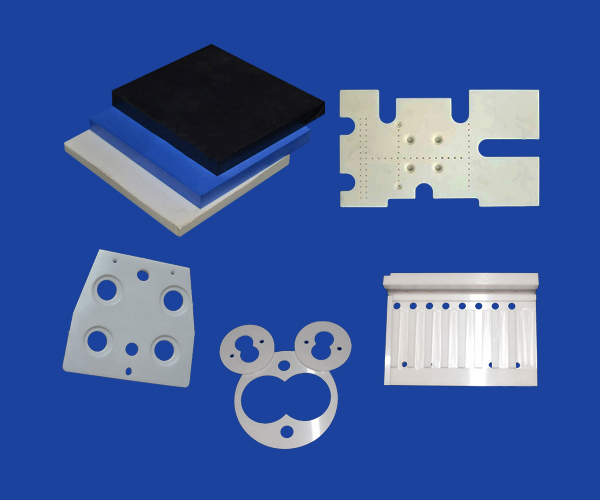

Silicon nitride ceramic components products

Silicon nitride ceramics have very good impact resistance, so many car ball bearings are made of silicon nitride ceramics.They are much harder than metal bearings and have less contact with the bearing tracks.

Because silicon nitride ceramic material has very good thermal stability and wear resistance, so good cutting tools are made of it.Compared to some metal tools, si3n4 ceramic tools have greater fracture toughness and resistance to heat and impact. They can easily cut cast iron, hard steel, and nickel-based alloys.

Silicon nitride ceramics can also be used to make insulators and chemical barriers in integrated circuits.It is much better than silicon dioxide and ACTS as a better diffusion barrier to water molecules and sodium ions.If it is a high-quality electronic product, the metropolis USES it to make relevant materials.

Silicon nitride ceramic material has high thermal stability, strong oxidation resistance and high dimensional accuracy.Because of the silicon nitride is the covalent compound high bond strength, and oxide film formed in the air, and so also has good chemical stability, oxidation under 1200 ℃, 1200 ~ 1600 ℃ generated protective film to prevent further oxidation, and is not aluminum, lead, tin, silver, brass, nickel and so on many kinds of molten metal or alloy by infiltration or corrosion, but can be magnesium, nickel chromium alloy, such as stainless steel liquid and the corrosion.

Silicon nitride ceramic material can be used in high temperature engineering components, metallurgical industry and other aspects of advanced refractory, chemical industry corrosion resistance components and sealing components, machining industry tools and cutting tools.

Because silicon nitride and silicon carbide, aluminum oxide, thorium dioxide, boron nitride and other can form a strong combination, so it can be used as a binding material, with different ratios of modification.

Application of silicon nitride ceramics in mechanical engineering

Silicon nitride is one of the hardest substances in the world because of its high strength, especially hot pressed silicon nitride.It is extremely resistant to high temperature, the strength has been able to maintain to 1200℃ high temperature without falling, will not melt into the melting body after being heated, until 1900℃ will decompose, and has amazing chemical corrosion resistance, can withstand almost all inorganic acid and less than 30% of caustic soda solution, but also can withstand a lot of organic acid corrosion;It is also a kind of high performance electrical insulating material.My application in the field of mechanical engineering:

Silicon nitride ceramic friction coefficient is small, has the self-lubricity, the strength is high, the thermal expansion coefficient is small, the volume suffers the temperature change small, effectively prevents the ball/the sealing ring to stick, may make the bearing ball ball and the mechanical sealing ring.

Silicon nitride strength, can be used in bearing manufacturing, can withstand harsh working conditions, working life is higher than the general bearing, but the production cost is also relatively high.

The traditional valve is a metal material, due to the limitation of the metal material itself, the corrosion damage of metal has a considerable impact on the wear resistance, reliability and service life of the valve;Some metal valves used in the oil industry are vulnerable to chemical corrosion, rendering them inoperable.And silicon nitride ceramics excellent corrosion resistance, wear resistance, high temperature resistance, can be qualified for this field.

Si3n4 is wear-resistant and heat-resistant, it is used as steam nozzle, no obvious damage after half year operation in boiler at 800℃.Other heat resistant alloy nozzles can only be used for 1-2 months under the same conditions.

In addition, the crushing blade made of silicon nitride material is also widely used in food processing, which can minimize impurities and contaminate food, and the blade has good durability.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730