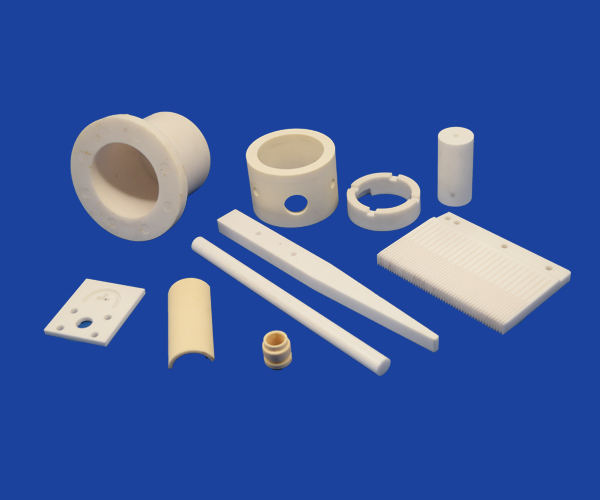

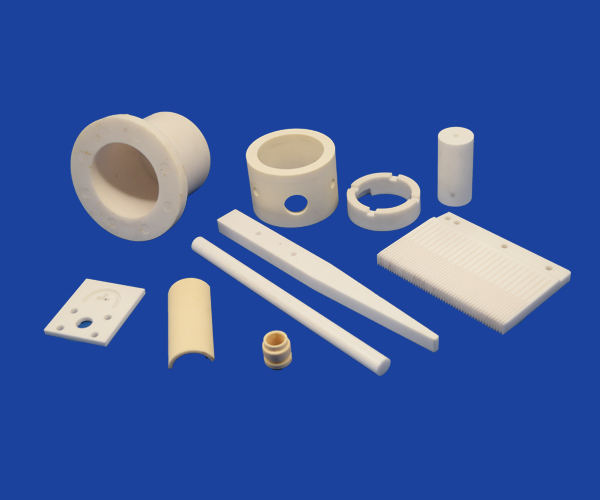

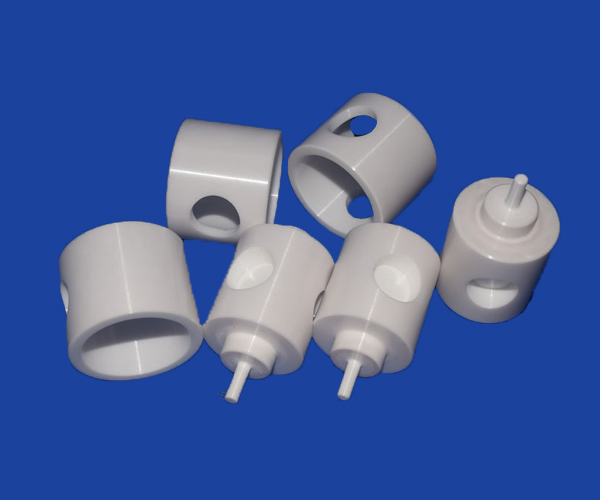

Type And Function Of Ceramic Injection Parts

Time: 2019-04-03 Writer: mingrui

Injection molding is a method of molding industrial products.The products are usually made of rubber and plastic injection moulding.Injection molding can also be divided into injection molding molding molding and die-casting method.Injection molding machine (referred to as injection machine or injection molding machine) is the main molding equipment to use thermoplastics or thermosetting materials to make plastic products of various shapes with plastic molding molds.

Injection parts: rubber parts or plastic parts

一. molding ceramic injection parts

Ceramic injection cavity: a concave part on the surface of a molded part.

Cavity plate: a plate-like part having a concave contour on the surface of a face-shaped plastic part.The fixed mold part is called the fixed mold cavity plate.The moving mold part is called the moving mold cavity plate.

Ceramic injection core: a convex part on the inner surface of a molded part.

Ceramic injection molding side core: formed parts of the plastic part side hole, side concave or side boss, can be manually or with the slider in the mold for extraction and reset movement of the core.

Ceramic injection molding insert: when the die or core has parts that are easy to be damaged or difficult to be processed as a whole, it shall be manufactured separately from the main part and embedded into the partial formed parts of the main part.

Ceramic injection molding movable insert: according to the requirements of technology and structure, it must be moulded together with the plastic part to be separated from the plastic part.

Ceramic injection molding block: it is used for assembling a certain number of separately manufactured forming parts for forming a concave mold or a mold core, which can be called concave mold block and mold core block respectively.

Ceramic injection thread cores: formed parts with internal threads of molded parts, may be movable thread cores (out of the mold) or threaded cores that rotate and move within the mold.

Ceramic injection-moulded thread rings: formed parts with external threads of molded parts, may be either movable thread rings (integral or jointed) or threaded rings rotating in a mold.

二, guide ceramic injection parts

Ceramic injection guide column: cylindrical part with guide sleeve (or hole) mounted on the other half of the mold to ensure the precision of moving mold opening and closing.There are two kinds of lead post and shoulder guide post.

Ceramic injection guide: sliding fit with guide sleeve (or hole) of push plate, two kinds of cylinder for motion guide of ejection mechanism.

Ceramic injection guide sleeve: with the guide column installed on the other half of the mold, to ensure the relative position of the moving mold and the fixed mold, to ensure the movement of the mold opening and closing precision of the circular sleeve parts.There are two kinds of lead sleeve and lead sleeve.

Ceramic injection push and pull guide sleeve: fixed on the push plate, sliding with the push plate guide column, used for motion guide circular sleeve parts of the demoulding mechanism.

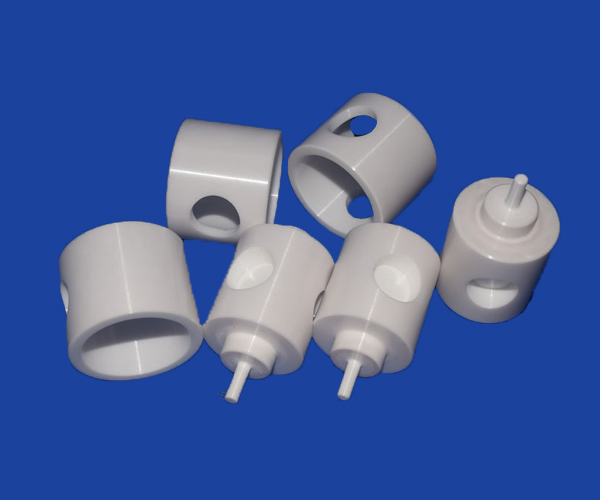

三, the introduction of ceramic injection parts

Ceramic injection molding push rod: directly push the plastic parts or pour system coagulant rod, cylindrical head push rod, with shoulder push rod and flat head push rod.Cylindrical head push rod can be used to push the top push the roof, also known as pre-bar.

Ceramic injection push tube: a tubular part that directly pushes out the plastic part.

Ceramic injection molding push plate: directly push out the plastic parts of the plate.

Ceramic injection-molded push ring: a ring or disc part that partially or wholly pushes out a plastic part.

Ceramic injection-molded push rod fixing plate: a plate-shaped part for fixing and resetting parts and pushing plate guide sleeve.

Ceramic injection-molded push rod: a plate that supports the ejection and resetting parts and directly transfers the ejection force of the machine tool.

Ceramic injection molding connecting push rod: connecting the push plate with the push plate fixed plate, transferring the thrust rod.

Ceramic injection molding pulling rod: it is set directly opposite the main flow path, with special head shape, which can pull out the bar part of the main flow path coagulant. The head shape includes Z shape, ball head shape, inverted cone shape, mushroom shape and conical head shape, etc.

Ceramic injection push runner plate: with the mold movement, to push out the casting system of the condensate plate.Also known as push plate.

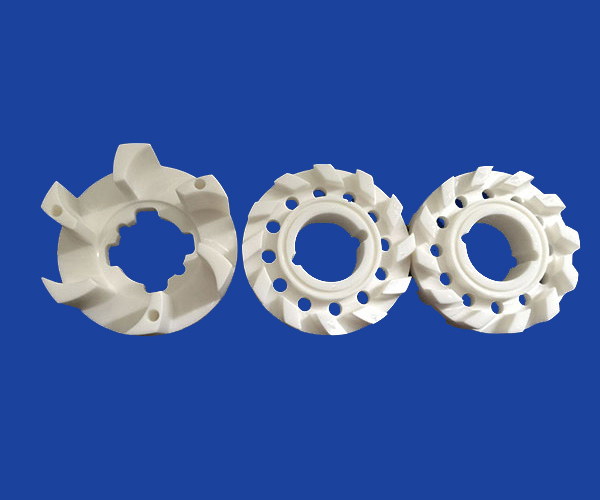

四. Core pulling (parting) ceramic parts

Ceramic bevel pin (bevel guide post) : cylindrical part that is inclined to the parting surface for assembly, so that the sliding block (or die block) reciprocates in the mold with the opening and closing of the mold.

Ceramic sliders: parts and components that move along the guiding structure and drive the side core (or die block) to complete core pulling and reset action.

Ceramic side core slide block: side core or slide block made of integral material.Sometimes several sliders form a mold block, which needs to be separated before the plastic parts can be successfully demoulded.

Ceramic slide guide: the slide guide surface of the slide is matched with the slide guide, which plays the role of slide guide.

Wedge block: part with bevel Angle used to lock the slide block during die closing.

Ceramic bending pin: with the opening and closing of the mold, the slider is used as the bending part of the rectangular or square section of the core pulling and resetting movement.

Bevel slider: a concave die block that slides by the cooperation of the bevel surface and the die sleeve and has the functions of forming, pushing out and core-pulling (parting).

Ceramic chute guide plate: with the chute, with the opening and closing of the mold, so that the slider with the chute for the core and reset movement of the plate-like parts.

五, support fixed ceramic parts

Positioning plate: the choice of fixing the fixed plate on the fixed worktable surface of the injection machine.

Movable mold base plate: the plate that makes the movable mold be fixed on the movable working table of the injection machine.

Die fixing plate: a plate-like part for fixing a concave plate (cavity), also called cavity fixing plate.

Core fixing plate: a plate part of a fixed core.

Ceramic mold bushing: a frame-bushing structural part that positions and fastens inserts or blocks together, or a frame-bushing part that secures a die or core.

Support plate: plate that prevents axial displacement of formed parts (die, core or insert) and guide parts and bears the forming pressure.

Pad block: a block part that adjusts the height of the mould closure to form the ejection space required by the ejection mechanism.

Support: adjust the closing height of the mold to form the push travel space required by the demoulding mechanism, and fix the moving mold on the "L" shaped block parts of the injection machine, also known as the mold foot.

Supporting column: column-shaped parts which are arranged between the supporting plate and the supporting plate to enhance the stiffness of the supporting plate.

六.Positioning and limiting parts

Ceramic locating ring: a circular or circular plate-shaped part that aligns the mold mainstream channel with the nozzle of the injection machine and determines the installation position of the mold on the injection machine.

Ceramic conical position-fixing part: it is the part accurately positioned by using the corresponding matching conical surface when the mold is closed.

Ceramic reset bar: the bar that is fixed on the fixed plate of the push bar and makes the demoulding mechanism reset by virtue of the closing action of the mold.

Limit pin: it can support and adjust the demolding mechanism, and prevent the parts affected by foreign objects in the resetting of the demolding mechanism, or bar parts that limit the final position of the sliding block core pulling.

Fixed distance pull rod: a rod used to limit the pulling or stopping action of a template within a limited distance during mold parting.

Locating pin: cylindrical member that secures two or more forms in position to prevent displacement.

Fixed distance pull plate: plate used to limit a certain template to open or stop action within a limited distance in the case of mold parting.

七,Cooling and heating ceramic parts

Ceramic cooling nozzles: used for connecting rubber pipes and pouring cold water into the mold.

Ceramic separator: a metal strip or plate arranged in the cooling water passage of a mold to change the flow direction of cooling water

Ceramic heating plate: set by hot water (oil), steam or electric heating elements and other plates with heating structure, to ensure that the mold temperature meets the requirements of plastic forming process.

Ceramic heat shield: a plate that prevents heat transfer and diffusion.

八, other

Ceramic gate: a bushing part with a main flow passage in direct contact with the injector nozzle.

Ceramic sprue insert: to improve the service life of the sprue, wear-resistant metal insert is used for the sprue.

Ceramic runner plate: a specially set plate for opening the diverter, which can be divided into hot runner plate and warm runner plate.

Ceramic secondary nozzles: nozzles providing direct or indirect feeding passage from the hot runner plate (column) to the mold cavity.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730