Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730

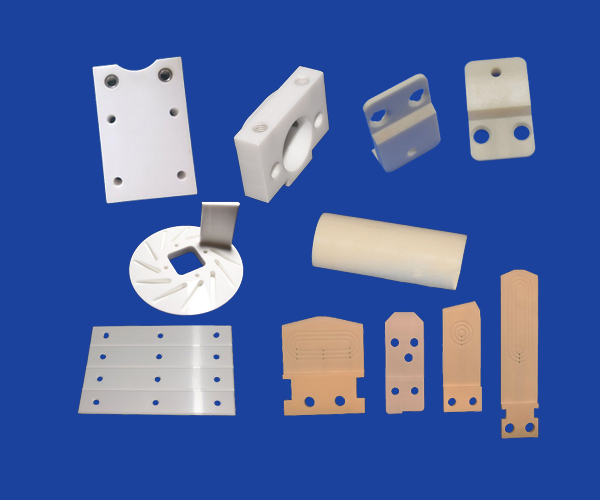

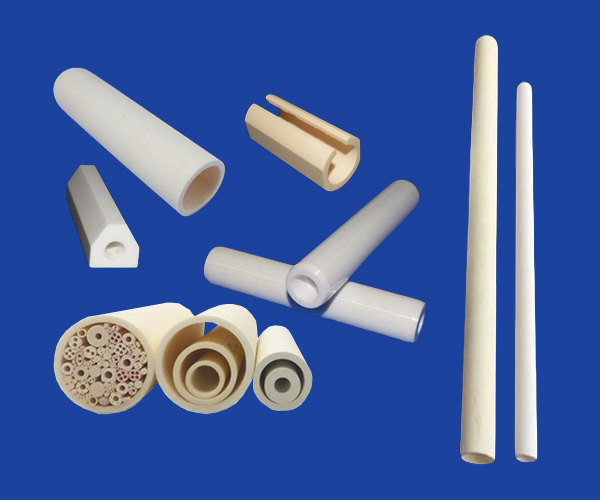

The ceramic processing center is suitable for the ceramic parts which can be processed with complex, multi-procedure, high requirement, need many types of common machine tools and many cutting tools and fixtures, and can be finished after many times of clamping and adjustment.The main objects of its ceramic processing are five categories: ceramic box parts, ceramic complex curved surface, ceramic abnormals, ceramic disc plate ceramic parts and special ceramic processing.

(1) Ceramic box parts

Ceramic box parts generally refers to a more than one hole system, the internal cavity, in the long, wide, high direction of a certain proportion of parts.This kind of ceramic parts are widely used in machine tools, automobile, aircraft manufacturing and other industries.Ceramic body parts need to be more commonly location hole and surface processing, the tolerance demand is higher, especially the form tolerance is strict, usually after milling, drilling, expanding, boring, reaming, economic, tapping process, such as need cutting tool is more, on the machine in normal difficulty big, tooling is decreasing, the high cost, processing cycle is long, need many times the clamping, alignment, manual measurement more, must be frequently replaced when the processing, the process is difficult to develop, more important is hard to ensure accuracy.

Machining center for ceramic box parts, when the machining station is more, the need for the rotation Angle of the table to complete the parts, generally choose horizontal boring and milling type machining center.When the processing station is less, and the span is not big, can choose the vertical machining center, from one end of the processing.

(2) Complex ceramic surface

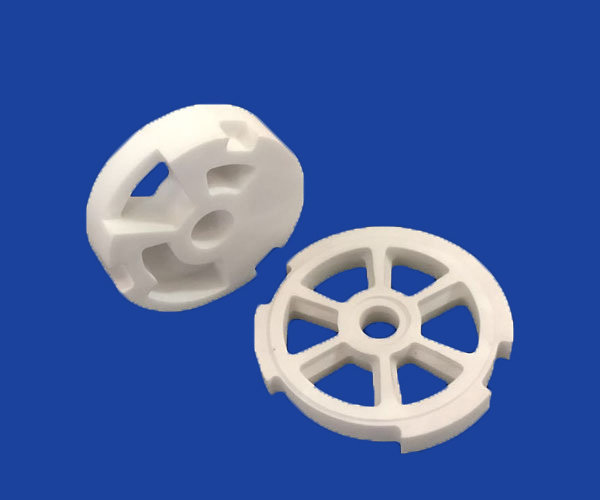

Ceramic complex surface plays a particularly important role in machinery manufacturing, especially in aerospace industry.It is difficult or even impossible to finish the complicated surface of ceramics by ordinary machining.In China, the traditional method is precision casting, so it is conceivable that its precision is low.Ceramic complex surface components such as: various ceramic impeller, ceramic wind turbine, ceramic sphere, various surface forming mold, propeller and underwater vehicle propeller, and some other shape of free-form surface.This kind of ceramic parts can be processed in a machining center.Typical ones are as follows:

1.CAM, CAM mechanism

As the basic element of mechanical information storage and transmission, it is widely used in all kinds of automatic machines.It has all kinds of curved disk cams, cylindrical cams, conical cams, bucket cams, end cams and so on.Processing this kind of parts can be selected according to the complexity of the CAM three axis, four axis linkage or the selection of five axis linkage machining center.

2. Integral impeller type

This kind of parts are common in aero-engine compressor, oxygen production equipment expansion machine, single screw air compressor, etc., for such a profile, can be used more than four axis linkage machining center to complete.

(3) the mold class

Such as injection mold, rubber mold, vacuum forming blister mold, refrigerator foam mold, pressure casting mold, precision casting mold, etc.Using machining center to process molds, due to the highly concentrated process, the precision machining of critical parts such as moving mold and static mold is basically completed in one installation, which can reduce the size of the cumulative error, reduce the workload of repair.At the same time, the mold has good reproducibility and interchangeability.Machining residual to the fitter's workload is small, where the tool can be, as far as possible by machining, so that the die fitter's workload mainly depends on polishing.

(4) spherical

Machining center milling can be used.Three-axis milling can only use ball end milling cutter as the approximate machining, the efficiency is low, five-axis milling can use end milling cutter as the enveloping surface to approximate the sphere.Complex surface machining center processing, programming workload is large, most of the need for automatic programming technology.

(3) Special-shaped ceramic pieces

Ceramic abnormity parts are irregular ceramic parts, most of which need multi-station mixed processing of point, line and surface.The rigidity of special-shaped ceramic parts is generally poor, the clamping deformation is difficult to control, the machining accuracy is difficult to ensure, and even some ceramic parts of some machining parts with ordinary machine tools is difficult to complete.The ceramic processing center should adopt reasonable technological measures, one or two clamping, the use of the processing center multi-station point, line, surface mixed processing characteristics, to complete the multi-process or all the process content.

(4) Plate, cover and plate ceramic parts

With keyway, or radial hole, or the end of the distribution of the hole system, curved disk or shaft parts, such as with flange shaft sleeve, with keyway or square shaft parts, etc., there are more porous processing plate parts, such as all kinds of motor cover, etc.It is advisable to choose vertical machining center for disk parts with distributed hole system and curved surface, and horizontal machining center with radial hole.

(5) Special processing

After mastering the functions of the machining center, with certain tooling and special tools, the machining center can be used to complete some special technological work, such as lettering, line cutting and pattern cutting on the metal surface.High frequency electric spark power supply is installed on the spindle of the machining center, which can quench the metal surface by line scanning.The grinding of small module involute conical gear and various curves and surfaces can be realized by installing high speed grinding head in the machining center.

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve