Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730

No matter it is automobile, communication, medical or watch, mobile phone, computer and other industries, have made considerable progress and development.So in such an industry, more must use one thing, that is precision ceramic parts.Some industries need less precision ceramic parts, some need is very much, and each industry needs more ceramic parts are different, of course, the use is not the same.Under such a big background, catalyzed precision ceramic processing, precision ceramic parts processing industry.And these years, the need for precision ceramic parts is very much, so that the rise of precision ceramic processing industry.So since there are so many precision machining enterprises, there must be some quality problems, today we will talk about how to ensure the production of qualified precision machining ceramic parts.

1, first of all, from the business units to the business, need each other to provide drawings of the precision ceramic components, and then according to the image, study and repeated proofing, this project, the company engineers will play a big role, some engineers will see drawings is basically at a glance, while some technicians see drawings have deviation, so the first step is very important, the first step to do is not good, behind more futile.

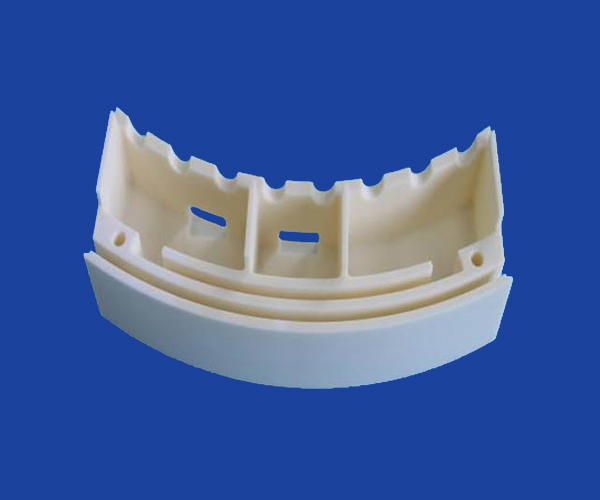

2, ceramic material, quality is not good, material is very important.Generally speaking, the materials needed for precision mechanical ceramics processing are generally zirconia, alumina, silicon nitride and so on.This does not need to grasp the quality control, otherwise it will be produced, supporting to the application of the machine, it is very easy to damage and wear.Of course, in order to reduce costs, some companies choose low prices of ceramic materials, so they are earning money, but the problems in the later period will be very big.In addition is the processing used to the cutting oil, and cutting fluid, this general quality is not much.

3, ceramic processing equipment, this link is mainly purchased CNC ceramic processing equipment, generally speaking, imported equipment processing of ceramic parts will be less deviation, low scrap rate, in addition to high productivity.Generally speaking, international equipment is a good choice nowadays.

4. Of course, no matter how good the equipment and materials are, excellent operators are also needed to operate them.Of course, this piece is best operated by staff who have been working on precision ceramic parts for years.

5. Finally, it is the quality inspection personnel. After the production of each ceramic part, the quality inspection personnel must personally inspect and test qualified before it can be fully passed.Of course, we also need to pay attention to the transportation in the future. After all, some parts made of materials are soft, and they will be damaged easily if squeezed too much. Therefore, we also need to pay attention to this part.

Basically the above five points have been done, then the production of qualified precision ceramic parts does not exist any problem.

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve