Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730

What are the processing requirements for precision ceramic parts?

For precision ceramic parts, the processing is very strict, the processing process has a knife, knife, etc.Have specific requirements for precision ceramic components size, the accuracy of precision ceramic components are required, such as how many microns of plus or minus 1 mm, if too much wrong size precision ceramic components will become a waste, at this moment is the equivalent of reprocessed, time-consuming, and sometimes even make the whole processing scrap material, this will result in an increase in the cost, at the same time, is can't use the ceramic parts.

The processing of precision ceramic parts is mainly required by dimension. For example, the diameter of the cylinder of ceramic parts is strictly required. Only qualified parts with positive and negative errors within the required range are qualified parts; otherwise, they are unqualified parts.Ceramic parts also have specific strict requirements, the dimensions of error of plus or minus also has a regulation, such as an embedded ceramic parts cylinder (take the most simple and basic parts for example), if the diameter is too large, more than the range of allowable error, will cause, don't go in, if the actual diameter is too small, more than the negative value of allowable error threshold, will cause is too loose, inserted in unstable problem.These are the products of unqualified ceramic parts, or the cylinder length is too long or too short, exceeding the allowable error range. They are all the products of unqualified ceramic parts, and they will be discarded or reprocessed, which will inevitably lead to an increase in cost.

Above is the requirement for ceramic parts processing, is the size of the main problems, must be in strict accordance with the additional drawings for processing, processing of actual size won't theory and drawing the same size, but, as long as the dimensions in the range of allowable error are qualified parts, so the ceramic parts processing requirement is in strict accordance with the theoretical size for processing.

The second is the advanced ceramic parts processing equipment and testing equipment. The advanced ceramic parts processing equipment makes the processing of precision parts simpler, more accurate and more effective.The testing equipment can detect the ceramic parts that do not meet the requirements, so that all the ceramic parts products sent to customers really meet the requirements.

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

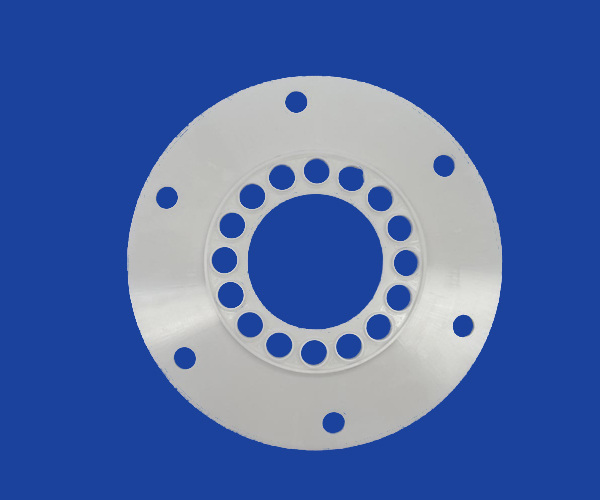

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve