Comparison of traditional gear with ceramic gear

Time: 2021-03-17 Writer: mingrui

Comparison of traditional gear with ceramic gear

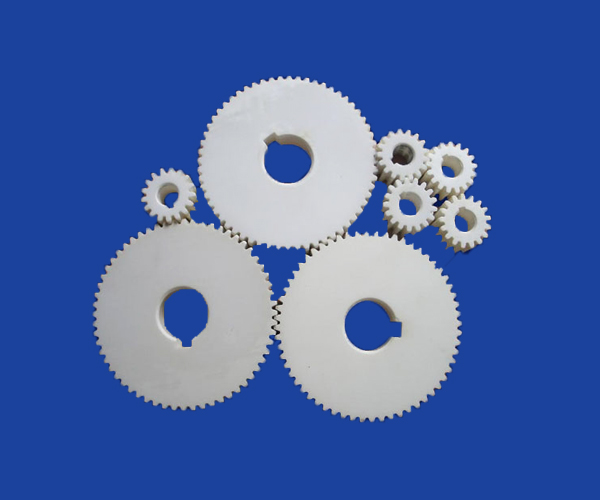

Abstract: zirconia ceramics and alumina ceramics are both wear-resistant and high-temperature ceramics, so there are many advantages in manufacturing ceramic gears with them compared with traditional gears.

Zirconia ceramics and alumina ceramics are both wear-resistant and high-temperature ceramics, so the ceramic gears produced by them have many advantages over traditional gears.

With the increasing use of gears, ceramic gears are expected to be able to withstand high temperatures, non-oil environments or dry conditions.At high temperature, the most prominent advantage of ceramic materials is the strength of stability, but also not easy to produce gluing, even in the non-oil or dry environment is also so, and has a strong ability to resist chemical corrosion.

The steels commonly used in traditional gear manufacturing are quenched and tempered steels, hardened steels, carburized and quenched steels and nitrided steels.Cast steel has a slightly lower strength than forged steel and is often used for larger gears.Gray cast iron has poor mechanical properties and can be used in light load open gear transmission.Ductile iron can partly replace steel to make gears;Plastic gear is usually used for light load and low noise requirement. Steel gear with good thermal conductivity is usually used for matched gear.Ceramic gears made of zirconia and alumina ceramics are developing towards the direction of heavy load, high speed, high precision and high efficiency.

The development of ceramic gear manufacturing technology will be to further study the mechanism of gear tooth damage, which is the basis of establishing reliable strength calculation method, and the theoretical basis of improving the bearing capacity and prolonging the service life of gear.To develop the new tooth shape represented by the arc tooth profile;Research on new ceramic gear materials and new technology for gear manufacturing;The elastic deformation, manufacturing and installation errors and temperature field distribution of ceramic gears were studied, and the ceramic gears were modified to improve the running stability of ceramic gears and increase the contact area of ceramic gears at full load, so as to improve the bearing capacity of ceramic gears.

Friction, lubrication theory and lubrication technology are the basic work of ceramic gear. Elastohydrodynamic lubrication USES synthetic lubricating oil and extreme pressure additives appropriately added in the oil, which can not only improve the bearing capacity of ceramic gear tooth surface, but also improve the transmission efficiency.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730