What is the difference between ceramic wafer and ceramic substrate?

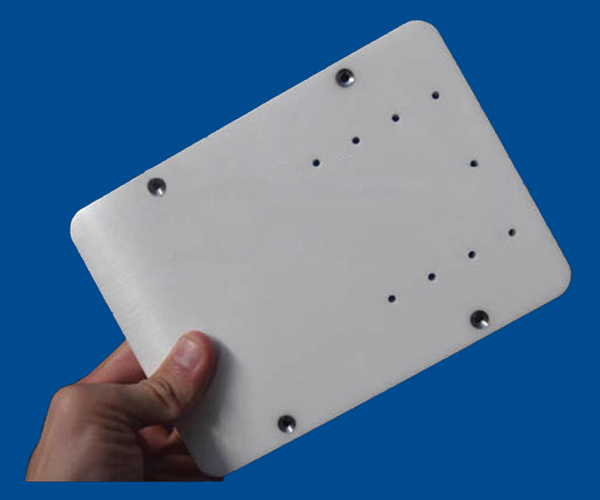

Ceramic wafer is a sheet material with electronic ceramics as the wafer to form a supporting base for film circuit elements and external fitting elements.

Ceramic substrate refers to the copper foil at high temperature directly bonded to the surface of the ceramic substrate (single or double) on the special process board.The ultra-thin composite substrate made of stone ceramic substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft soldering and high adhesion strength, and can be like PCB board can be etched out of a variety of graphics, with great current-carrying capacity.Therefore, ceramic substrate has become the basic material of high power electronic circuit structure technology and interconnection technology.

Simply put, there are no wires on the substrate, and metal wires have been etched on the substrate.

Common characteristics of ceramic wafer and ceramic substrate

Strong mechanical stress, stable shape;High strength, high thermal conductivity, high insulation;Strong adhesion and corrosion resistance.

Excellent thermal cycle performance, cycle times up to 50,000 times, high reliability.

As PCB board (or IMS substrate) can be etched out of the structure of various graphics;No pollution, no pollution.

In pieces with wide temperature - 55 ℃ ~ 850 ℃;The thermal expansion coefficient is close to that of silicon, which simplifies the production process of power module.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730