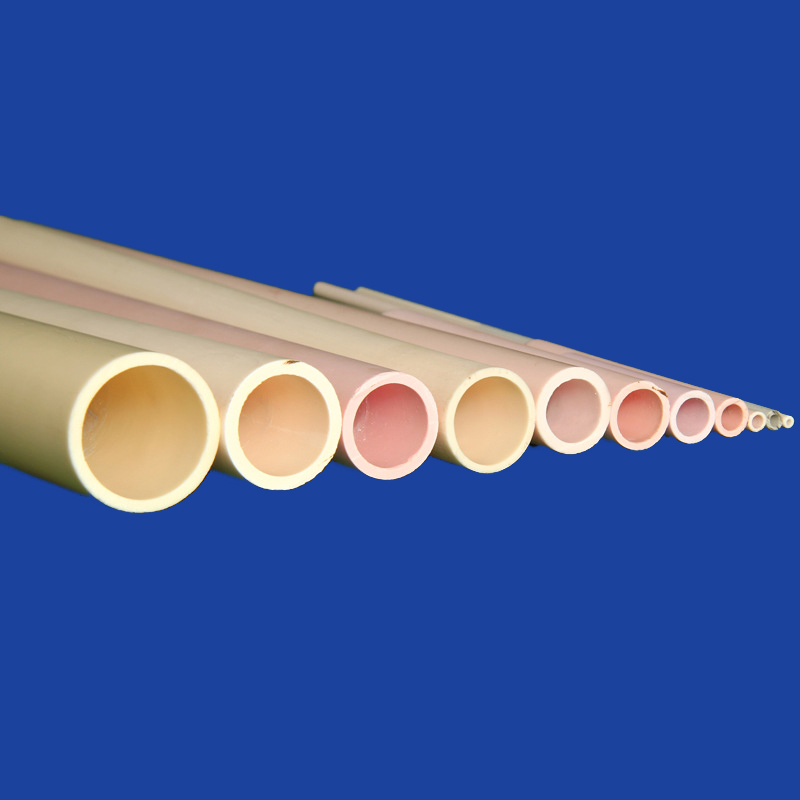

High - temperature wear - resistant ceramic tube performance and purity subdivision

Alumina high temperature wear resistant ceramic tube is a ceramic material with alumina (Al2O3) as the main body. Alumina ceramics have good conductivity, mechanical strength and high temperature resistance insulation performance.

Alumina high temperature wear resistant ceramic tube, its use is very wide, because of the superior performance of alumina material, the application in modern society has been more and more recognized and used, to meet the needs of daily use and special industrial performance.

Alumina high temperature wear resistant ceramic tube, can be roughly divided into:

There are three types of high purity aluminum oxide (high purity alumina content, e.g., more than 99%), common type (purity content, 95-99%) and low purity (purity content, below 95%).

Among them, 99 alumina ceramic materials are used for making high temperature crucibles, fireproof tubes and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve plates.

Alumina ceramics are mainly used as corrosion-resistant and wear-resisting parts.

For example, 85 porcelain is often mixed with talc to improve the electrical performance and mechanical strength, and can be sealed with molybdenum, niobium, tantalum and other metals, some used as electrical vacuum devices.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730