Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

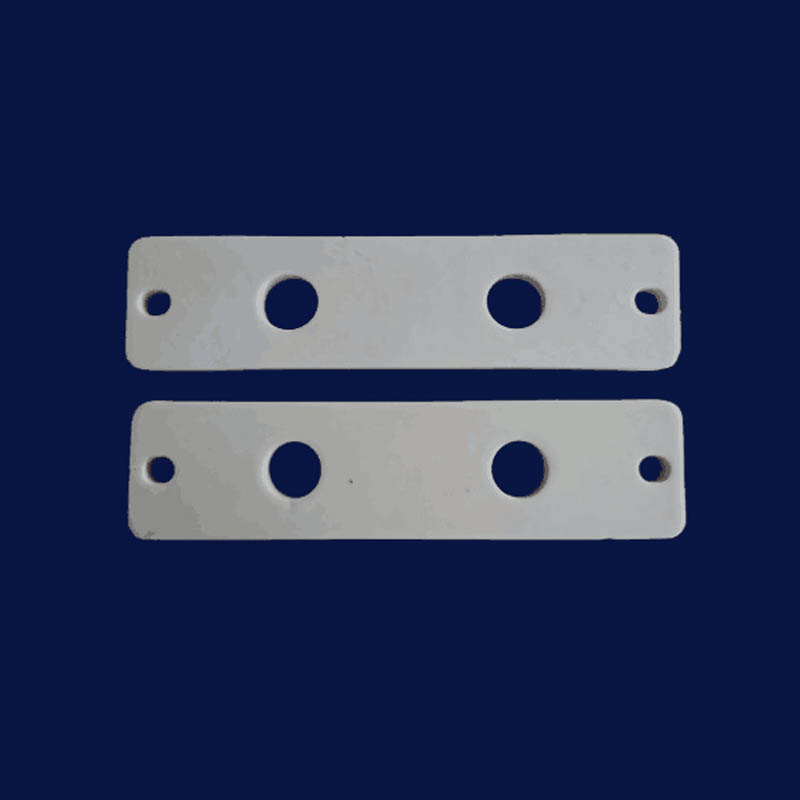

What are the requirements for processing zirconia ceramic plates?

Zirconia ceramic plate through powder forming for wool embryo, and then through ceramic processing is ceramic plate to meet customer requirements, so what processing requirements must be met in the processing?Mingrui ceramics factory gives e... 2021-01-20

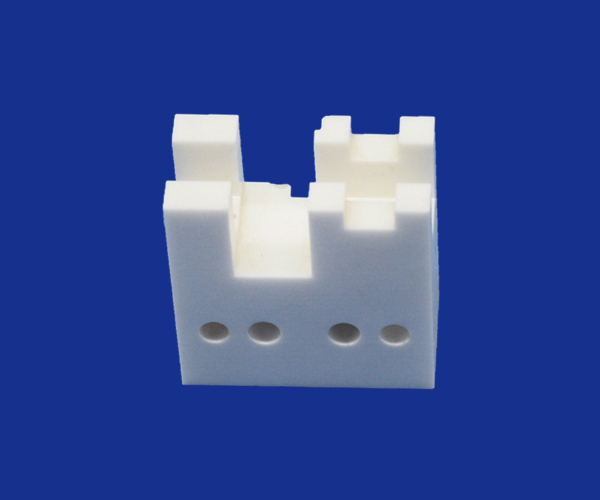

Application classification of zirconia ceramic structural parts

Application classification of zirconia ceramic structural parts Zirconia ceramic structural part is an inorganic non-metal material which is resistant to high temperature, wear and corrosion. Its melting point is as high as degree Celsius.... 2021-01-20

Comparison advantage between ceramic needle gauge and tungsten steel white steel needle gauge

Comparison advantage between ceramic needle gauge and tungsten steel white steel needle gauge When it comes to needle rules, it is necessary to explain the stamping die, needle gauge is the stamping mold work when the essential accessories,... 2021-01-20

Zirconia ceramics as thermal resistance materials in aerospace

Zirconia ceramics as thermal resistance materials in aerospace Zirconia Ceramics as a high-temperature resistant ceramics, and thermal insulation is very strong, very suitable for use as a heat resistance material, and this heat resistance... 2021-01-20

Classification standard and application of ceramic worm structure and tooth shape of ceramic worm

Classification standard and application of ceramic worm structure and tooth shape of ceramic worm... 2021-01-06

Installation of linear ceramic slide track for screw lift

Installation of linear ceramic slide track for screw lift... 2021-01-06

Abrasion of ceramic bearing on ball screw elevator and its solution

Rolling ceramic bearings are widely used in ball screw elevator.We know that the ball screw elevator rolling ceramic bearings wear out easily.Make sure that this will help you with this difficulty.... 2021-01-06

What is the tooth surface strength, bending strength of ceramic gear, how to choose?

The ceramic tooth surface strength is the friction resistance of the meshing ceramic tooth during repeated contact.... 2020-12-23Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

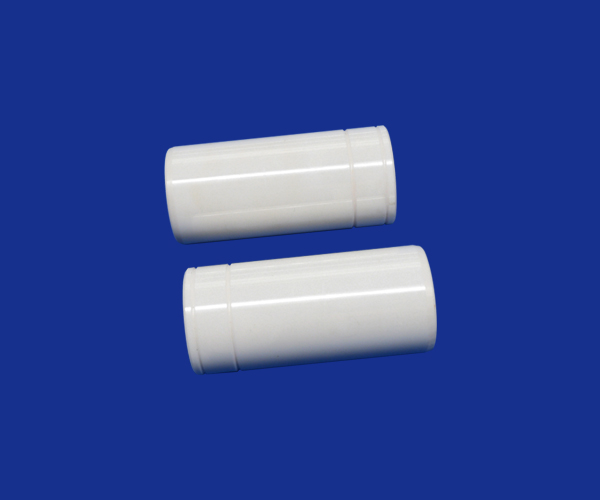

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS