|

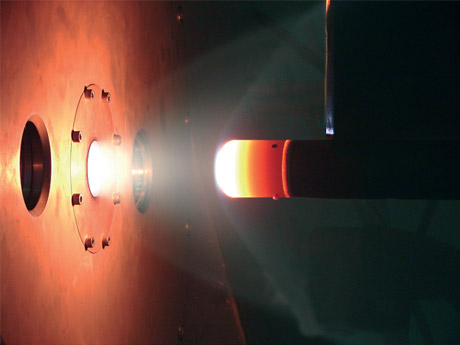

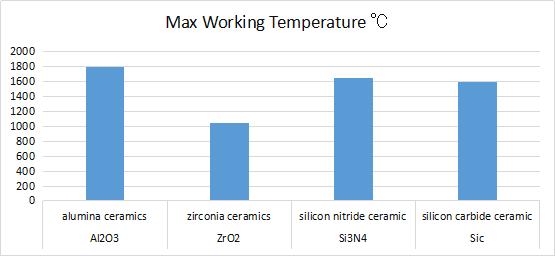

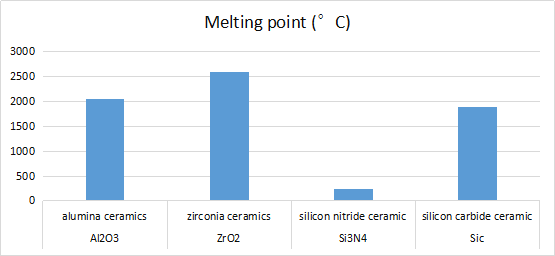

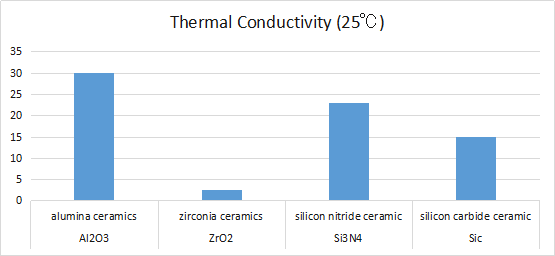

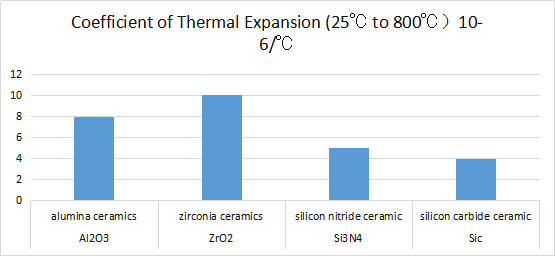

Ceramic materials generally have high melting point (mostly above 2000℃) and excellent chemical stability at high temperature.Ceramic thermal conductivity is lower than metal materials, ceramics or a good thermal insulation material.At the same time, the linear expansion coefficient of ceramics is lower than that of metals. When the temperature changes, ceramics have good dimensional stability.

As for the thermal conductivity of high temperature resistance, the higher the thermal conductivity is, the better it is in theory. With high thermal conductivity, the thermal energy conduction of ceramic parts is fast, and the internal and external temperature difference is low. |

|

|

|

|

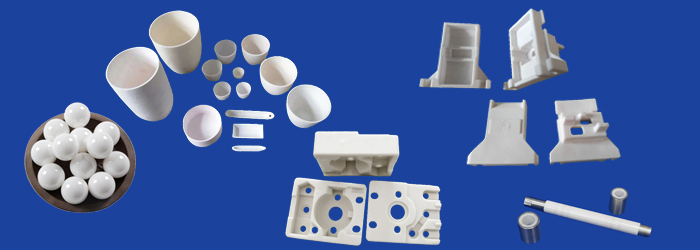

| Technical reference of manufacture | |||

| Dimensional accuracy | Up to 0.001mm | ||

| Concentricity | Up to 0.003mm | ||

| Parallelism | Up to 0.002mm | ||

| The inner hole tolerance | The minimum 0.005mm | ||

| Straight flute | The narrowest 0.1x100mm | ||

| The thickness of the size | Minimum to 0.02mm | ||

| The screw thread | Minimum internal thread M2 | ||

| Cylindricity | Up to 0.004mm | ||

| The linear tolerance | Up to 0.001mm | ||

| The smallest aperture | The minimum 0.07mm | ||

| Precision process | CNC maching,grinding,lapping | ||

| Surface finish | Glazed,polishing or metallized |

|

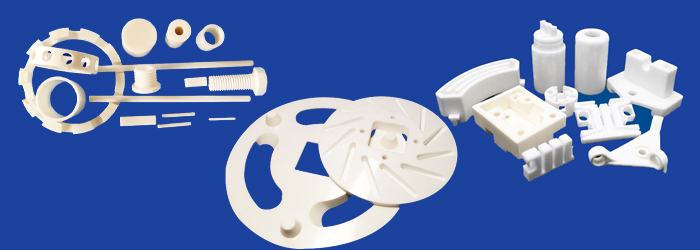

Dongguan Mingrui Ceramics Technology Co., Ltd is a professional manufacturer of ceramic structural parts. We have more than 10 senior engineers,technical backbone, more than 60 workshop technicians. We produce strengthened structure zirconia ceramic bar, ceramic tube, ceramic shaft, ceramic plate, ceramic sleeve, ceramic valve, ceramic plunger and ceramic arm. The products are applicable to instruments,medical instruments, clocks and electronic products, mills, energy and power, autocar and military and some other high-end areas. |

|

Our high temperature ceramics parts are mainly used in the industrial field of precision ceramic structural parts, ceramic materials using high-strength zirconia (yttrium stable/magnesium stable/cerium Stable), alumina (97/99/99.5/99.7/99.9/99.99) material.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information,please contact us.

CEO : Mr Admin

Dongguan Mingrui Ceramic Technology Co., Ltd.

Mobile : +86 18122974730

Tel : +86 0769-85090316-8038

E-mail : admin@cerampart.com

Website: www.cerampart.com

| For more information about high temperature ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS