Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Application of ceramic components in LED lighting

Led is a new type of solid state light source, which has attracted great attention since its appearance.Its luminescence mechanism is generated by the transition of electrons in the PN junction between energy bands.... 2019-03-05

Technical Ceramic components for photovoltaic solar industry

photovoltaic market is becoming decentralized. Fluctuations in one market may cause some fluctuations in the photovoltaic industry chain.Structural ceramics are advanced ceramics with excellent mechanical, thermal and chemical properties, su... 2019-03-05

Medical ceramic component parts for medical device

Ceramic materials are often used in medical device due to their excellent properties, such as high temperature resistance, corrosion resistance, abrasion resistance, chemical stability and so on.The market of medical device is becoming larger and larg... 2019-02-20

Guangzhou nineth International Solar Photovoltaic exhibition successfully concluded

... 2019-02-15

Wear - resistant ceramic tube features

Wear - resistant ceramic tube features ;Steel tube layer: the bend is formed by the integral hot bending of SUS304.Compared with welded elbow, it has better appearance, unobstructed airflow and pressure resistance. Wear-resisting ceramic ... 2019-02-14

Wear - resistant ceramic performance characteristics

Wear-resistant ceramics is AL2O3 as the main raw material, with rare metal oxides as the flux, the special corundum ceramics baked by 1700 baidu high temperature, and then the special rubber and high strength organic/inorganic adhesive combi... 2019-02-14

Standard for ceramic wear-resisting elbows

Ceramic elbow a device used to connect pipes.It is the most ideal material for conveying particles or corroding raw materials.Therefore, the quality of ceramic elbow must be strictly controlled, so as to avoid accidents during transportation... 2019-02-14

Wear - resistant ceramic elbow measures to reduce pipe wear

Angle is the most easy worn parts, pipeline material colliding at bend easily broken, if elbow wall wear, wear in easy to wear out or adhesive powder, affect the normal delivery of the material, and material particle breakage increase, will ... 2019-02-14Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

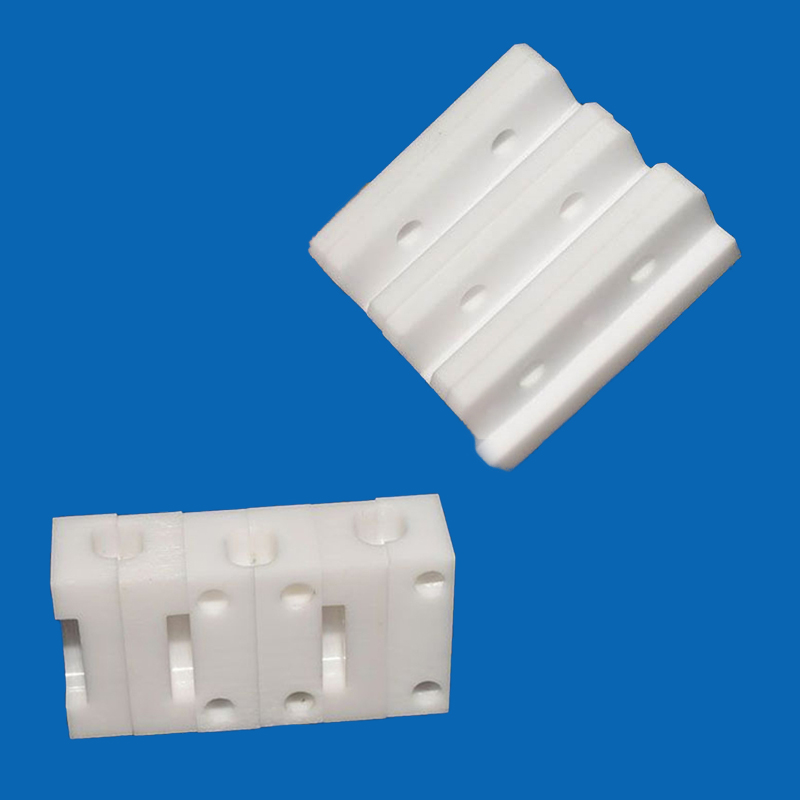

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS