Aluminum Nitride (AlN) Material Parameters |

|

|

|

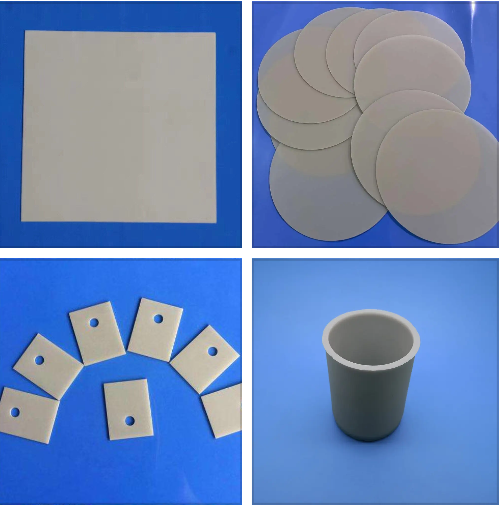

Aluminum Nitride ceramic material is an advanced ceramic material with aluminum nitride (AlN) as the main crystal phase. It has a hexagonal wurtzite crystal structure, which gives it excellent thermal conductivity and electrical insulation, making it excellent in high temperature, high power and harsh environments, and making it widely used in many high-tech and industrial fields.

Physical and chemical properties

· High thermal conductivity: The thermal conductivity is 140-180 W/(m·K), which is about 5-8 times that of aluminum oxide (Al₂O₃), close to metal aluminum, but also has electrical insulation.

· Low thermal expansion coefficient: about 4.5×10⁻⁶/°C, close to silicon (3×10⁻⁶/°C), reducing thermal stress in semiconductor packaging.

· Excellent electrical insulation: resistivity>10¹⁴ Ω·cm, stable at high temperatures.

· Chemical stability: resistant to high temperature oxidation (up to 1400℃), resistant to molten metals (such as aluminum and copper), and resistant to acid and alkali corrosion.

· Mechanical properties: high hardness (Vickers hardness of about 1200 HV) and bending strength (300-400 MPa), but low toughness (about 3 MPa·m¹/²).

|

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS