E-mail:admin@cerampart.com

Application of ZTA ceramic materials in the semiconductor industry

Time:202025-05-13

ZTA ceramic (zirconia toughened alumina ceramic) material is widely used in a variety of key areas in the semiconductor industry due to their high mechanical strength, excellent heat dissipation, electrical insulation and thermal shock resistance. The following are the main application scenarios and related technical features of ZTA ceramic materials in semiconductor applications:

1. Semiconductor device packaging substrate

ZTA ceramic substrates are widely used in the packaging of high-power semiconductor devices, such as IGBT (insulated gate bipolar transistor) modules and high-brightness LED packages for electric vehicles. Its high thermal conductivity (1.2 times higher than ordinary alumina substrates) and thermal expansion coefficient similar to silicon can effectively reduce thermal stress and improve device life and reliability. In addition, ZTA substrates are made into circuit carriers through copper cladding processes (such as DBC technology), which are suitable for power modules in high temperature and high current environments.

2. Electrostatic chuck (ESC)

Electrostatic chucks are core components in semiconductor manufacturing equipment and are used to clamp wafers in vacuum or plasma environments. ZTA ceramics are ideal materials for manufacturing dielectric layers of electrostatic chucks due to their high hardness, corrosion resistance and stable dielectric properties. Johnsen-Rahbek electrostatic chucks achieve high adsorption force at low voltage through ZTA ceramics and are widely used in processes such as etching and ion implantation.

3. Ceramic Capillary

In the semiconductor packaging process, ceramic capillary is used for wire bonding (such as gold wire and copper wire connecting chips to substrates). The high hardness, wear resistance and bending strength (up to 600MPa or more) of ZTA ceramics enable it to withstand high-frequency ultrasonic vibration and high shear stress, which is particularly suitable for copper wire welding processes and significantly reduces the risk of grain shedding. Its fine grain structure (average grain size less than 1μm) also ensures surface finish and dimensional accuracy.

4. Precision parts

ZTA ceramics are used to manufacture precision parts in the cavity of semiconductor equipment, such as bearings, guide rails, and mechanical handling arms. These parts need to work stably for a long time in high temperature, vacuum or corrosive environments. ZTA's high strength (twice as high as ordinary alumina) and thermal shock resistance (can withstand rigorous thermal shock tests) meet such needs.

5. Thermal management components

In semiconductor equipment, ZTA ceramics are used for heat dissipation components such as heat sinks and thermally conductive substrates. Its high thermal diffusion capacity and low thermal expansion coefficient can effectively manage the heat generated by the chip and avoid device failure caused by temperature fluctuations.

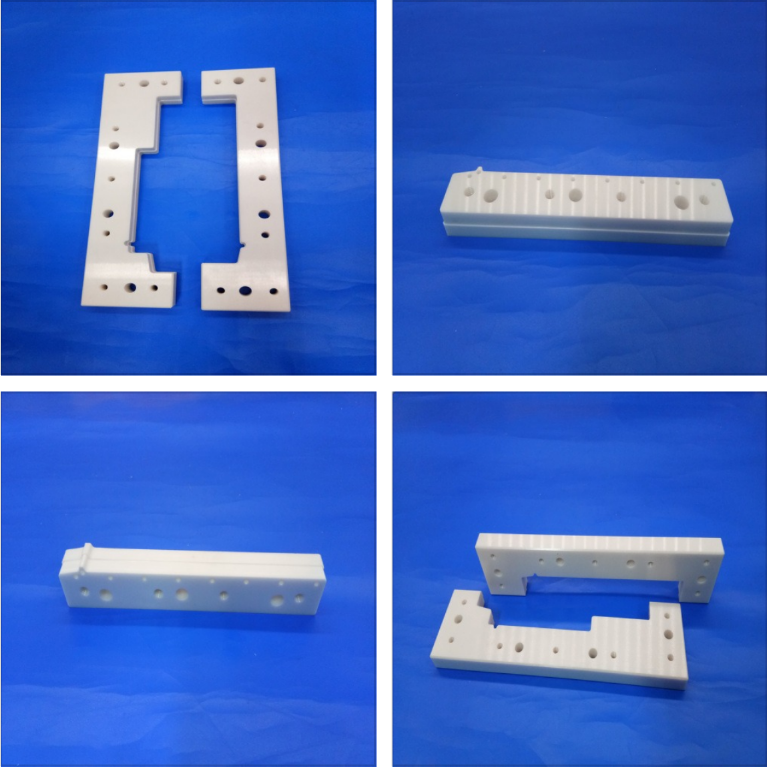

6. 3D printed customized parts

With the development of 3D printing technology, ZTA ceramics can be used to manufacture semiconductor equipment parts with complex geometries and fine structures. This customized production method can meet the semiconductor industry's demands for high-precision and high-complexity components, shorten the product development cycle, and reduce production costs.

The application of ZTA ceramics in the semiconductor industry covers the entire chain from packaging, manufacturing equipment to thermal management. Its performance advantages have promoted the technological upgrading and large-scale process of high-end semiconductor equipment.

information

- Ceramic-to-Metal Assemblies: Unlocking the Secrets

- Application Fields of Silicon Carbide Ceramics

- High-Purity Alumina Ceramics: Powering Four Major Industries

- How is the surface roughness of alumina ceramics achieved?

- What are the advantages and applications of silicon carbide c…

- Advantages of advanced ceramic materials in ceramic substrate…

- Advantages and applications of alumina ceramic tubes for furn…

- Application of ZTA ceramic materials in the semiconductor ind…

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL