E-mail:admin@cerampart.com

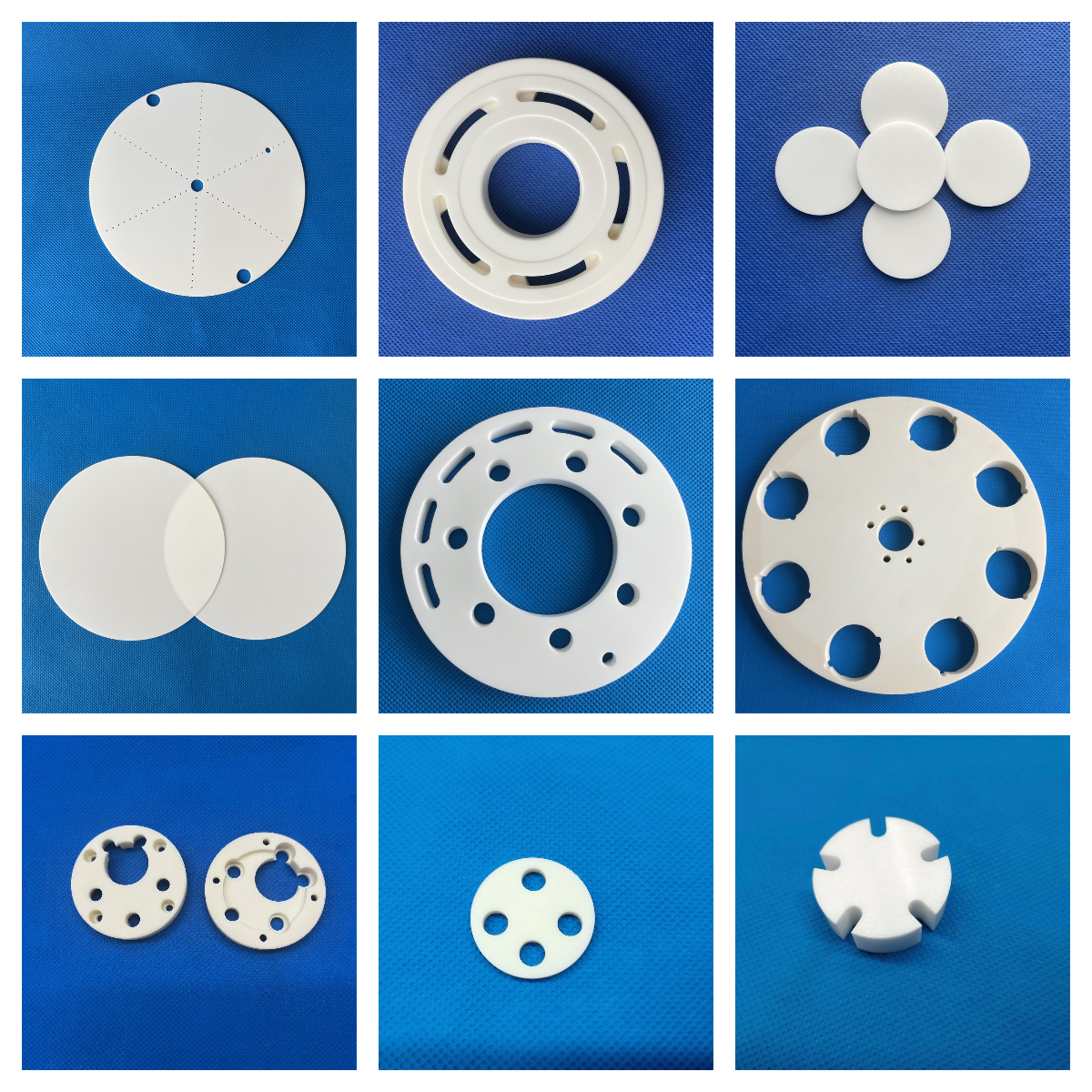

Alumina Ceramic Multihole Round Plates High Strength 95%-99.99% Alumina Ceramic Round Discs

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Alumina Ceramic Multihole Round Plates High Strength 95%-99.99% Al₂O₃ Ceramic Round Discs

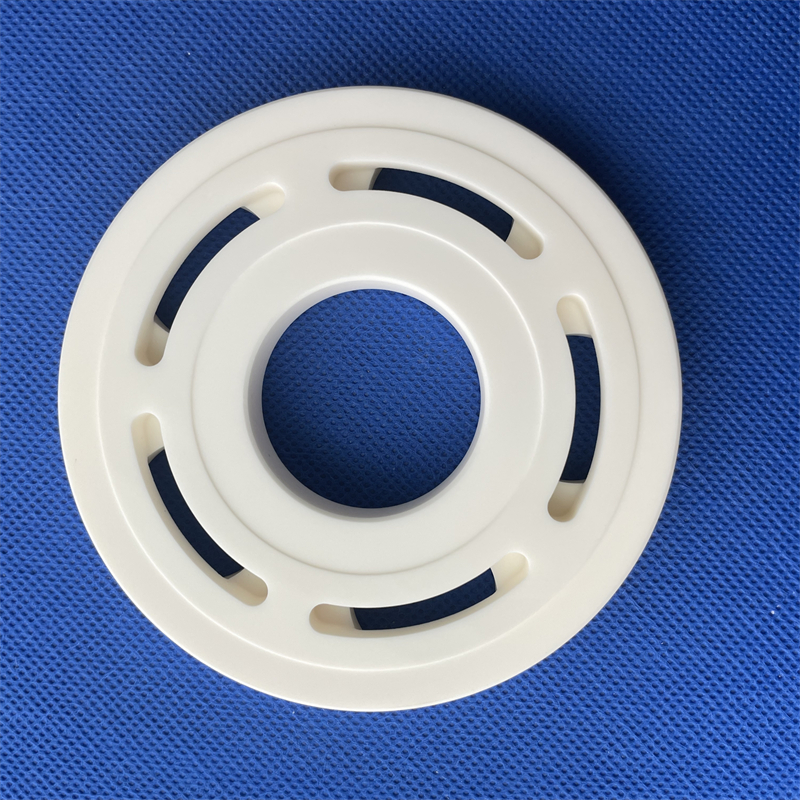

Ceramic Multihole Round Plates (Al₂O₃ Ceramic Discs) are a type of high-performance ceramic components with multihole structures and alumina (95%~99.99% Al₂O₃) as the main component. They have excellent high temperature resistance, corrosion resistance, high hardness and insulation properties, and are widely used in industry, electronics, medical and other fields.

The hardness of alumina ceramic round plates is as high as level 9, with excellent wear resistance and corrosion resistance. They can be used for a long time in harsh environments without wear. Due to the high melting point of alumina, they can work for a long time in high temperature environments without deformation, cracking or falling off, and are suitable for high-temperature industrial scenes.

In addition, alumina ceramic round plates have good electrical insulation properties, can effectively isolate the conduction of current and heat, and are suitable for the manufacture of electronic components. Low thermal expansion coefficient and good dimensional stability are suitable for occasions with high requirements for thermal stability.

alumina and zirconia ceramic discs round plates made by Mingrui Ceramic

1. Electronic industry

Alumina ceramic round plates can be used to make electronic ceramic substrates, conductive adhesives, capacitors and other electronic components to meet the needs of low high-frequency dielectric loss and excellent insulation performance.

2. Mechanical industry

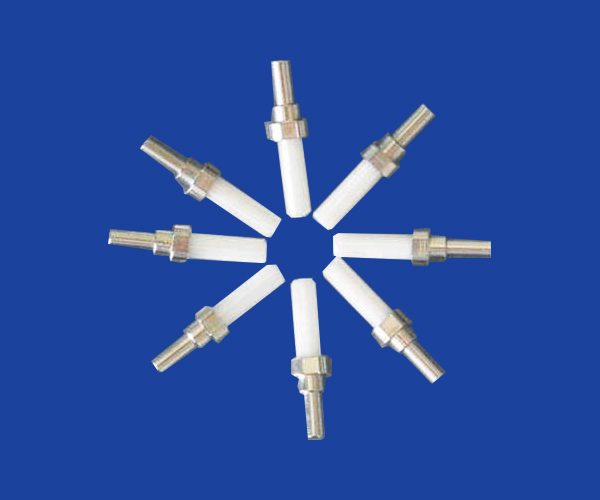

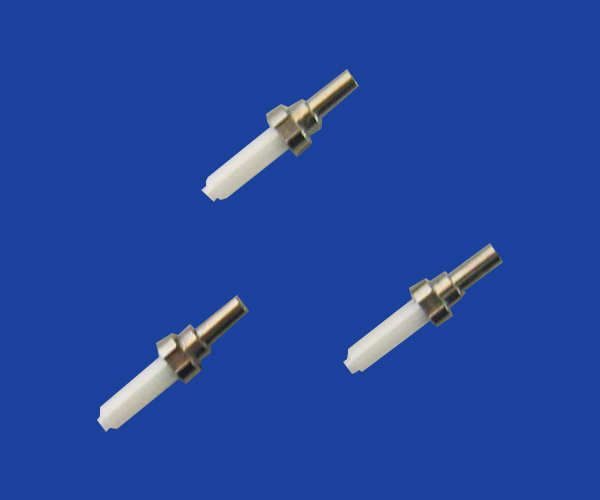

Its high hardness and wear resistance make it an ideal material for making high-wear-resistant parts such as cutting tools, bearings, and seals. It can also be used to make ceramic blades and ceramic balls.

3. Semiconductor field

In semiconductor equipment, alumina ceramic round plates are often used to make precision parts, such as etching cavities, gas nozzles, gas distribution plates, and fixed rings, etc., to meet the requirements of high precision and low expansion coefficient.

4. Biomedicine

Alumina ceramic round plates have good biocompatibility and corrosion resistance, and can be used to prepare medical devices such as artificial joints and dental restoration materials.

5. Environmental protection field

Alumina ceramic round plates can be used to make filters and catalyst carriers for purifying exhaust gas and wastewater to meet environmental protection needs.

6. New energy field

In the manufacture of key components such as fuel cells and solar cells, alumina ceramic round plates can be used for solid-state battery diaphragm materials and new energy vehicle battery module insulation parts.

Al₂O₃ Ceramic Round Plate & Disc precision process:

|

Ceramic Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic round plates&discs or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL