E-mail:admin@cerampart.com

Effect of Additives on Sintering of Alumina Ceramics

Time:202021-06-24Effect of Additives on Sintering of Alumina Ceramics

Alumina ceramics are widely used in various industries because of their many remarkable advantages, such as high hardness, high-temperature resistance, wear resistance, oxidation resistance, and so on.

Alumina ceramics are widely used in various industries because of their many remarkable advantages, such as high hardness, high-temperature resistance, wear resistance, oxidation resistance, and so on.

However, alumina has a more cationic charge, small radius, and strong ionic bond, which leads to large lattice energy, low diffusion coefficient, and high sintering temperature.

The sintering temperature of some pure alumina ceramics is above 1700 ℃. This high sintering temperature is difficult to achieve in the industry, and it is not conducive to reduce the cost.

At the same time, there are many structural shortcomings, which are not conducive to the data mechanics function of alumina ceramics.

In order to increase the density of alumina ceramics and reduce the sintering temperature, some additives will be introduced into the raw materials to reduce the sintering temperature or improve the performance of the sintering machine.

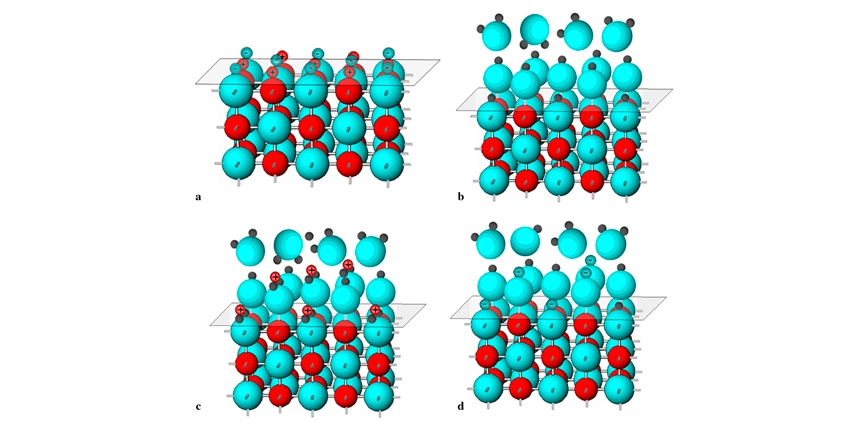

The mechanism of the formation of liquid phase growth agents: most of the growth agents are compact deposition of cubes and NaCl crystal structure. Due to the difference in the crystal structure, their “solubility” in Al2O3 is very small, and their content in the matrix is reduced by the method of impurity aggregation at the grain boundary.

With the continuous sintering, the number and area of grain boundaries decrease, the impurity concentration of grain boundaries increases and the eutectic temperature of grain boundaries decreases. When it reaches a certain limit, it becomes a liquid phase and increases the sintering temperature and sintering density.

The action mechanism of zirconia ceramic solid solution enhancer: if the lattice type is the same or similar to that of alumina, Cr2O3 and Fe2O3 can form infinite displacement solid solution with Al2O3, while TiO2 and MnO can form finite displacement solid solution with Al2O3, resulting in a certain degree of lattice distortion.

In addition, because these compounds are variable valence compounds, they can activate the lattice and reduce the sintering temperature. the important thing is that they can achieve densification and improve sintering through particle diffusion or interfacial movement.

Most of these additives are color enhancers, which will change the white state of ceramic sheets; because these compounds are variable valence compounds, they are easy to produce electron transfer in electric field and high temperature and high humidity environment, resulting in an increase in dielectric loss and a decrease in volume resistivity. Therefore, these compounds are not required in the formulation of Al2O3 ceramic substrates.

information

- Ceramic-to-Metal Assemblies: Unlocking the Secrets

- Application Fields of Silicon Carbide Ceramics

- High-Purity Alumina Ceramics: Powering Four Major Industries

- How is the surface roughness of alumina ceramics achieved?

- What are the advantages and applications of silicon carbide c…

- Advantages of advanced ceramic materials in ceramic substrate…

- Advantages and applications of alumina ceramic tubes for furn…

- Application of ZTA ceramic materials in the semiconductor ind…

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL