E-mail:admin@cerampart.com

Speed control of ceramic assembly machining

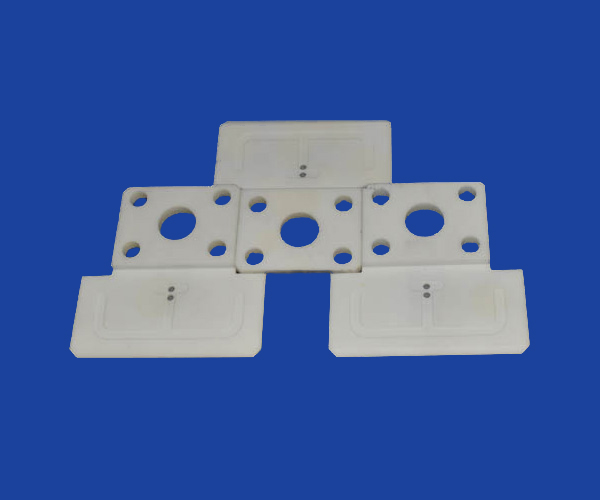

Time:202020-12-02Speed control of ceramic assembly machining

The processing speed of ceramic modules is becoming more and more efficient. However, to improve the processing speed of ceramic modules, it is also necessary to control the speed so as to ensure the smooth processing of ceramic modules. What aspects should we start from?

1. Flexible acceleration and deceleration control

In the machining of ceramic components, the system program directly realizes the specific automatic speed control function.In this way, to change the characteristics of the system acceleration and deceleration or add and subtract control to modify the NUMERICAL control program, so ordinary users can not make the CNC machine tools have the best acceleration and deceleration performance.Therefore, the flexible acceleration and deceleration control method proposed by us adopts the principle of database, divides the acceleration and deceleration control into two parts: acceleration and deceleration description and implementation, and separates the acceleration and deceleration description from the system program.In the numerical control system software, a general control channel which has nothing to do with the acceleration and deceleration database is designed, and the acceleration and deceleration calculation and trajectory control are completed independently by it.

2. Flexible automatic acceleration control

Set up acceleration curve, analytic curve and non-analytic curve, and store them in acceleration and deceleration curve library in the form of numerical table as samples.

3. Flexible automatic deceleration control

The acceleration control is also stored in the acceleration and deceleration curve library as a sample in the form of a number table.Reasonable automatic acceleration and deceleration control is an important part to ensure the dynamic performance of CNC machine tools.Due to the lack of flexibility, the traditional automatic acceleration and deceleration control based on fixed curve is difficult to ensure that the acceleration and deceleration process is compatible with the performance of the machine tool, and it is difficult to achieve the best dynamic characteristics of the machine tool.

As is known to all, ceramic components machining center is so far, no matter from the ceramic components processing precision, ceramic components machining efficiency, complex ceramic components of processing capacity and automation degree of ceramic components processing performance better on a nc machining equipment, so in order to improve the efficiency of workpiece processing ceramic components must be from the control speed is also very important.

information

- Ceramic-to-Metal Assemblies: Unlocking the Secrets

- Application Fields of Silicon Carbide Ceramics

- High-Purity Alumina Ceramics: Powering Four Major Industries

- How is the surface roughness of alumina ceramics achieved?

- What are the advantages and applications of silicon carbide c…

- Advantages of advanced ceramic materials in ceramic substrate…

- Advantages and applications of alumina ceramic tubes for furn…

- Application of ZTA ceramic materials in the semiconductor ind…

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL