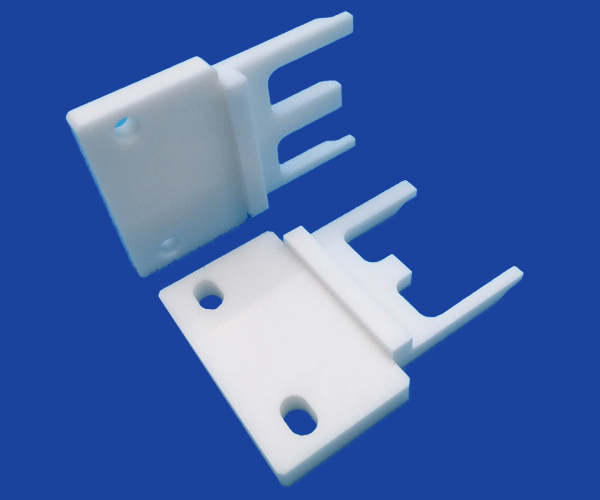

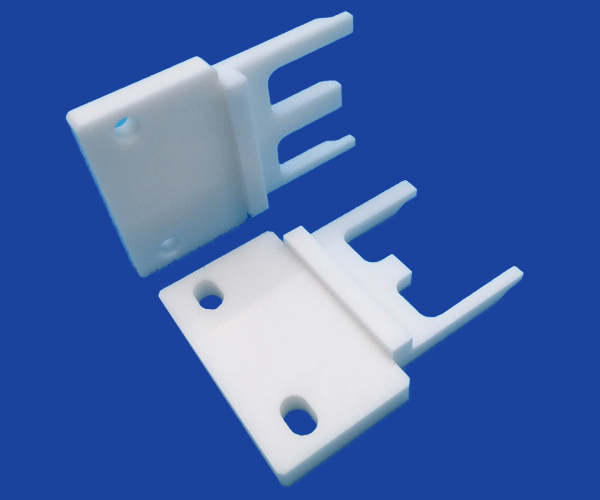

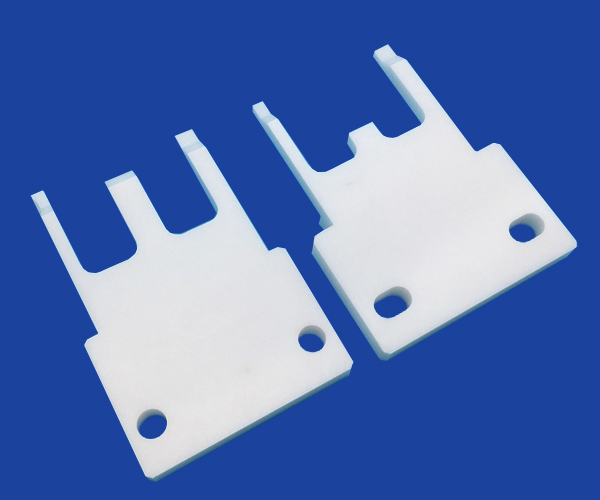

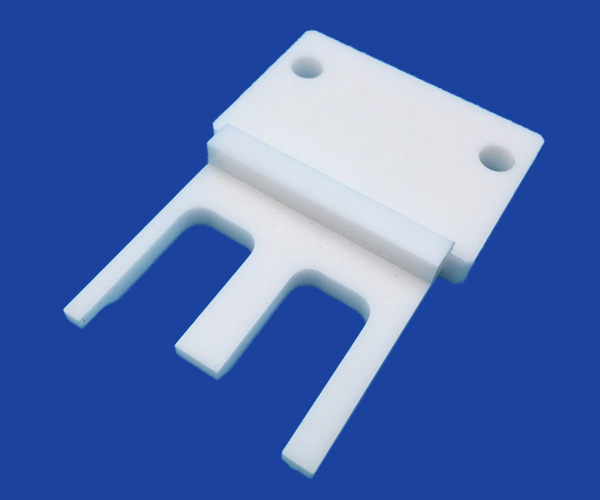

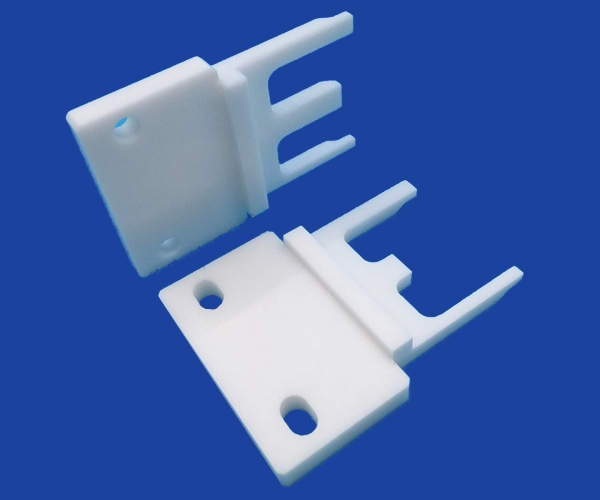

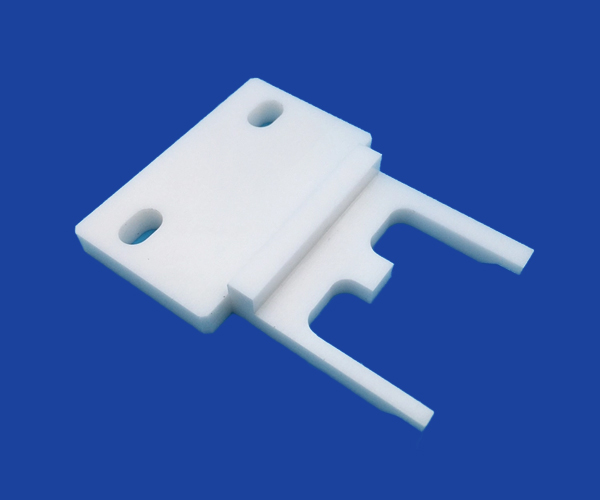

High Strength Zirconia Toughened Alumina ZTA Ceramic Guide Plate Machining Al2O3 Alumina Plates

ZTA (Zirconia Toughened Alumina) ceramic plate is a composite ceramic material formed by adding part of the stable zirconia (ZrO₂) to the alumina matrix. It combines the high hardness and wear resistance of alumina with the high toughness and thermal shock resistance of zirconia. It is widely used in aerospace, electronic power, machinery manufacturing and other fields.

Performance advantages of ZTA ceramic plate

1. Toughening characteristics

ZTA ceramic plate (zirconia toughened alumina ceramic) combines the high hardness of alumina and the high toughness of zirconium oxide. Compared with pure alumina ceramic, its crack resistance and fracture resistance are significantly improved. The addition of zirconium can effectively inhibit crack propagation, making the material show better reliability when subjected to mechanical stress or impact.

2. Thermal shock resistance

ZTA ceramic plate has better thermal shock resistance and can withstand rapid temperature changes without cracking or damage. This feature gives it a clear advantage in applications that need to experience frequent temperature fluctuations.

3. High flexural strength

The flexural strength of ZTA ceramic plate is usually higher than that of pure alumina ceramic, and it can withstand greater bending loads. This property makes it suitable for structural components that require high load-bearing capacity.

4. Wear resistance

Due to its combination of hardness and toughness, ZTA ceramic plates exhibit good wear resistance and are suitable for use in environments involving abrasive or erosive wear.

5. Adjustable material properties

The composition of ZTA ceramics can be adjusted to achieve specific material properties according to specific application requirements. This flexibility enables it to meet diverse application needs.

6. Weight reduction

The enhanced toughness and mechanical properties of ZTA ceramic plates allow the design of thinner and lighter components than pure alumina without affecting its performance.

Application areas of ZTA ceramic plates

1. Aerospace field

High temperature components: The high temperature stability and wear resistance of ZTA ceramic plates make them ideal materials for high temperature and high speed working environments such as engine nozzles and aviation bearings in the aerospace field.

Structural components: Its high strength and lightweight characteristics are suitable for manufacturing structural components such as anti-seismic supports and robotic arms.

2. Mechanical manufacturing field

Wear-resistant lining: ZTA ceramic plates can be used to manufacture wear-resistant linings for equipment with large material conveying volume and strong impact force, such as mining hoppers, coal powder conveying pipelines, etc.

Cutting tools: The high hardness and high temperature stability of ZTA ceramic plates make it an ideal material for making high-speed cutting tools, suitable for processing difficult-to-process materials such as cast iron and alloys.

3. Electronic power field

Packaging substrate: ZTA ceramic plates are widely used in semiconductor device packaging substrates due to their excellent heat dissipation, insulation and thermal shock resistance, such as electric vehicle IGBT, LED and other fields.

Ceramic splitter: In the field of chip packaging, ZTA ceramic splitters reduce the wear and replacement of ceramic splitter tips during wire bonding due to their excellent mechanical properties.

4. Biomedical field

Artificial joints: ZTA ceramic plates have good biocompatibility and corrosion resistance, and are suitable for manufacturing rigid components of artificial joints, providing good bone bonding and durability.

Dental restoration materials: ZTA ceramic plates have application value in dental implants, orthodontic brackets and other fields, combining the advantages of alumina with the high strength and toughness of zirconium oxide.

5. Chemical industry

Corrosion-resistant parts: The chemical stability of ZTA ceramic plates makes them suitable for manufacturing corrosion-resistant parts in chemical equipment, such as valves, pump bodies, etc.

Refractory materials: ZTA ceramic plates can be used to manufacture refractory materials such as fire bricks and refractory slurries, and are suitable for high temperature environments.

Application of ZTA Ceramics

· Aerospace:

Engine parts: used to manufacture combustion chamber linings, turbine blades, etc., to withstand high-temperature gas scouring and mechanical stress.

Thermal protection system: as thermal protection tiles, heat shields, etc., to block extreme high temperatures and protect spacecraft structures.

Structural components: used for wing leading edges, fuselage skins, etc., to reduce weight and improve flight performance.

· Electronic power:

Packaging substrate: in electric vehicle IGBT, LED and other fields, as DBC copper-clad substrate, to withstand high current capacity and temperature cycles.

Heating element: withstands higher starting power than pure alumina ceramics, suitable for high-power electronic devices.

· Mechanical manufacturing:

Wear-resistant lining: used in mine hoppers, coal powder conveying pipelines, etc., to resist material impact and wear.

Cutting tools: suitable for machining difficult-to-machine materials such as cast iron and alloys.

· Biomedical:

Artificial joints: rigid components used to manufacture artificial joints, providing good bone bonding and durability.

Features:

1) High strength and high toughness: The bending strength can reach more than 750MPa, and the fracture toughness is significantly higher than that of pure alumina ceramics.

2) Wear resistance: High hardness and good toughness, suitable for high-speed friction and high-wear environments.

3) Thermal shock resistance: Able to withstand rapid temperature changes, suitable for extreme thermal environments.

4) High temperature resistance: High melting point, stable strength and hardness at high temperatures.

5)Customizability: The composition can be adjusted to meet different application requirements.

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic sheet,plates,block or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL