E-mail:admin@cerampart.com

Factors affecting the ceramic properties of insulating ceramics

Time:202019-11-28

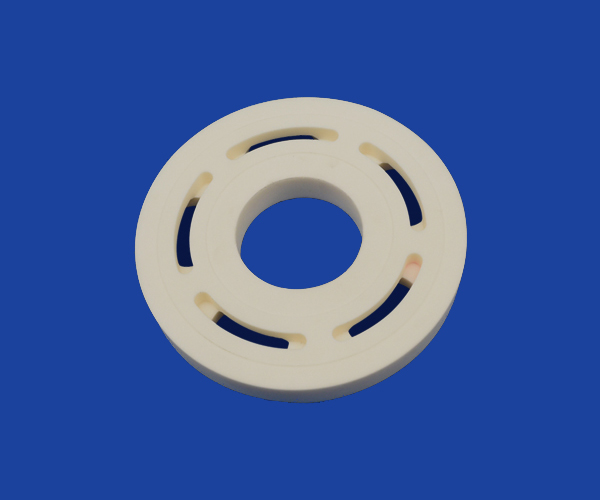

Insulating ceramics, also known as device ceramics, are high density insulating ceramics.Alumina ceramics are one of the most widely used electronic ceramics.Electrical insulating ceramics occupy a certain proportion in electronic ceramics, while electronic ceramics occupy a large proportion in high-tech ceramics.Insulating ceramics: high resistivity, low high frequency loss, high resistivity, used for integrated circuit board, packaging, high frequency insulating ceramics, etc.Insulating ceramics are widely used in the power electronics industry for the installation, support, protection, insulation, isolation and physical connection of electrical appliances.For example, insulators, insulation sleeves, resistance substrates, coil frames, power supply tube clamps, integrated circuit boards, etc.

Electrical insulating ceramics are widely used in dielectric ceramics.Alumina ceramics are mainly used for insulator, resistance, integrated circuit board, package tube, shell and other electronic components and the matrix, shell, fixed parts, seals or insulation parts of the circuit.Physical isolation of conductors in an electrical or electronic circuit.In addition, it also plays a conductor mechanical support, heat dissipation and circuit environmental protection role.Generally speaking, the ceramic that can have above effect is called insulating ceramic.

Most ceramics are insulators.Electrons close to room temperature do not readily jump to the conduction band due to thermal excitation.Therefore, ionic conductivity generated by ion diffusion is the main form of conductivity to be considered in insulating ceramics.Under the influence of the valence state, size and diffusion coefficient of the ions, the smaller the charge and volume of the ions, the easier the diffusion and the smaller the activation energy.Affected by microstructure: mainly depends on grain boundary phase and surface porosity.Glass should minimize the presence of alkali metal oxides, and choose a porous, non-absorbent dense material.

information

- Ceramic-to-Metal Assemblies: Unlocking the Secrets

- Application Fields of Silicon Carbide Ceramics

- High-Purity Alumina Ceramics: Powering Four Major Industries

- How is the surface roughness of alumina ceramics achieved?

- What are the advantages and applications of silicon carbide c…

- Advantages of advanced ceramic materials in ceramic substrate…

- Advantages and applications of alumina ceramic tubes for furn…

- Application of ZTA ceramic materials in the semiconductor ind…

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL